Anderson Materials Evaluation has analyzed extensive materials and compounds for many different consumer goods customers. Below are some of the different types of companies and problems we have worked with in our over 25 years of experience:

Automotive & Boating

One type of consumer goods customers we work with is the automotive industry solve a variety of materials problems and develop improved products. We have done extensive work with our auto industry partners to resolve failure and defect issues. Examples include identifying causes of adhesive bonding problems, corrosion, and plastic degradation. We have assisted automotive and industry R&D organizations with the characterization of hard alloys at various stages of wear and stress testing in applications ranging from engine components to rollercoaster parts. Our team has also characterized coatings used to reduce wear and friction in high-performance engines, identified wear particles, and analyzed the surface chemistry of components ranging from windshield glass to braking materials.

In addition, Anderson Materials has performed work for clients in the boating industry. Our boating industry work has included composite materials inspections, propeller shaft failures, adhesive bonding issues, and corrosion issues.

We have performed analyses and investigations for many companies in the industry, including General Motors, Honda, Carlisle, JE Pistons, and Pilkington. See a complete list below. We are ready to assist with a wide-range of auto manufacturing, auto parts and boating industry materials problems. Please contact us to discuss your company’s needs.

Food & Beverage

Another type of consumer goods customers we work with is the Food and Beverage industry. Anderson Materials Evaluation has analyzed extensive materials and compounds related to packaging, food and beverage ingredients, and handling and processing equipment. We have examined packaging materials to verify proper thermal properties, solved thermal or ultrasonic sealing and adhesive bonding problems, and validated integrity and cleanliness. AME has worked with customers to characterize their food products, including to identify and verify the chemistry of the food product or inert additives, and determining the size and shape of food product materials particles (a favorite was SEM imaging of chocolate). AME also has assisted our customers in solving numerous problems related to processing and handing of products, including corrosion, contamination, excessive wear, cleaning effectiveness, coating integrity, and sensor and electronic controls issues.

We have handled projects for Grace Materials Technologies, Winpak, Monsanto, the FDA, and a number of popular food and beverage brands. See a complete list below.

Personal & Household Goods

Anderson Materials Evaluation has partnered with numerous companies to improve their consumer products. We have performed materials characterization to ensure products and supplied materials/parts meet specifications, to test efficacy and performance, and to compare to competitor’s products. Our analyses have helped our customers develop competitive products. In one example, our team analyzed guitar strings allowing an instrument maker to correlate materials composition properties with sound quality. We have applied our composition analysis, thermal analysis, electrochemical testing, and microscopy to a wide range of personal and household goods, ranging from gemstones for use in jewelry to plastic cups.

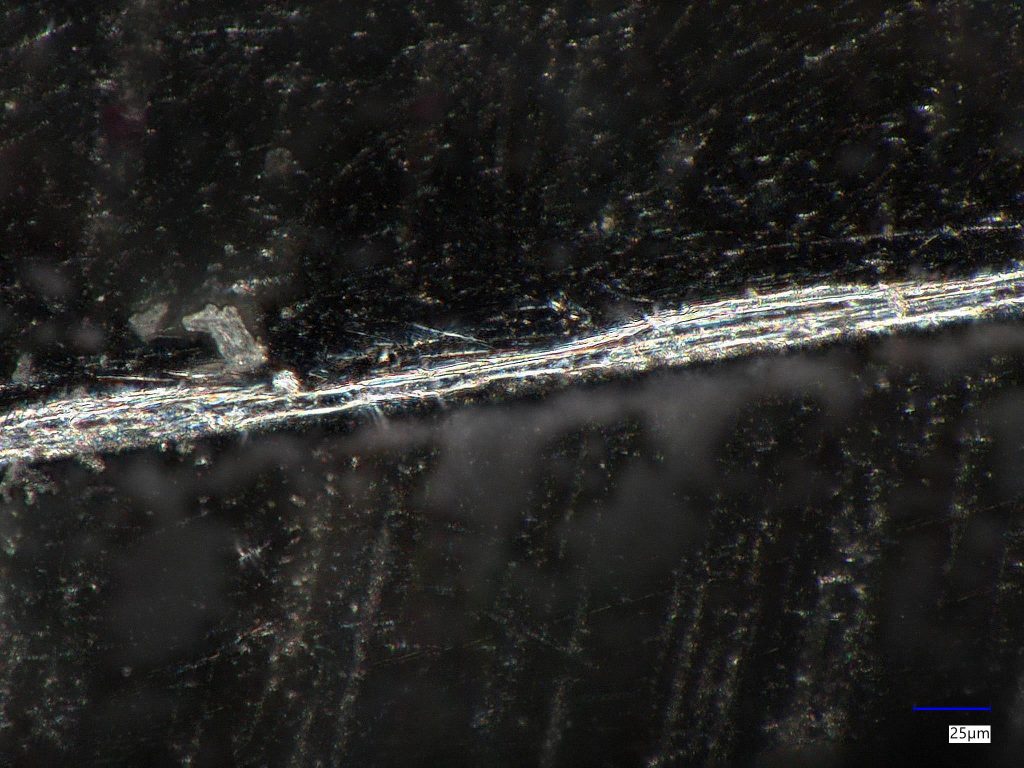

We have also worked with our customers to determine the cause of product defects. Examples of such defects include adhesive bonding issues, tarnishing and corrosion, and materials compositions issues. When a sporting goods product made of a composite material failed to meet stiffness requirements, we were asked to determine the fiberglass content of good and bad materials. Unlike two laboratories that had done the same analysis without finding a cause for failure, our observations of the material and experience led us to broaden our investigation of the problem beyond just measuring the filler weight to identifying the root cause.

Our consumer goods customers include:

Automotive & Boating:

| Advanced Auto Trends Inc. | Haibeck Automotive Technology |

| AMPORTS | Herrington Harbour South |

| Anatech | Honda of America Manufacturing |

| Arrow Dynamics | Honda R&D Americas |

| Arthur H. Terry & Co., LLC | HotStart, Inc. |

| AY Manufacturing, Ltd. | II Stanley Company |

| Beclawat Manufacturing Inc. | Inteva Products |

| Bendix Commercial Vehicle Systems LLC | JE Pistons |

| Bowles Fluidics Corporation | Laird Technologies |

| Cadillac Products Automotive Company | Magna Donnelly |

| Carlisle Industrial Brake and Friction | Nissin Brake Georgia Inc. |

| CTS Corporation | Patrick Power Products |

| Dettling Yacht Company | Performance Friction Corp. |

| Eaton Corporation | Pilkington North America |

| EControls, LLC | Rolls-Royce Crosspointe, LLC |

| EFTEC North America LLC | Romarine |

| Flex-N-Gate | RV6 Performance |

| Fras-le North America | SLW Automotive |

| General Motors Corporation | Specialty Coatings |

| Gentex Corporation | Superior Industries International |

| Guardian Science & Tech | Tri-Con Industries, Ltd. |

Food and Beverage:

| Advanced BioNutrition | Malgor & Co., Inc. |

| AN-FO Manufacturing Co. | Mighty Leaf Tea Company |

| Atlantic Equipment Specialists | Monsanto |

| Berry Plastics | Mighty Leaf Tea |

| Blount Fine Foods Corp. | Natural Waters of Viti Ltd. |

| Corazonas Foods | Novel Ingredient Services |

| Diamond Automation | Perrigo |

| Fieldale Farms | Sorrento Lactalis |

| Food and Drug Administration (FDA) | TIC Gums |

| Grace Materials Technologies | Wausaw Paper |

| Harkness International | Winpak Portion Packaging Inc. |

| Hot Pepper Wax |

Personal and Household Goods:

| Baby Convenience | Oasis |

| BetterThanDiamond | Ohio Art Company |

| Bowles Fluidics Corp. | Polk’s Hobby |

| Coty, Inc. | ProStrong |

| Escalade Sports | Rochester Precision Optics LLC |

| Essilor of America | Rosecroft Raceway |

| Firecut Diamonds | SOLO |

| Haworth | Sun Products |

| hwi METRO | Sweetheart Cup |

| Lifoam Industries | Textileather, a Molex Company |

| Meyco Products | Urban Canteen |

| Numismatic Guaranty | Web Industries, Inc. |