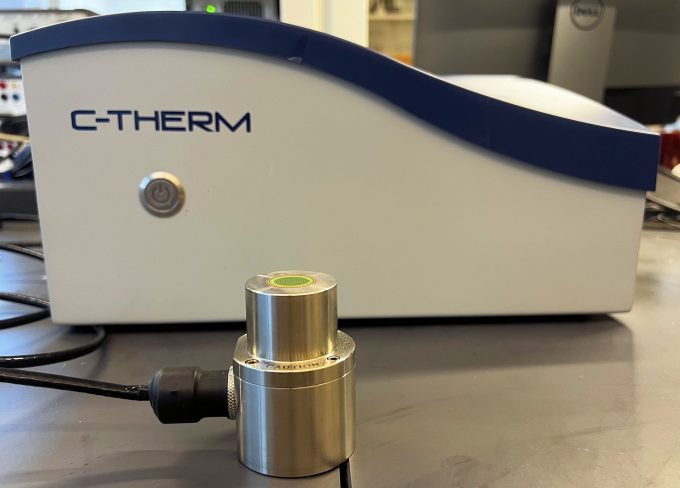

C-Therm Thermal Conductivity Analyzer

The Modified Transient Plane Source (MTPS) technique is used to analyze the thermal thermal conductivity and effusivity of materials. It utilizes a single-sided, interfacial heat reflectance sensor to apply a brief, constant heat source to the sample, with measurement pulses typically lasting 1 to 3 seconds. This approach offers a comprehensive assessment of the sample material’s heat transfer properties and conforms to ASTM D7984.

The instrument measures the thermal conductivity and effusivity of solid, liquid, powder, and paste samples. It measures thermal conductivity within the range 0 to 500 W/mK, while the effusivity measurement range is 5 to 40,000 Ws½/m²K. The temperature range is -50 to 200 degrees C. The precision of the thermal conductivity measurement is better than 1% and the accuracy is better than 5%.

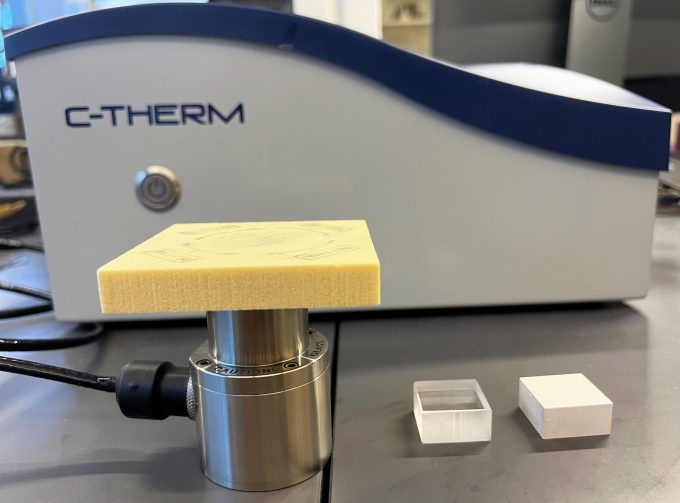

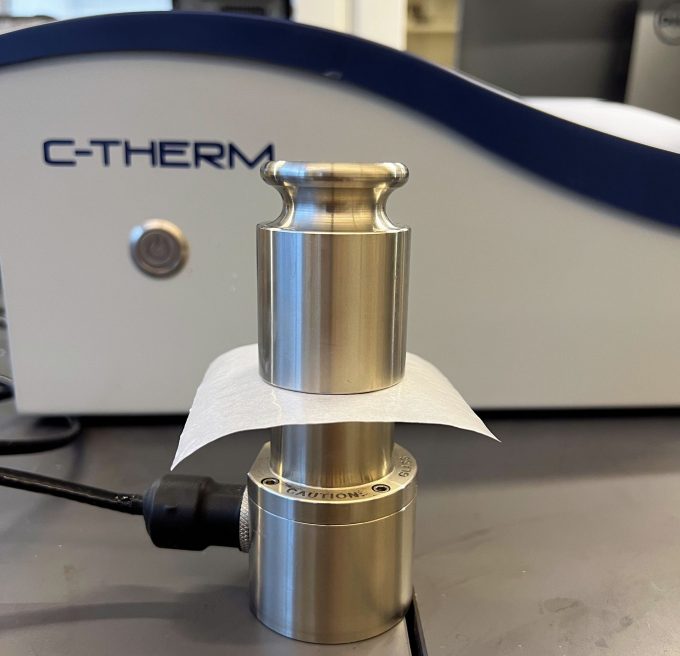

The minimum sample testing size is a diameter of 17 mm (0.67 inches), with no maximum size restriction. The minimum sample thickness is about 0.5 mm (0.02 inches), though this is dependent upon the thermal conductivity of the material. There is generally no practical maximum thickness limit. A solid sample needs to have a flat side. Powder samples are measured under a common pressure since the compaction of the sample is a significant variable otherwise.

The sample is positioned on the sensor coil, and a known current is applied to the coil’s spiral heating element to generate a small amount of heat. A guard ring encircles the sensor coil to facilitate one-dimensional heat transfer into the sample. The applied current causes the temperature to increase at the interface between the sensor and the sample, resulting in a change in the sensor element’s voltage drop. The rate of voltage increase in the sensor is utilized to determine the sample’s thermal properties, with the voltage being calibrated to temperature by the factory. Thermal conductivity is inversely related to the rate of temperature increase at the sensor-sample contact point. The voltage serves as a temperature proxy, rising more sharply for materials with lower thermal conductivity (e.g., foam) and having a flatter slope for those with higher thermal conductivity (e.g., metal).

Applications

- Aerogels

- automotive components

- batteries

- composite materials

- insulation

- explosives and propellants

- geological samples

- fabrics

- liquids

- powders

- metals

- nanomaterials

- metal hydrides

- nuclear materials

- phase change materials (PCMs)

- polymers

- rubber

- thermal interface materials (TIMs) and dielectrics

- thermoelectric materials

- additive manufacturing

- biomaterials

- building materials

- tests for material uniformity

- test of inaccessible internal materials (particle distributions in composites)

- service life monitoring

ASTM Standard Test Methods

ASTM D7984-21 Standard Test Method for Measurement of Thermal Effusivity of Fabrics Using a Modified Transient Plane Source (MTPS) Instrument

Dr. Priyanshu Banerjee provides our thermal conductivity measurements. You are invited to discuss your thermal conductivity measurement needs with him at Priyanshu@andersonmaterials.com or by calling him at 410-740-8562.