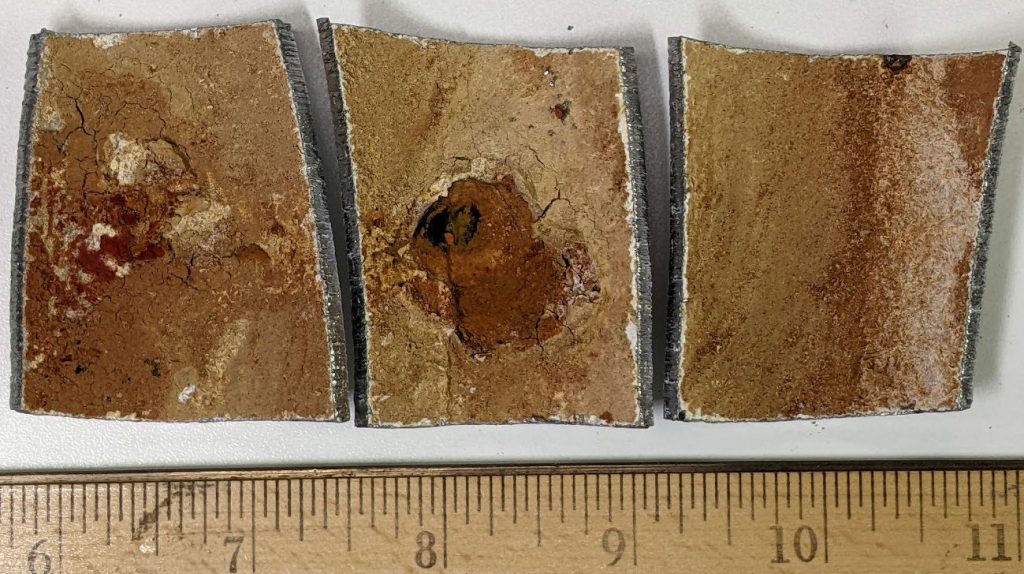

The galvanized steel pipe shown below was analyzed with high resolution 3D optical microscopy using our Keyence 7000N and with its EA 300 laser-induced breakdown spectroscopy (LIBS) for elemental microanalysis to determine the cause of pinhole corrosion. Our investigation concluded that the cause was microbiologically influenced corrosion (MIC).

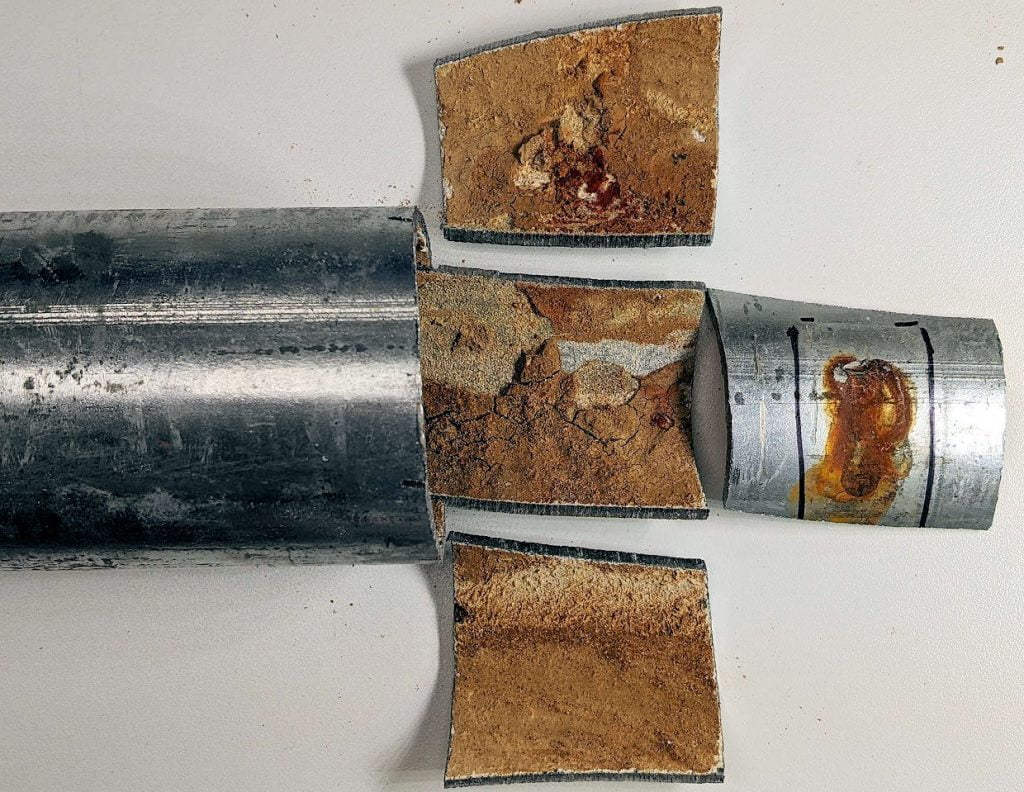

The deepest part of the pit on the inside wall of the galvanized steel pipe is the largely black vertically oriented area on the right side of the above image. Note that there is a hazy translucent line along the bottom edge which suggests the presence of an organic material. However, it turned out that the outside wall pit appeared more likely to provide the cause of the formation of this corrosion pit.

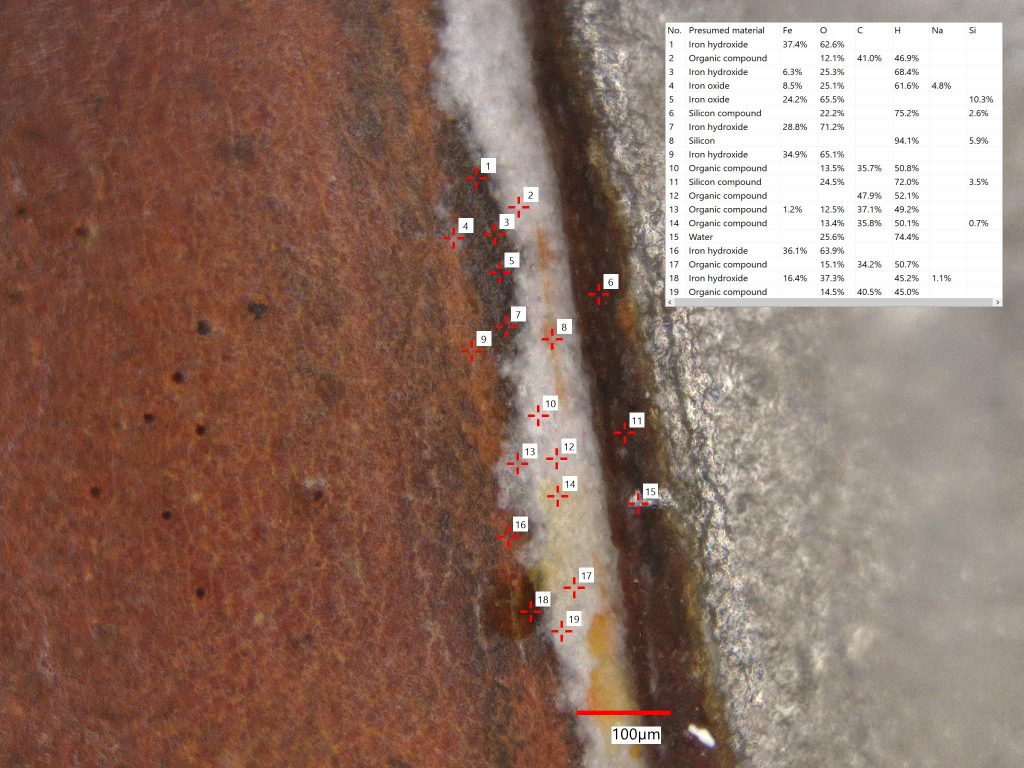

The outside wall pit is above the red scale bar and is oriented upward in the image. The pit interior is a dark brown color and the wide lips around the pit are bare steel. The light material at the far right of the above image is the galvanized coating. Outside of the pit, the white materials are principally zinc oxide. At the edges of the pit, near the bare steel, but on top of a generally blacker material, is a white, somewhat translucent biofilm material.

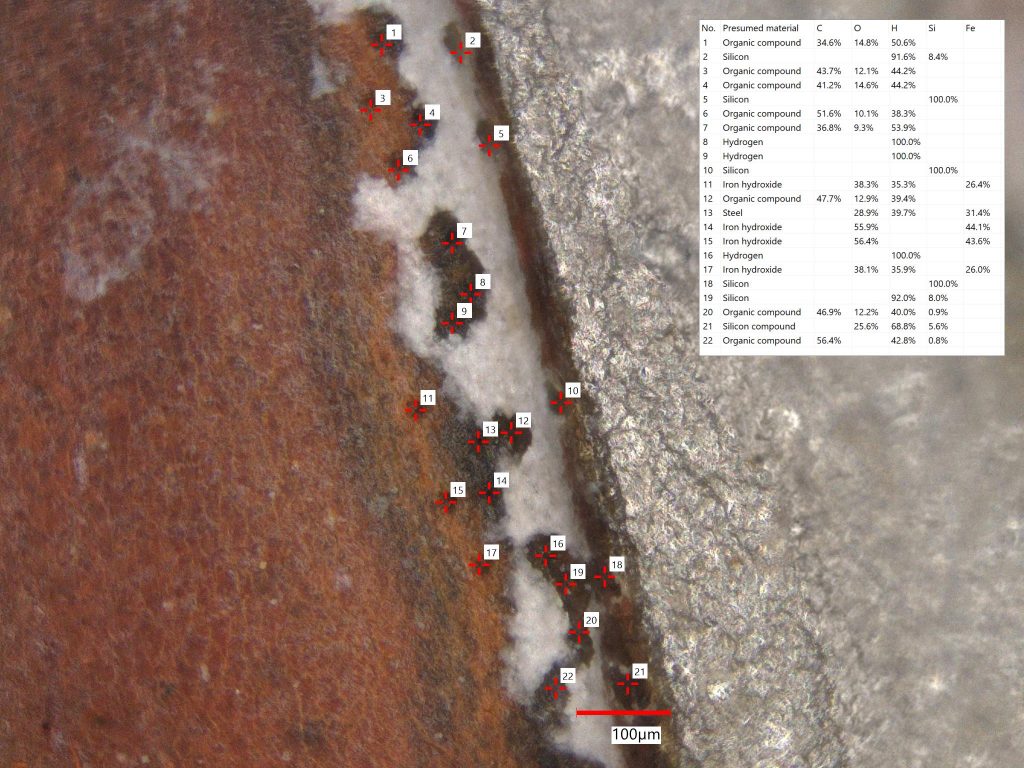

The image above shows the white edge material LIBS analysis results in the embedded table. This material proved to be organic. Some tiny holes in the bottom of the pit in the reddish brown material are where previous LIBS analysis was performed showing that material to be iron oxide and iron hydroxide corrosion products.

The image above is of another area of the biofilm showing the LIBS analysis spots imposed on the post-analysis image. The LIBS has three pulse strengths. The weakest pulse strength was used here and even that weak pulse blew away the fragile organic material 2 or 3 times the expected diameter for the ablation crater for most materials. When the selected analysis spot had been on the white film, the LIBS analysis result was that it was organic material.

A second smaller pit which had not erupted through the pipe was also analyzed. It showed much biofilm on the inner wall of the steel pipe inside the pit.

The conclusion of this investigation into the cause of the pitting corrosion of the indoor sprinkler system galvanized steel pipe was that it was caused by Microbiologically Influenced Corrosion or MIC.

Other Case History examples of corrosion analysis investigations can be found Here.