XPS Depth Profile Illustrative Example: Multi-layer Reflective Coating Analysis

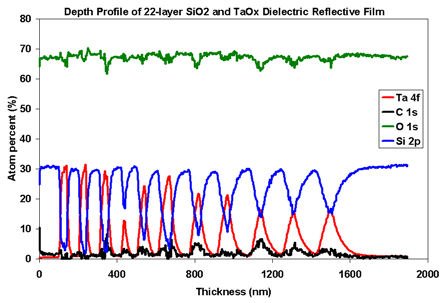

Figure below shows the XPS depth profile of a 22-layer SiO2 and tantalum oxide (Ta2O5) dielectric reflective film on the interior wall of a hollow quartz material. Depth profiles are used to determine the elemental composition as a function of depth. A rastered, differentially pumped argon ion gun at 4keV was used to sputter the surface of the reflective dielectric film. The sputter rate of SiO2 was used to express the thickness of the layers in the dielectric film.

From the figure of the XPS depth profile, it is observed that there are alternating SiO2 and non-stoichiometric TaOx layers in the dielectric film, SiO2 being the first layer. Also, outer layers are thinner than the inner layers, though the first SiO2 protective layer is thicker than the other outer SiO2 layers. The depth resolution decreases with depth because of local variations in the propagation of the sputtered surface.

The 8th layer of the XPS depth profile should have been a TaOx layer, but it was a mixed layer instead. Ta had a local maximum there, which was less than the Si concentration at that depth. It is also observed that the oxygen concentration in the TaOx layer is less than that in the SiO2 layer, despite the fact that it should be 25% greater. On the other hand, the carbon concentration in the TaOx layers is greater than that in the SiO2 layers. Generally, it was greater in the deeper layers, though it fluctuated from layer to layer. The Ta and C concentration variations were due to a poorly operating valve system in the deposition chamber of our customer’s subcontractor.