Read about the analysis techniques we have at our fingertips to help with your paper and packaging materials analysis needs. Wood itself is included in the following discussion. For packaging materials, also see: Plastic / Polymer Testing & Analysis and Electronics / Semiconductor Materials Analysis

Metallographic / Optical Microscopy / SEM for Paper and Packaging Materials Analysis:

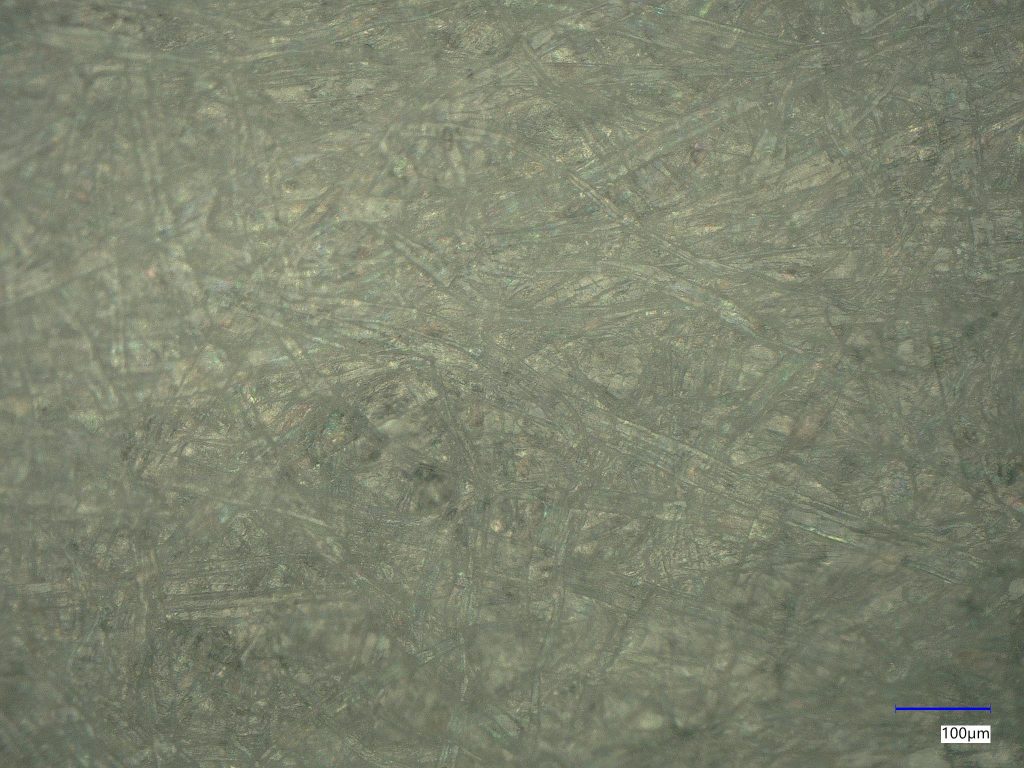

- Examine surface texture and gloss

- Fiber thickness, orientation, and density

- Detect the presence of foreign particles

- Examine particles added to brighten the paper

- Check for evidence of an organic or polymer coating

- Examine whether an organic or inorganic material is distributed evenly on the paper

- Measure reflectivity as a function of UV and visible light wavelength

- Measure color properties

- Measure gloss as a function of wavelength or more conventionally with separate gloss meter

- Determine the surface elemental composition and surface chemistry

- Identify the causes for printing and collating problems

- Identify the causes for adhesive bonding problems

- Determine the chemical nature of stains or aging and degradation

- Analyze surface coatings and surface treatments

- Analyze materials adsorbed onto the surface (adsorbants)

- Identify surface brightening particles

- Identify and measure surface contaminants

- Identify lubricants and anti-static coating materials

- Analyze filler inorganic particles after combustion of paper/polymer

FTIR Analysis for Paper and Packaging Materials Analysis:

- Fingerprint matching of papers

- Determine if an organic coating or binder is present

- Identify an organic coating, whether for printing, tack, water-retardation, separation, or adhesive purposes

- Identify an ink or a brightening agent coating on paper

- Identify the fibers of high performance papers which may be glass, alumina, ceramic, asbestos, carbon, vinylon, aramid, fluorocarbon, polyester, polyolefin, or cellulosic fibers

- Identify lubricants or waxes as surface coatings and treatments

GC-MS or Gas Chromatography – Mass Spectroscopy

- Identify organic coating chemistry

- Identify and measure organic residues left on wipes or in filter paper

- Identify component organic chemicals in inks

- Identify component organic chemicals in plastic packaging materials such as foams and elastomers

- Identify additives in adhesives

- Identify fragrance chemicals in wood

- Identify some preservatives in wood

Wavelength-Dispersive XRF for Paper and Packaging Materials Analysis:

- Quantitatively measure carbon and nitrogen concentrations

- Quantitatively measure the concentrations of elements carbon, nitrogen, and fluorine and heavier

- Detect heavy elements with concentrations as low as 10 ppm or less

- Detect fire-retardant additives

- Measure and identify some preservatives in wood

- Identify heavier elements beneath thin polymer surface layers, including metallized layers

- Measure the sulfur content of paper

- Detect elements used for paper coatings

- Measure the degree of crystallinity of a polymer used in packaging

- Identify inorganic particles used to coat paper

- Measure surface roughness and waviness

- Surface integrity

- Surface texture

Thermogravimetric Analysis or TGA:

- Measure water content

- Measure weight of coating

- Measure outgassing as a function of temperature

- Measure drying time

- Measure weight loss due to high temperature to characterize paper heat resistance

- Measure inorganic solids content, such as weight of calcium carbonate, Kaolin clay, titanium dioxide, silica, etc.

- Concentrate inorganic solid particles for XPS analysis by burning paper in air or scissioning polymers in high temperature nitrogen

- Distinguish starch and latex copolymer binders, where latex is usually combined with styrene, butadiene, acrylic, and vinyl acetate monomers

Differential Scanning Calorimetry or DSC for Paper and Packaging Materials Analysis:

- Measure glass transition temperature of organic coating

- Measure melting temperature and heat of fusion of organic coating

- Characterize paper heat resistance and aging

- Measure exothermal heat of combustion

- Distinguish starch and latex copolymer binders

- Measure thermal expansion or CTE

- Measure glass transition temperature of organic coating

- Measure melting temperature of an organic coating

- Measure crystallization melting temperature & determine amount of crystallization

- Measure outgassing as a function of temperature

- Measure desorbed vapors

- Measure combustion products

ASTM Test Methods for for Paper and Packaging Materials Analysis

- ASTM E96: Standard Test Methods for Water Vapor Transmission of Materials

Case Histories

Wood Preservative Analysis of Disintegrating Wood

Contact us today with your paper and/or packaging materials concerns and we will discuss how our vast array of analysis techniques and years of experience can help find solutions to your unique needs.