We work with many different resource materials including:

Metals and Alloys

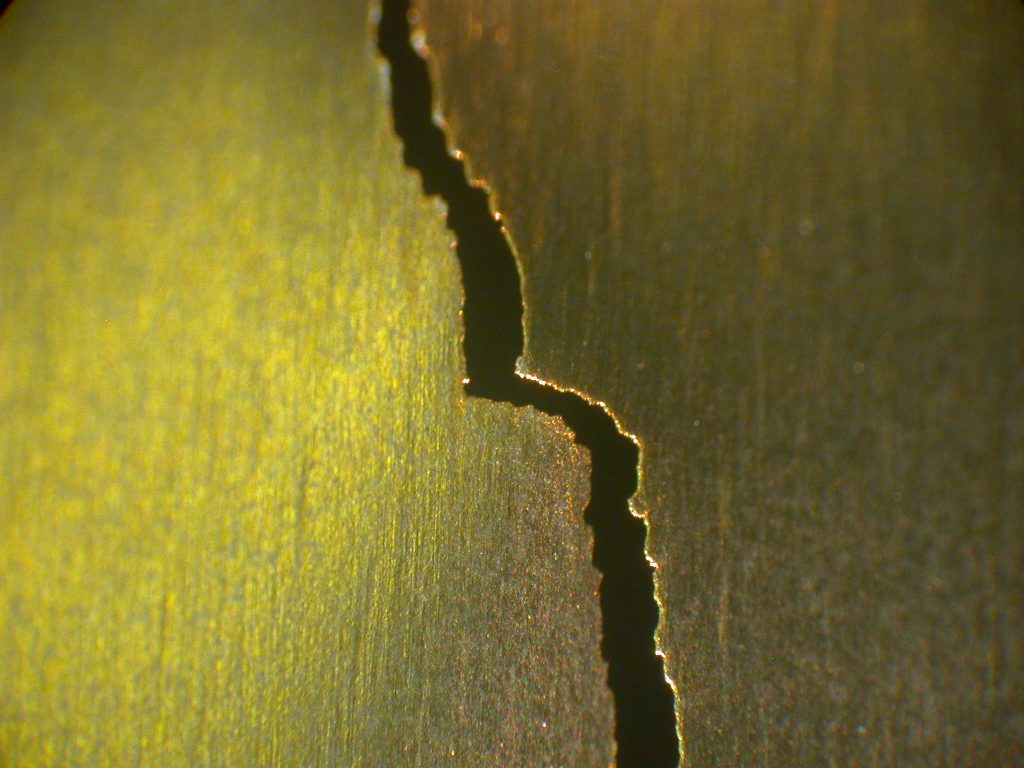

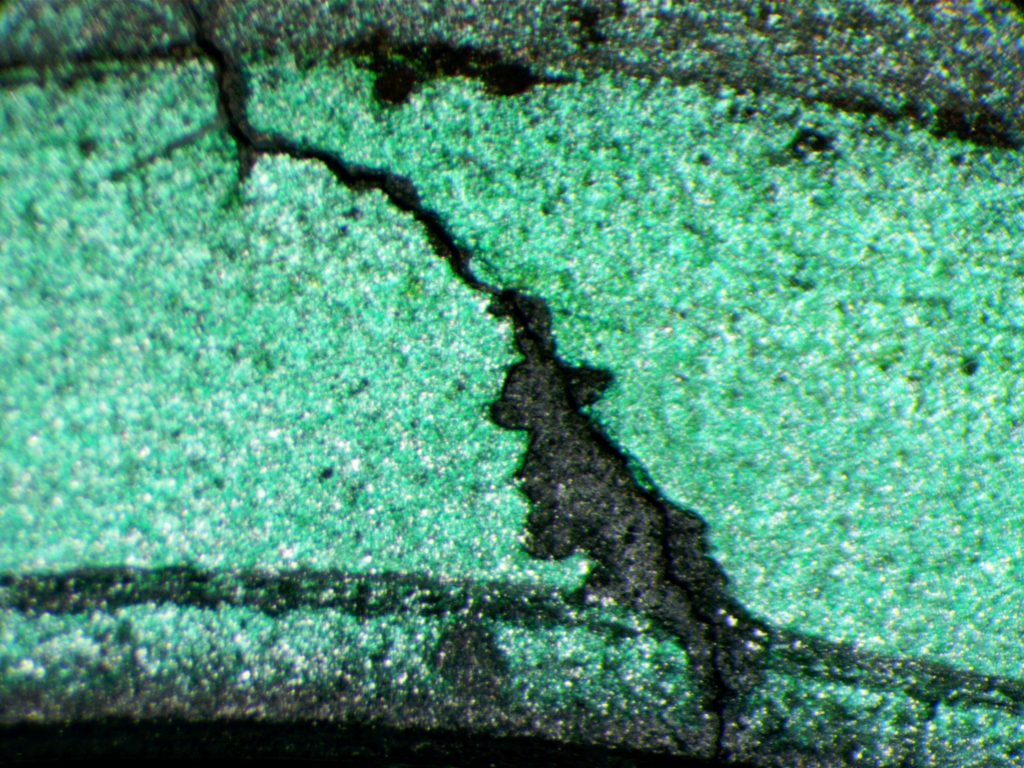

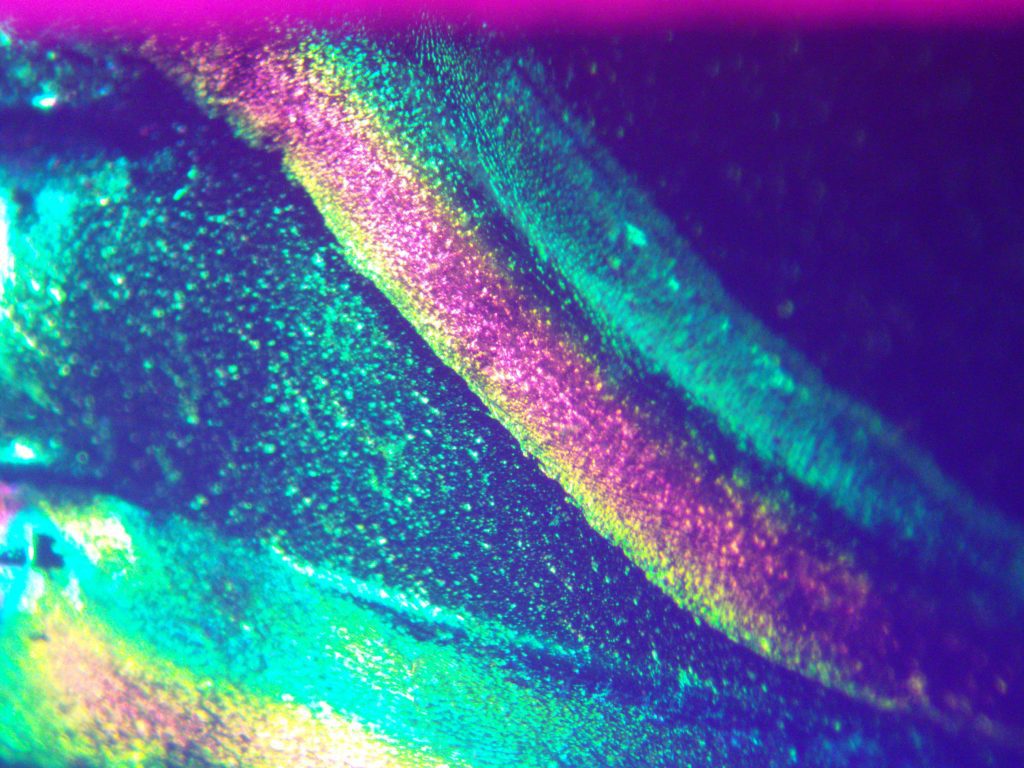

Anderson Materials Evaluation, Inc. has examined the cleanliness of sheet metal, the passivation of metal surfaces, anodized, galvanized, galvanannealed, and painted metal surfaces. We have measured the melting temperature of low melting temperature metals such as solders, the energy of precipitation reactions in aluminum alloys, the Curie temperature of magnetic phase transitions, the exothermic energy of intermetallic phase formation in small domain or thin layer Ni – Al and Ti – Al composite metal systems, and the thermal expansion properties of metal alloys such as super invar, invar, stainless steels, aluminum alloys, brass alloys, and metal contacts in electronics. We have measured the corrosion rates and pitting potentials of many metals in many liquid environments. We provide sensitization tests for stainless steel alloys. We perform numerous metallographic and failure analyses of metal alloys. AME investigates adhesive bonding and coating problems on metal surfaces by identifying contamination problems and surface treatment problems on the surfaces. We have rigorously determined when failures of clear-coated and base paint coated metal coils subjected to MEK double-rub tests occurred due to inadequate curing. We have identified surface chemistries affecting the flow of metal particles, fire works colorant particles, and of chaff particles. We have examined phase changes in Nitinol. We verify whether supplied metal alloys are as-specified. AME provides composition analysis as a function of depth of multi-layered metal thin film structures.

Minerals and Mining Materials

AME has characterized mined minerals including clay particles such as bentonite, diatomaceous earth, sand materials, gypsum, talc, abrasives, complex silicates, calcium and magnesium carbonates, glass-making minerals, gemstones, and iron ores, coltan and other valuable metal ores. We have analyzed high purity antimony, zirconium, and iron oxides. We have also determined problems relating to wear in rock grinding equipment.

Paper and Packaging

AME has examined specialized papers used in medical diagnostics materials and other specialized and coated paper products. We have examined paper and plastic materials with additional polymer coatings to reduce water and gas permeability. We have addressed printing problems on paper and plastic owing to surface cleanliness, surface coatings and treatments, and wear issues. AME has identified the cause of problems in sealing paper and plastic packages. We have identified plastic packaging materials for recycling purposes. We identified how differences in polymer crystallinity affected ultrasonic sealing, latent energy of melting, or coefficient of thermal expansion properties. We measure the glass transition temperature of plastics used in packaging, including electronic integrated circuit packaging. We have addressed many problems in plastic packaging for medical and dental devices, diagnostic materials, and pharmaceuticals.

Please contact us with your resource material concerns and our team of highly trained Ph.D. scientists will work with you to find solutions.