AME performs sensitization testing according to ASTM G108. Sensitization of stainless steels occurs when they are improperly heated, leading to the excessive formation of chromium carbides at the grain boundaries. In the case of austenitic stainless steels types 304 and 304L too much time spent between 425°C and 815°C increases carbide inclusion number and size. As the available chromium is converted to chromium carbide the outermost portions of the grains become chromium-depleted and more susceptible to corrosion. The form of corrosion that results from sensitization is known as intergranular corrosion (IGC) or intergranular attack (IGA).

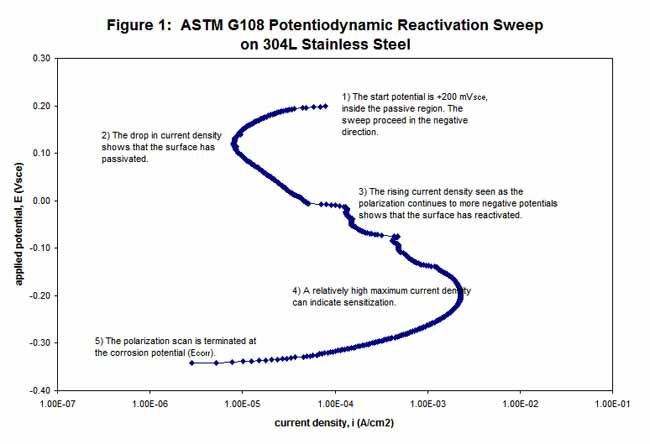

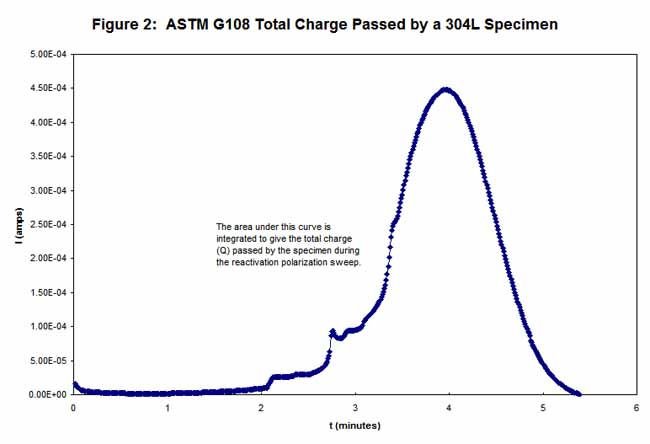

The ASTM G108 test involves metallographic preparation of the specimen(s) followed by electrochemical reactivation in an aggressive electrolyte. The freshly polished and cleaned specimen is stepped from its open circuit potential to a passivating potential, then reactivated by performing a polarization sweep back to the corrosion potential as shown in Figure 1. The initially decreasing current density indicates passivation, while the rapid increase in current density at lower potentials indicates reactivation of the surface. Higher maximum current densities imply a greater degree of sensitization. The polarization data shown in Figure 1 is collected at a constant sweep rate. As a result it is also possible to plot total current as a function of time as shown in Figure 2. Integration of the area under the resulting curve gives the total charge passed during reactivation. Once the polarization is completed, the specimen is examined metallographically in order to examine the grain boundaries and inclusions, and to perform a grain count.

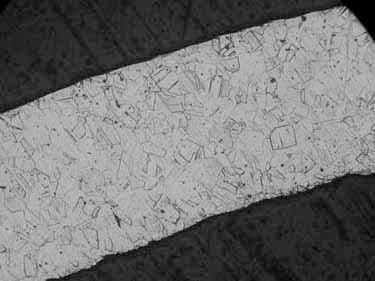

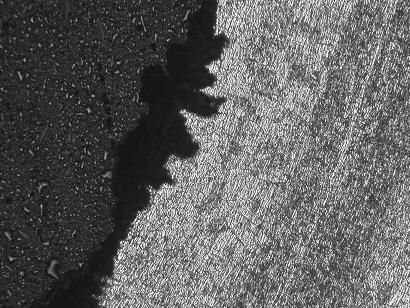

Figure 3 shows a specimen after the polarization test. The grain structure is faintly visible. In such cases ASTM G108 allows for surface etching to better reveal the grain boundaries; a mildly sensitized specimen etched by oxalic acid is shown in Figure 4. A specimen that suffered a greater degree of sensitization is shown in Figure 5. This specimen also illustrates the grain loss associated with IGC. The total specimen area, the total charge passed during reactivation, and the grain size determined in accordance with ASTM E112 are all necessary to calculate the degree of sensitization of a 304 or 304L stainless steel specimen.

Interpretation criteria are provided in the standard, but final acceptance criteria must be established by the user. Mitigating factors for interpretation include possible contributions from intragranular (matrix) precipitates and possible crevice attack between the specimen and the potting compound. While these may drive up the total charge value, they do not contribute to IGC. Consequently, it is always important to consider the electrochemical results together with the post-polarization metallographic inspection to understand the true degree of sensitization in a specimen.