Our materials analysis laboratory has considerable ceramic materials analysis experience.

Ceramic materials are formed by processing inorganic particles under high pressure and at high temperature in most cases. The surface chemistry of these particles plays a major role in the sintering of particles. Binding materials that provide a more complete bonding of particles may be added. Brittle ceramic materials tend to fracture along the interfaces of the original particles sintered together and x-ray photoelectron spectroscopy (XPS) surface analysis can be used to investigate the properties of the materials along this extremely thin fracture surface. Analysis by EDX will provide a more nearly bulk material analysis.

In some cases, ceramic layers are formed from a paste of inorganic particles in an organic binder, to which heat is applied. Ceramic materials may be deposited by a sputtering process or by a chemical vapor deposition (CVD) process. Anderson Materials Evaluation has many ways to characterize these materials for their composition and physical properties. We have many means to identify problems and to suggest process or materials ingredient changes to our clients. Some examples of ceramic materials analysis follow:

TMA:

- Measure thermal expansion rates (often called CTE) as a function of temperature

- Measure shrinkage as a function of firing a green ceramic to 800° C

- Measure any phase transition temperatures below 800° C

TGA:

- Measure the change of weight as a function of temperature to determine the rate of binder loss with temperature to 1000ºC

- Measure outgassing of ceramic upon heating

- Measure the weight of absorbed water or other fluid due to porosity upon heating to 1000ºC

SEM, Optical Microscopy, and Keyence 3D Microscopy:

- Imaging of fracture surfaces to determine particle sizes and see residues of organic binders

- Cross section analysis to evaluate cracks and voids

- Examine surfaces for cracks and voids

- Detect stains to identify their cause with EDX or XPS

- Measure surface profiles and surface roughness

- Determine the elemental or oxide composition of the ceramic

- Detect very low concentration impurities in the ceramic, especially heavy metals

- Heavier elements can be detected to depths of up to about 2 millimeters from the surface

Laser-Induced Breakdown Spectroscopy (LIBS) :

- Quickly determine the major composition of a ceramic material

- Determine ceramic compositions when areas are too small for XRF, without charging problems that may occur doing EDS

- Measures all elements except hydrogen and helium to a depth of about 20 nm

- Argon ion etching allows composition analysis to greater depths

- Analysis of the composition of ceramic precursor powders or particles

- Analysis of surface contamination of fired ceramics

- Check chemistry of binding agents to promote sintering

- Measure water content, impurities, and reacted layers on raw ceramic material particles

- Analysis of fracture surface chemistry to determine binder and pre-sintered particle surface chemistry effects on fracture plane

- Degradation effects upon ceramic such as caused by moisture on boron nitride (BN) or on alumina (Al2O3)

- Precise quantitative chemical phase identifications

- Measure changes in ceramic due to environment, such as leaching of elements, chemical uptake in the voids between poorly sintered particles, and reaction products

- Detect interparticle chemistries that may change insulation or RF response properties of the ceramic

- Determines the crystalline phase of the bulk ceramic

- May determine the crystalline phase of binders between the sintered polycrystalline particles

Energy Dispersive X-ray Analysis (EDX or EDS) :

- Measures elements sodium and heavier semi-quantitatively

- Detects elements carbon, nitrogen, oxygen, and fluorine

- Determine elemental composition to depths of 1 to 2 micrometers

Infrared Spectroscopy (FTIR) Analysis:

- Check the organic binder chemistry of a ceramic paste

- Identify organic contaminants on ceramic or absorbed by it after use

- Identify carbonates, water, phosphates, sulfates, and nitrates in inorganic pre-cursor particles

- Identify outgassing products such as boric acids from boron nitride BN caused by hydration

- Measure water desorbed from pores

- Limited use in identifying and measuring higher mass contaminants adsorbed while in use or storage

Gas Chromatography – Mass Spectroscopy:

- Identify outgassing products such as boric acids from boron nitride BN caused by hydration

- Identify and measure volatile contaminants adsorbed while in use or storage

- Identify and measure solvent leached contaminants, including high mass organic compounds adsorbed during use or storage

ASTM Standards

ASTM C20: Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water

ASTM C773: Standard Test Method for Compressive (Crushing) Strength of Fired Whiteware Materials

Case Histories

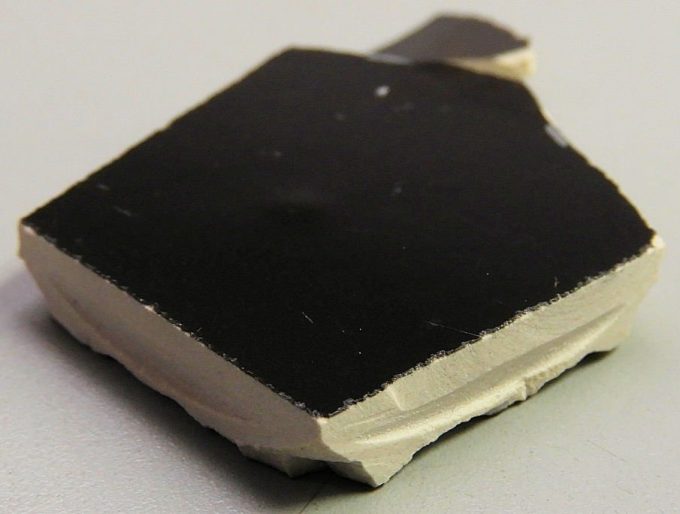

Ceramic Powder Identification on Floor Tile

Cracking and Yellowing Cubic Zirconia Ceramic

Defective Ceramic Floor Tile Glaze

Lead in a Ceramic Dinner Plate – Evaluating the Safety Hazard with XRF and XPS Analysis