TGA Analysis or Thermogravimetry

- TGA analysis measures the weight of a material sample, commonly either as a function of increasing temperature, or isothermally as a function of time, in an atmosphere of nitrogen, helium, air, or other gases. Any weight changes can be accurately measured.

- Thermal gravimetric analysis can be interfaced with a mass spectrometer RGA to identify and measure the vapors generated, though there is much greater sensitivity when the mass spectroscopy heating is performed in an ultrahigh vacuum system

- Inorganic materials, metals, polymers and plastics, ceramics, glasses, and composite materials can be analyzed by TGA analysis.

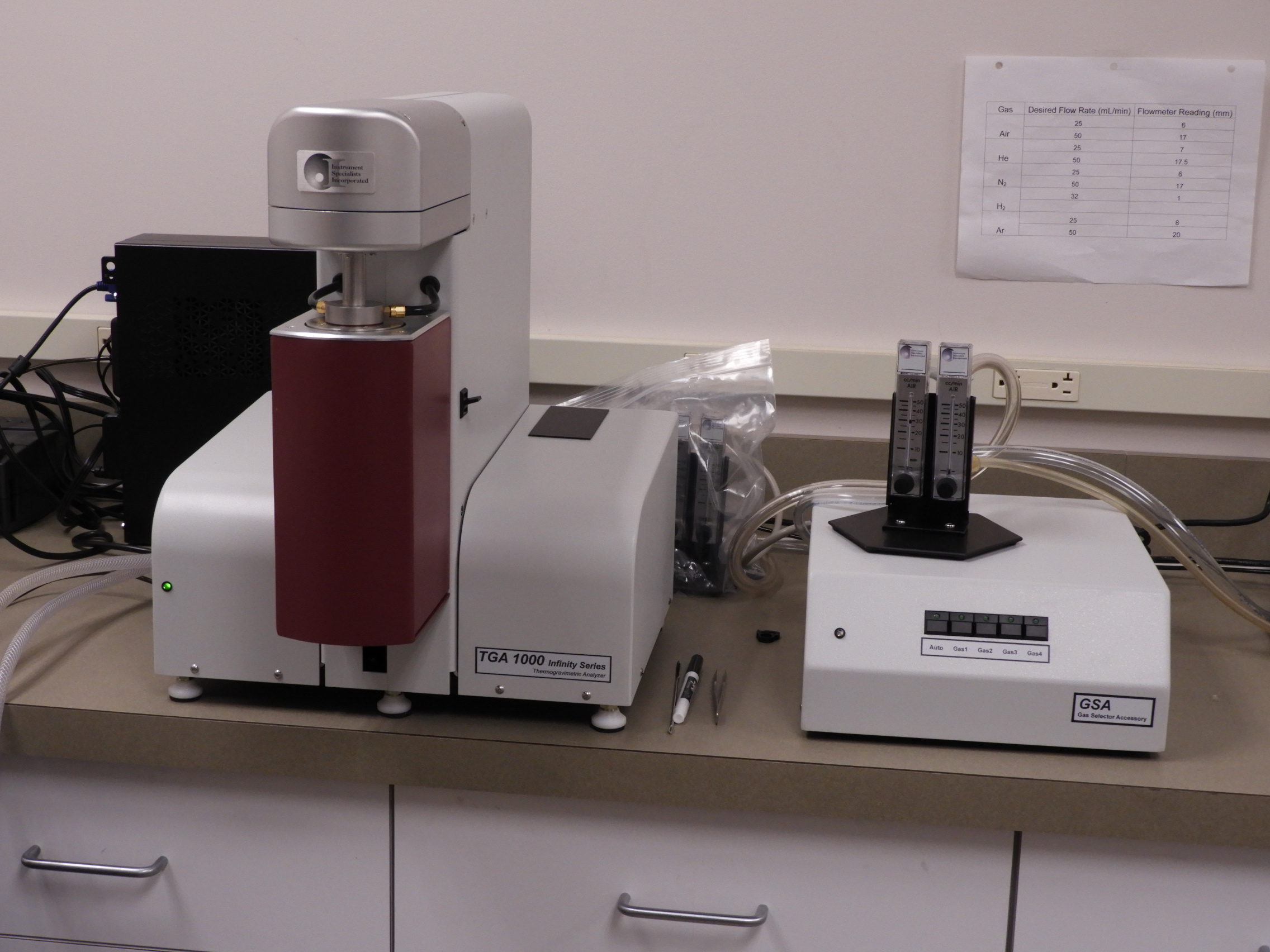

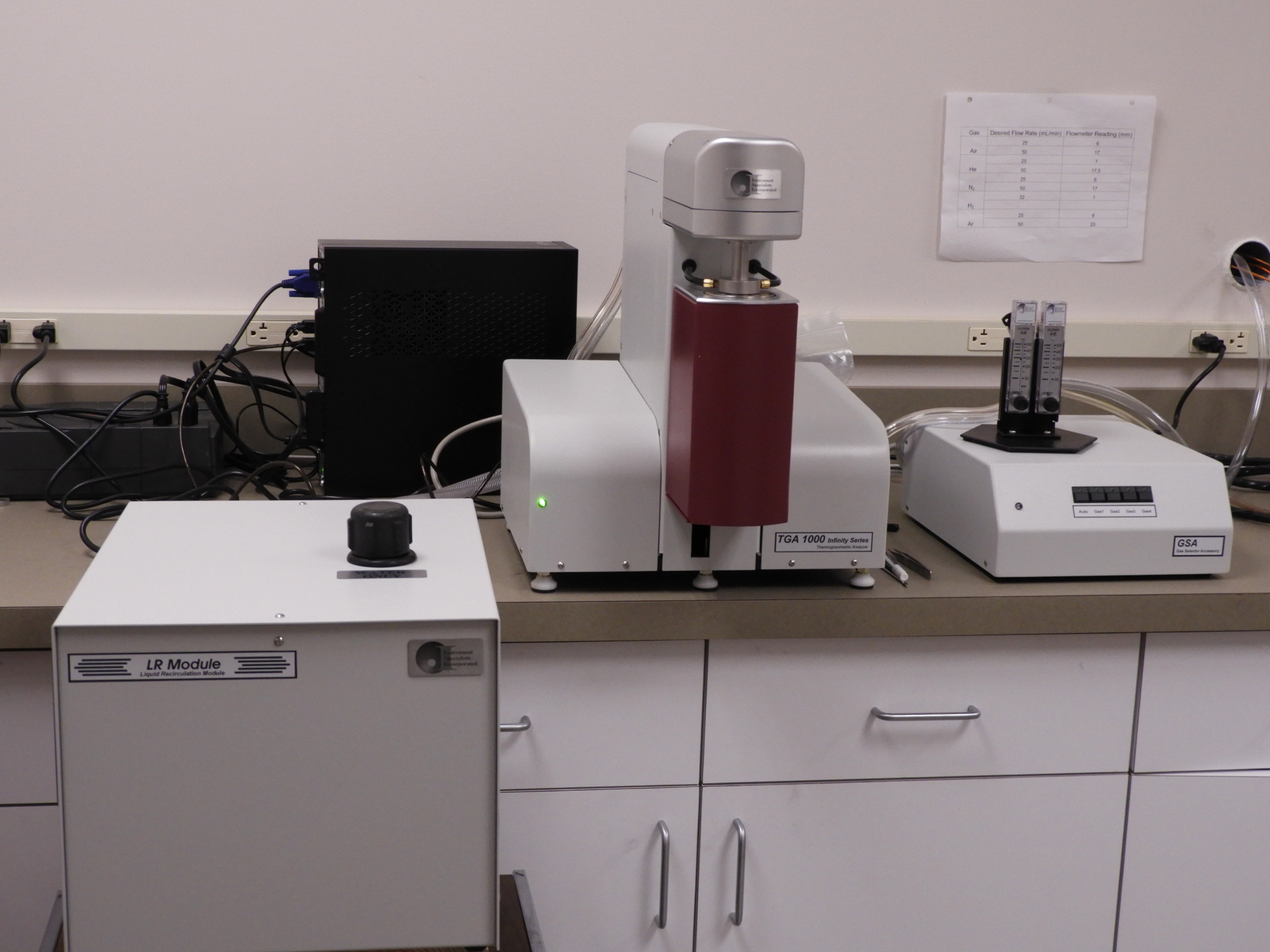

- Temperature range from ambient to 900°C routinely. The maximum temperature is 1000°C on our instrument. The heating rate range is from 0.1°C/min to 100°C/min. We have access to an instrument with an upper temperature limit of 1500°C when you need it.*

- Sample weights up to 400 mg. Sample weights of more than 10 mg are preferred, but excellent results are sometimes obtainable on 1 mg of material.

- Weight change sensitivity of 0.0001 mg or 0.1 micrograms.

- The temperature is measured with a Type K: Chromel/Alumel thermocouple with a temperature accuracy of 0.5°C.

- The four gas switching accessory allows the programmed switching of gases during a TGA analysis procedure

- The TGA furnace is cooled with recirculating water.

- Samples can be analyzed in the form of powder or small pieces so the interior sample temperature remains close to the measured gas temperature.

Applications of TGA Analysis or Thermogravimetry

- Determines temperature and weight change of decomposition reactions, which often allows quantitative composition analysis.

- Used for compositional and formulation analysis of multi-component materials and blends.

- May be used to determine water content or the residual solvents in a material.

- Allows analysis of reactions with air, oxygen, or other reactive gases (see illustration below).

- Can be used to measure evaporation rates as a function of temperature, such as to measure the volatile emissions of liquid mixtures.

- Helps to identify plastics and organic materials by measuring the temperature of bond scissions in inert atmospheres or of oxidation in air or oxygen.

- Used to measure the weight of fiberglass and inorganic fill materials in plastics, laminates, paints, primers, and composite materials by burning off the polymer resin. The fill material can then be identified by XPS and/or microscopy. The fill material may be carbon black, TiO2, CaCO3, MgCO3, Al2O3, Al(OH)3, Mg(OH)2, talc, Kaolin clay, or silica, for instance.

- Can measure the fill materials added to some foods, such as silica gels, cellulose, calcium carbonate, and titanium dioxide.

- Can determine the purity of a mineral, inorganic compound, or organic material.

- Distinguishes different mineral compositions from broad mineral types, such as borax, boric acid, and silica gels.

- Provides quality control to ensure products meet their materials specifications.

- Determines polymer degradation in regrind or recycled polymer resin in comparison to virgin resin. Often used for this purpose in conjunction with DSC.

- Purity analysis of carbon nanotubes (CNT) and comparison of CNT samples from different manufacturers, batches, and processes.

- Liquid or gas absorbed in porous material can be desorbed as a function of temperature with measured weight loss

ASTM Test Methods Using TGA Analysis or Thermogravimetric Analysis

- ASTM D2584 – Standard Test Method for Ignition Loss of Cured Reinforced Resins

- ASTM D3850 – Thermogravimetric Method (TGA)

- ASTM D5967 – Standard Test Method for Evaluation of Diesel Engine Oils in T-8 Diesel Engine

- ASTM D6370 – Standard Test Method for Rubber-Compositional Analysis by Thermogravimetry (TGA)

- ASTM D6375 – Standard Test Method for Evaporation Loss of Lubricating Oils by Thermogravimetric Analyzer (TGA) Noack Method

- ASTM E1131 – Standard Test Method for Compositional Analysis by Thermogravimetry

- ASTM E1641 – Standard Test Method for Decomposition Kinetics by Thermogravimetry Using the Ozawa/Flynn/Wall Method

- ASTM E1877 – Standard Practice for Calculating Thermal Endurance of Materials from Thermogravimetric Decomposition Data, used to estimate polymer lifetime

- ASTM E2008 – Standard Test Method for Volatility Rate by Thermogravimetry

California Department of Pesticide Regulation TGA VOC Tests:

We have a web page dedicated to this TGA analysis test here.

Illustrative Example: Determination of weight % of composite material components by TGA Analysis

Thermogravimetric analysis was used as one of several complementary techniques in the identification of an unknown polymer composite, which microscopy revealed had fiberglass content. XPS identified the composition of the fiberglass and revealed the presence of CaCO3 as residues of a lower temperature TGA run than the high temperature run shown below. FTIR indicated a polymer consisting of polyester and, probably, polystyrene. TGA was then performed on the material to find the weight percent of each material. The sample was heated from room temperature to 900°C at a rate of 5°C/min in air. The TGA analysis curve (below) is labeled in terms of the identity of the components. Here polyester (71% of the polymer), polystyrene (29% of the polymer), fiberglass (22.9% of the whole) and CaCO3 (49.3% of the whole) were easily identified by their different temperatures of combustion or evaporation. The combustion of the styrene polymer component produced enough energy that the temperature momentarily increased more than the programmed rate, which accounts for the unusual shape of the curve due to the cooling that followed the reactive overheating. The remaining material after the TGA analysis was completed was confirmed by XPS to consist only of CaCO3. The results obtained for the polymer matrix match the common blend co-polymer of 70% polyester and 30% polystyrene by weight.

Characterizing Fiberglass Reinforced Nylon-6 Pellets for Injection Molding

Purity of a Calcium Carbonate Sample

Contact: Vaidheeshwar Ramasubramanian, email: vaidheeshwar.r@andersonmaterials.com

*1500°C TGA Analysis (Referral)

- Sample capacity of 200 mg

- Ideal sample weight from 10 to 50 mg

- Balance sensitivity of 0.1 microgram

- Temperature range from ambient to 1500°C