Fourier Transform Infrared Spectroscopy (FTIR) is an analytical technique used to identify organic, polymeric and some inorganic materials. FTIR irradiates a material with infrared light over a range of wavelengths and measures the absorption as a function of the wavelength. The wavelength of absorption is characteristic of atomic bonding configurations. As a result, an FTIR spectrum gives information on the chemical bonds found in a substance and thus allows its identification. Unknown substance analysis is one of the very common uses of FTIR spectroscopy. Our FTIR testing services make a powerful materials analysis spectroscopy available for your materials problem-solving needs.

Advantages of FTIR Spectroscopy Analysis

- Requires a very little material to get a good spectrum result. For example, a 1 mm by 1 mm plastic piece, or drop of liquid is more than enough sample to be analyzed by FTIR spectroscopy.

- Quickly identifies if two or more materials are the same or different. Most commonly these materials are plastic, rubber, sealant, paint, adhesive and other organic chemicals. These materials can be found in packaging, hoses, tapes, containers, textiles, sport equipment, medical equipment parts and many other products.

- No or minimal sample preparation, especially when using attenuated total reflectance (ATR).

- With ATR-FTIR all types of samples such as liquids, solids, powders, pastes, pellets, beads, slurries, fibers, and foils can be analyzed.

- With our extensive library of FTIR spectra, it is easy to identify an unknown chemical by scanning the unknown spectrum against the library spectra for a match.

Uses of FTIR Spectroscopy Analysis

- Deformulation or reverse engineering of polymers, rubbers, and other materials in conjunction with TGA, DSC, GC-MS, and sometimes XPS.

- Identification of plastics and additives in plastics.

- Assessment of molecular degradation.

- Investigation of migration related issues for plasticizer, slip agents, fire retardants, or other chemicals.

- Identification of surface coatings or contaminants.

- Unknown substance analysis

- Quality control (QC) analysis to verify if materials meet specifications promised by supplier.

- Identification of components in automobiles such as epoxies, rubber seals and O-rings, tires, paints, fabrics and more.

- Identifying inorganic fill materials in polymer matrix composites.

- Identification of components in materials and chemical mixtures in combination with solvent extraction, Soxhlet extraction, heating, dissolving, and centrifugation and other techniques.

- Measuring degree of conversion for polymers by free radical polymerization.

- For certain materials, FTIR spectroscopy can be used for quantitative analysis.

Comparative Analysis by FTIR Spectroscopy

FTIR spectroscopy can be used to compare samples to determine the authenticity of a sample material. For example, a quality material may have been specified, but an independent contractor performing the job might substitute a less expensive or an easier to use material. FTIR testing can determine whether this has happened. Or a material used may have undergone unexpected degradation and FTIR analysis can be used to see if the degraded material had been the material specified or not. Or a repair of material may require that a match with the original material be discovered or a repair may have been made with an inferior material. FTIR testing can answer such questions.

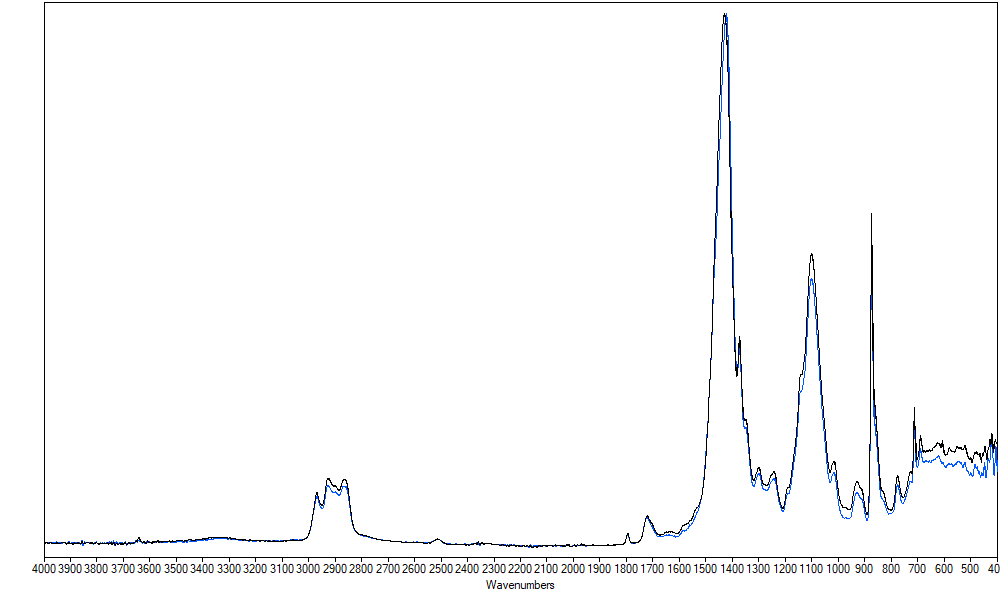

Here is an example of a comparative analysis of a sealant from a field application site and a brand new, freshly cured sealant. The customer was concerned that the degradation of the sealant used on a sea shore building might be due to the substitution of a sealant for the sealant specified. By comparing the FTIR spectra of these two samples, one can determine whether the authentic or agreed upon sealant was used during the construction.

In this case, the ATR-FTIR analysis made it clear that the chemical content in the sample from the application site and that of the control sample are the same. The peaks for the chemicals show up in the same wavenumber values with only slight differences in strength.

Unknown Analysis by FTIR Spectroscopy

In the case of an unknown sample analysis, the spectrum of an unknown material can be compared with the database spectra. Generally, a good match confirms the identity of the material or a match at least identifies a similar material.

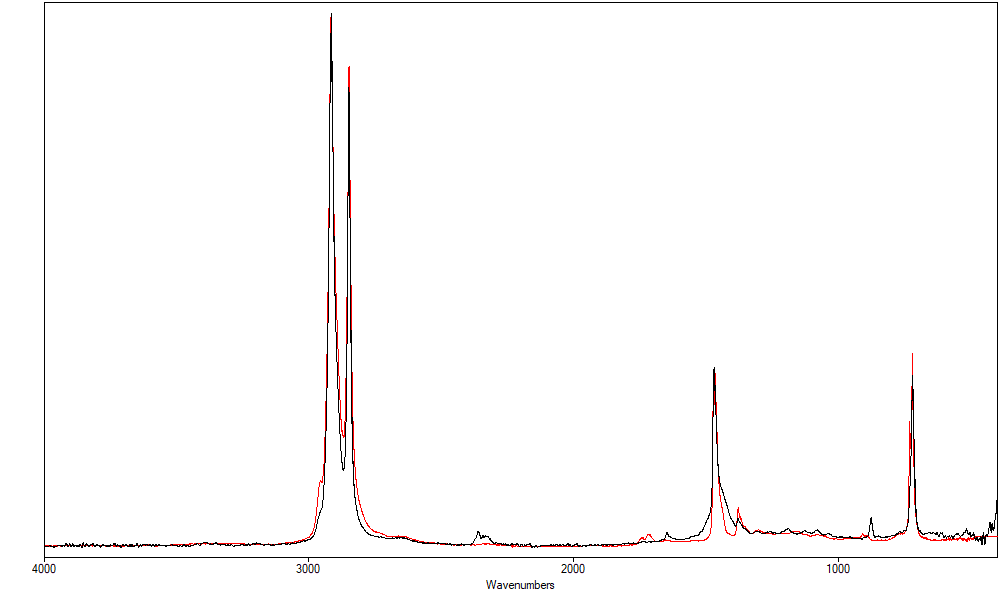

Here is a plastic bag sample, for which the red material of the zipper line was to be determined using FTIR testing.

The customer wanted to know if the red plastic of the zipper line was substantially different from the general bag polymer and what was it. The FTIR spectrum of the red zipper material quickly determined it to be polyethylene when the FTIR Instrument software compared its spectrum with the database spectra. While the red zipper line has a dye, only the type of base polymer was identified in this study. The dye might have been identified using GC-MS. Generally, the type of plastic used in many products can be quickly identified by FTIR analysis.

Polymer Composite Analysis by FTIR Spectroscopy

Polymer composites may contain organic and synthetic or natural inorganic materials in a polymer matrix. By using FTIR spectroscopy the components of polymer matrix composites can be identified.

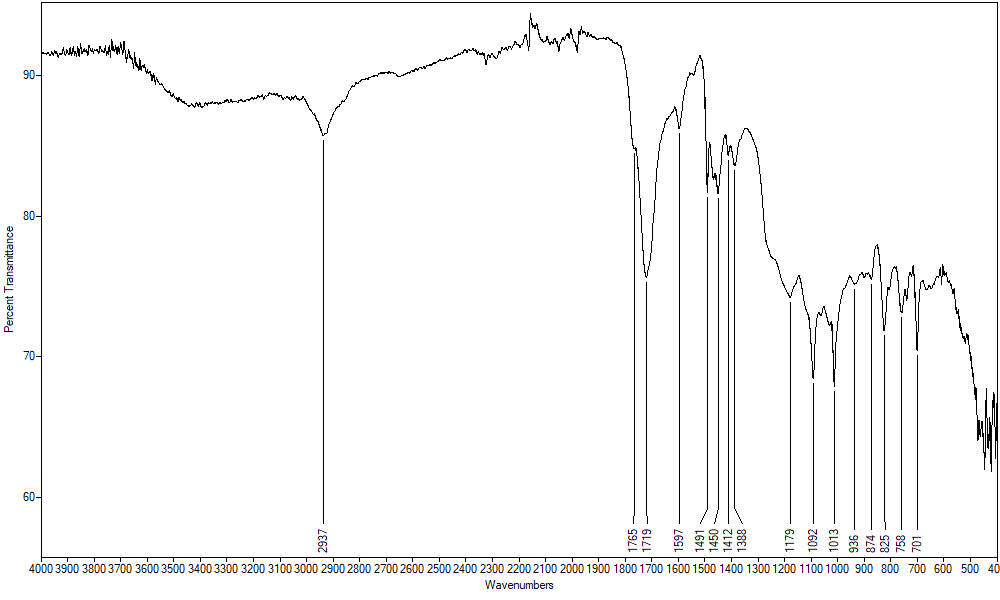

Here is an example of a polymer matrix composite analysis for a failed epoxy lined tank in a chemical treatment plant. The ATR-FTIR spectrum is presented in Figure 6 in transmittance mode. During sample preparation it appeared there was fiberglass content in a layer of the liner sample and other layers with a different appearance. Samples were taken from the liner in these different appearing layers. The ATR-FTIR spectrum of the composite material shows that there are many functional groups that are found in epoxy vinyl ester polymers. Moreover, the strength and presence of ether absorbance peaks and the non-existence of epoxide peaks gives proof that the resin is a well-cured epoxy vinyl ester polymer. This was additionally checked by DSC analysis which is not provided here.

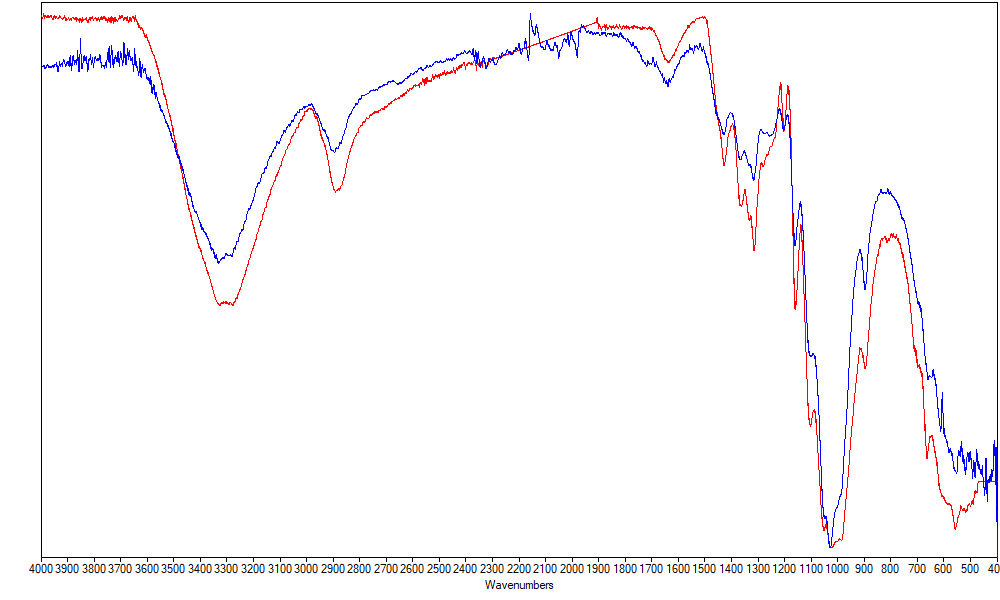

Subsequently, another ATR-FTIR spectrum was taken for a part of the sample rich in organic fibers removed from the liner. It is a good match with the spectrum of α-Cellulose from the database, which is presented in Figure 7.

In conclusion, by microscopic observation and ATR-FTIR spectra, it was concluded that the composite material includes fiberglass, cellulose, and the epoxy vinyl ester polymer.

FTIR Analysis Service

Anderson Materials Evaluation has a JASCO 6100 Infrared spectrometer equipped with a Golden Gate Attenuated Total Reflectance (ATR) accessory. The ATR-FTIR instrument has spectrum libraries contained in Fiveash Data Management’s ATR Databases. Indeed, for your FTIR spectroscopy analysis needs, we can be your go-to FTIR analysis laboratory for FTIR testing services for polymers, lubricants, coatings, adhesives and many other chemical substances and composites.

When necessary, we can use chemical separation and extraction techniques to find out more information about your materials and substances. Our PhD scientists put their research experience and problem-solving skills to work in identifying and understanding your materials problems or challenges. We then provide you with comprehensive analysis reports directed at providing you the understanding you need to take advantage of the analyses performed by us.

Please contact us for more information and assistance with your materials analysis needs.