Below are some of the examples of thin film analysis performed by our lab.

XPS Analysis (10 nm depth, elemental and chemical bond analysis):

- Surface chemistry and film stoichiometry, especially subject to variation for sputtered or CVD films

- Elemental composition as a function of depth, useful to examine multilayer film structures such as anti-reflective coatings, metallization layers on ceramics for brazing, or coatings such as TiN on biomedical devices

- Interface contamination

- Surface hydration measurements

- Failure analysis of delamination problems

- Determine whether film layers have reacted or boundaries are sharp

- Diffusion as a function of temperature in vacuum

- Reaction of discrete film with other layers or with substrate as a function of temperature, such as due to brazing or soldering

- Reaction of film or multilayered film with heating in various gases

- Surface analysis of polymers, but cannot perform ion etching analysis of polymers

FTIR Analysis (1 – 2 micrometer depth, chemical bond analysis):

- Detect and identify thin organic or polymer film on metal or semiconductor surface

- Identify thin organic film used to prevent reactions of a thin film structure with the environment as in corrosion

- Identify plastic or polymer with metallization film

Thin Film Thickness Measurements:

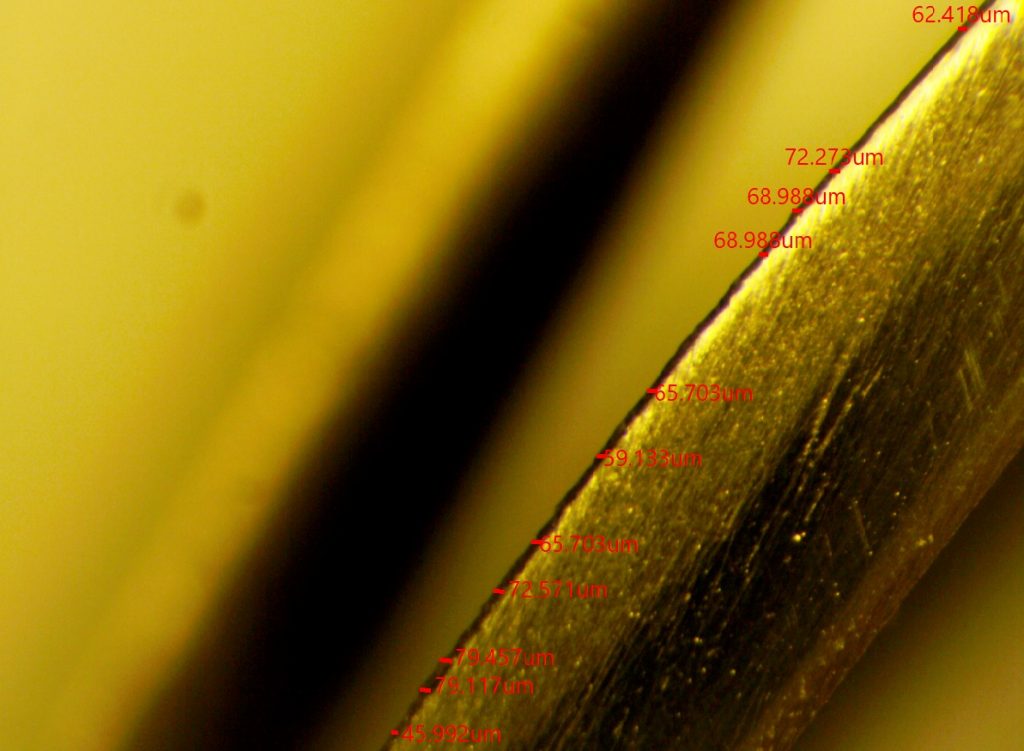

- SEM or metallographic microscopy imaging of cross section

- Depth profile or angle-resolved XPS if very thin

Profilometry or Surface Roughness and Microscopy:

- Measure surface roughness

- 3-dimensional surface topography mapping

- Detection of defects as small as 500 nm

- Measurement of 2D and 3D distances

- Layer thickness measurements

Laser-Induced Breakdown Spectroscopy (LIBS) :

- Quickly determine the major composition of a thin film

- Quickly determine whether a material has such elements as aluminum, calcium, sodium, lead, or boron at elevated concentrations

Reactivity of Thin Film:

- TGA measurement of film weight gain due to reaction with gas as temperature is increased

- TGA testing of oxidation protection offered to substrate material by thin film or test for reactivity at higher temperatures and examine by XPS afterward

- DSC measurement of exothermal heat of reaction due to reaction of film with substrate or with other layers in multilayer structures, such as for intermetallic phase formation

- DSC measurement of endothermal heat of melting or of crystalline phase changes

- DSC measurement of exothermal heat of reaction with heating in a gas

- XPS substrate element diffusion through film to surface in active atmosphere conditions or upon heating

- Multilayer film interlayer reactions by depth profile XPS with exception of polymers

- Thickness measurement

- Grain size and orientation

- Detection of inclusions

- Uniformity

- Observable phases (carbides, intermetallic phases, graphite micro clusters, etc.)

Adhesion Failures:

- Failure analysis of peeled or delaminated thin film for locus of failure and detection of contamination, hydration, reacted layer, or other causes of failure using XPS and FTIR

- Examination with metallographic microscopy or SEM to determine mode and locus of failure