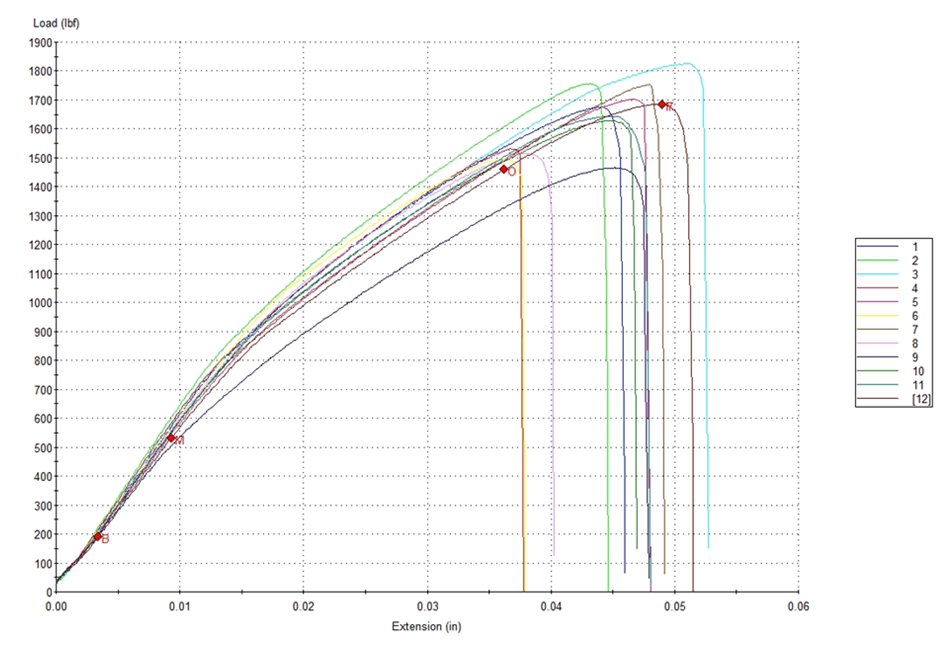

The apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading was measured following the ASTM D 1002 standard. A set of 12 specimens of 316L stainless steel coupons were prepared for epoxy adhesive bonding by following the ASTM D1002 standard and the curing recommendations of the epoxy adhesive manufacturer. They were then subjected to increasing tension until the adhesive bond failed, providing a measure of the adhesive bond strength of each sample.

Preparation of the test specimens

The surface preparation consisted of polishing with abrasive paper, rinsing with water and isopropyl alcohol, and drying well in the laboratory air. The one-component epoxy adhesive was applied to the metal coupon surface for bonding, then the opposing coupon was placed on top of it with 0.5 inches of overlap. A weight was placed over the bonded area and some of the epoxy adhesive squeezed out over the surface of the coupons beyond the bonded area, but this adhesive did not bond to the end surfaces of the coupons. Thus, the area of bonding was well-defined. The specimens were cured at 176 °C for 10 minutes in an oven.

ASTM D1002 Test Procedure

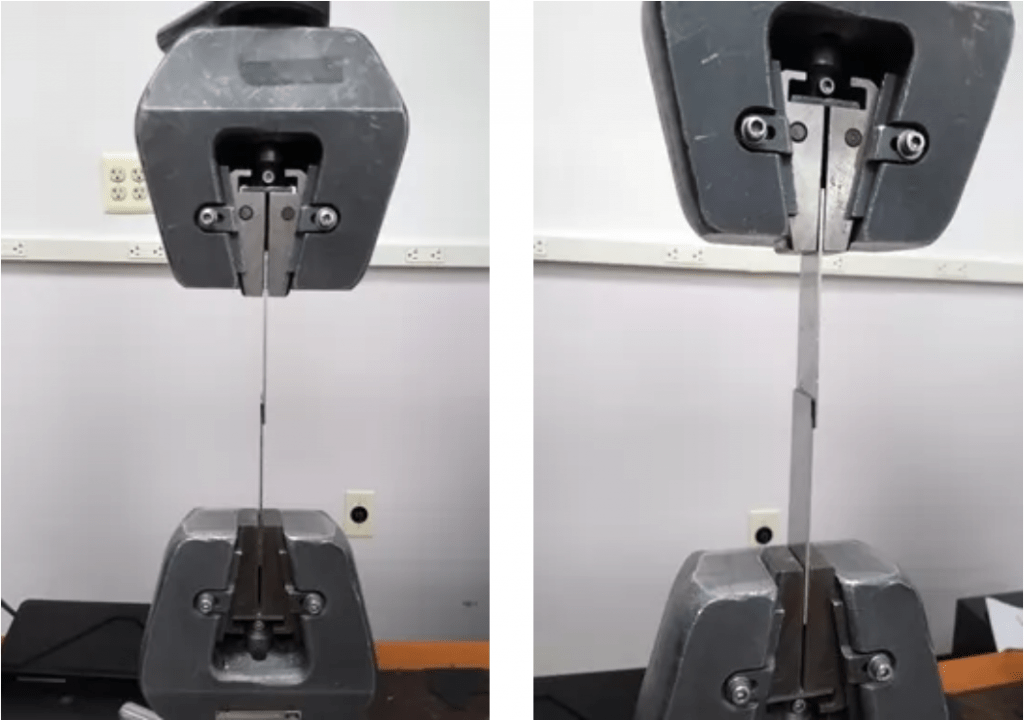

As defined by ASTM D1002, the test was run at a crosshead speed of 1.3 mm/min until failure in an Instron Model 1125 Universal Testing Instrument with a 10,000 lb. load cell. One inch from both end of each specimens was placed in the mechanical wedge action grips with coarse serrated faces for the run. Figure 1 shows the image of one of the specimens before a test run.

Figure 2 shows the results of the lap shear strength of adhesively bonded 316L stainless steel specimens.

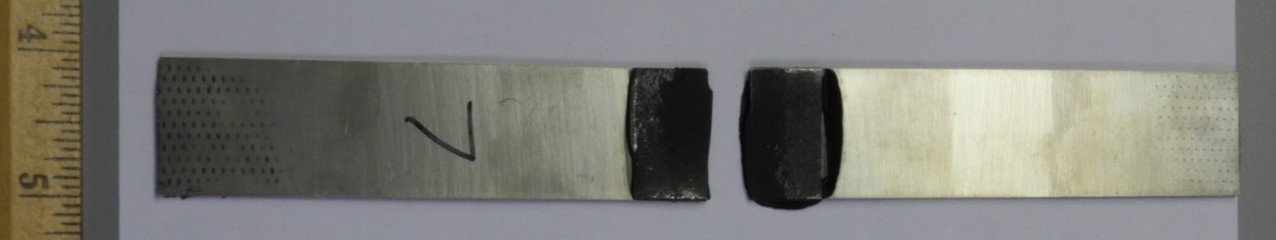

The failure mode of the specimens is assigned by the scientist after examining the surfaces of the test coupons after the failure. An image of a representative test specimen after the failure is provided in Figure 3.

Please contact Vaidheeshwar Ramasubramanian, Ph.D., anand@andersonmaterials.com or complete a contact form on our “Contact Us” page to discuss your mechanical testing needs.