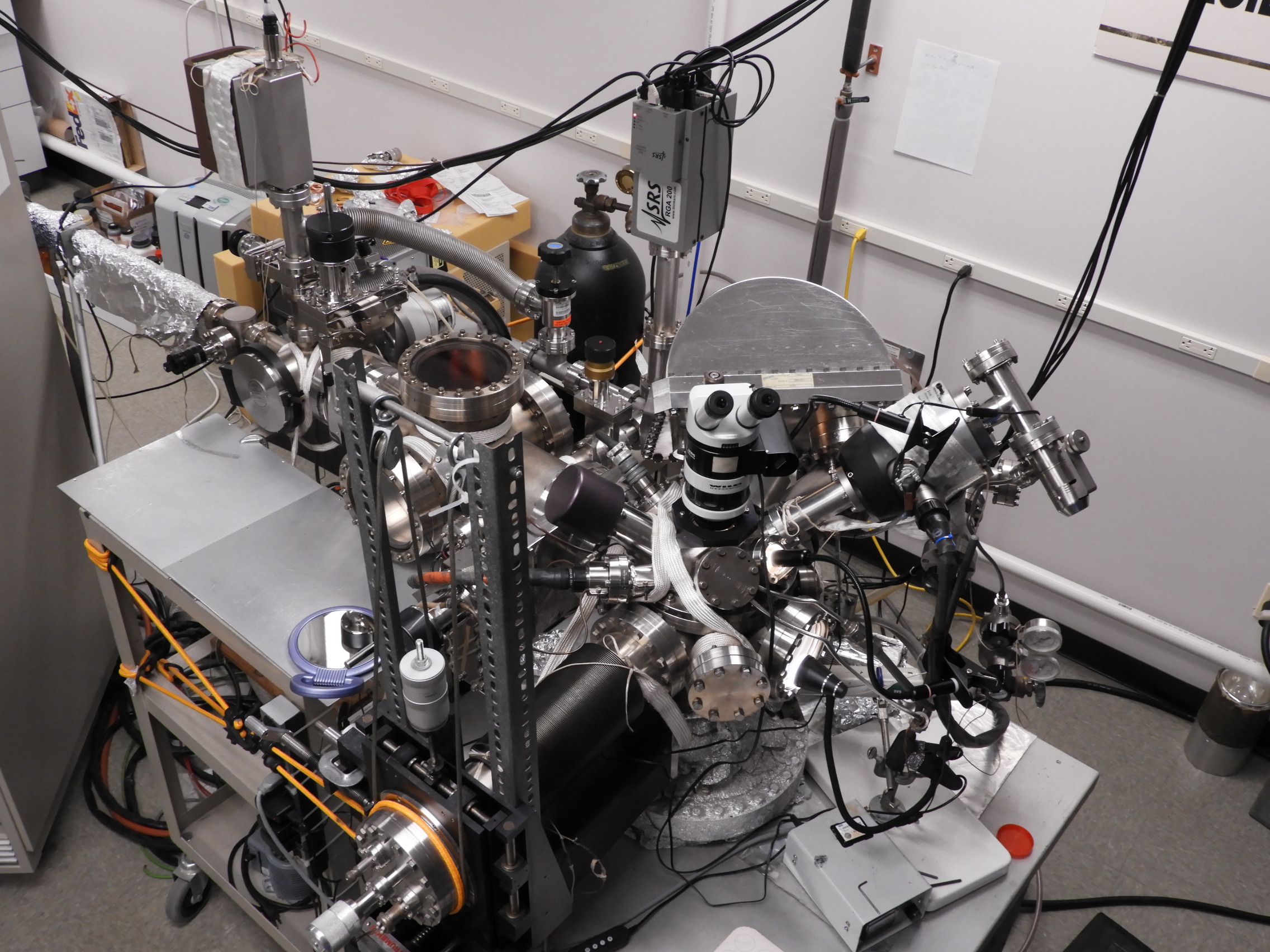

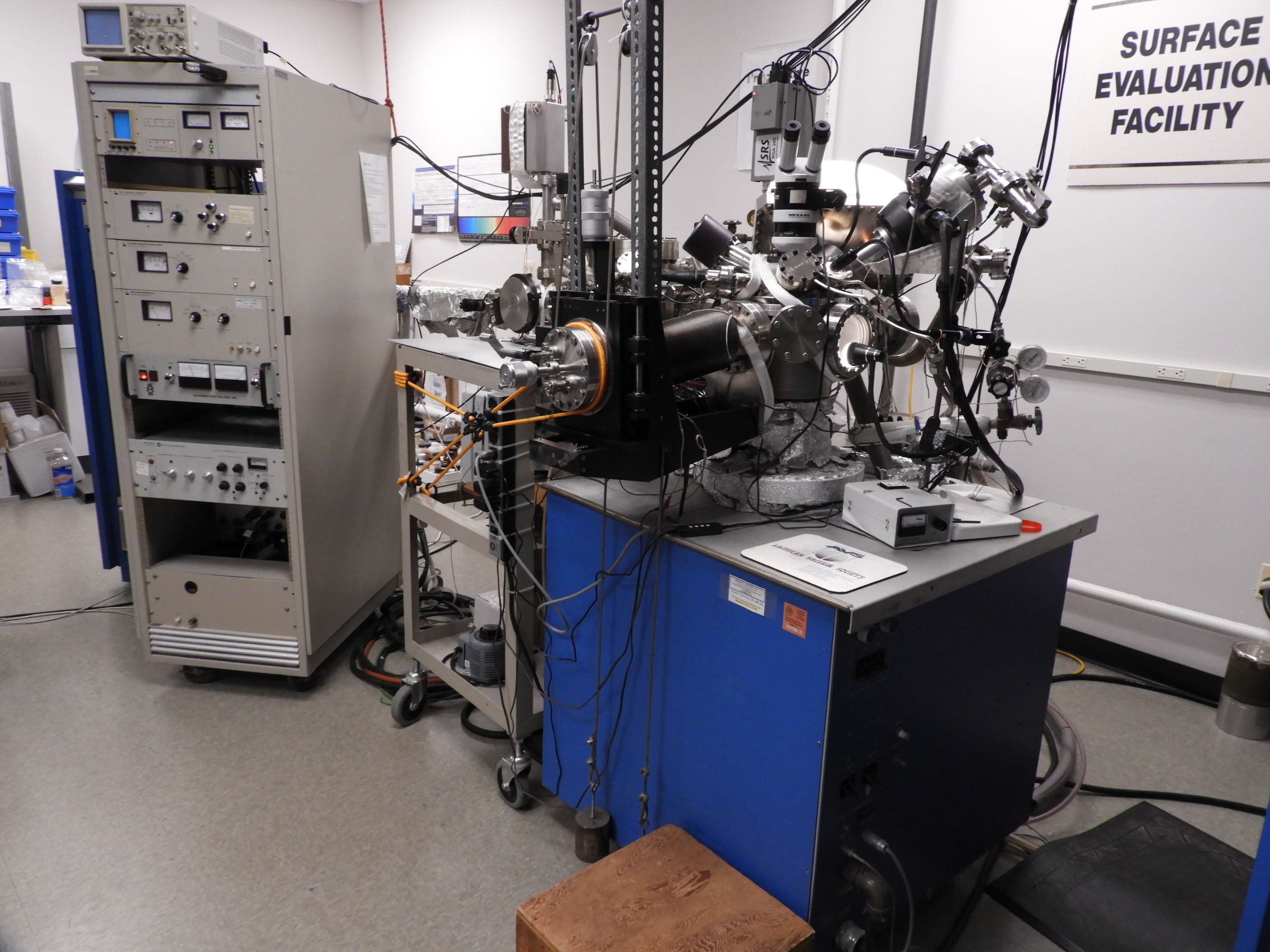

At AME Labs, we specialize in X-ray Photoelectron Spectroscopy (XPS) surface analysis, providing precise insights into solid surface composition. Our advanced techniques also include surface contamination testing, ensuring thorough characterization for diverse industries. Trusted for accurate results, we detect and quantify contaminants, study surface chemistry changes, treatments, corrosion, and adhesive bond failures. Contact Charles R. Anderson, Ph.D., to discuss your surface analysis needs.

XPS Surface Analysis is also known as X-ray Photoelectron Spectroscopy or Electron Spectroscopy for Chemical Analysis – ESCA.

Key Features of XPS Surface Analysis

- Quantitative Elemental Analysis: XPS enables precise elemental analysis for all elements except hydrogen, offering valuable insights into surface composition.

- Surface Sensitivity: With high surface sensitivity, XPS can detect and analyze surface layers down to the outer 20 nm, making it ideal for studying surface treatments, corrosion, and adhesive bond failures.

- Chemical Composition Information: XPS provides detailed chemical composition information, helping to identify chemical species and surface chemistry changes.

XPS Surface Analysis Applications

XPS surface analysis can be applied in numerous ways. Some examples are listed below:

General Material Applications

- Surface Contamination Detection: Identifying and quantifying surface contaminants.

- Adhesive Bond Failure Analysis: Investigating causes such as contamination or chemical interactions.

- Corrosion and Material Degradation Identification: Early detection of corrosion and degradation factors.

- Material Composition Characterization: Analyzing surface and near-surface compositions.

- Coating Composition Analysis: Determining chemical stoichiometry of coatings.

- Joining Process Problem Resolution: Addressing issues in soldering, brazing, and welding.

- Polymer Sealing Investigations: Studying issues related to polymer seals.

- Intergranular Failure Cause Identification: Understanding failures at grain boundaries.

- Film Deposition and Particle Reaction Analysis: Assessing film and particle interactions.

- Surface Chemistry Changes: Due to leaching, heating, or radiation.

- Surface Phase Identification: Characterizing unique surface phases in materials.

- Interface Reactions and Interdiffusion: Studying reactions at material interfaces.

- Surface Cleaning Process Evaluation: Assessing the effectiveness of cleaning methods.

- Surface Modification Characterization: Studying chemically treated surfaces.

Specific Material Applications

- Silicone Contamination Evaluation: Highly sensitive detection using XPS analysis.

- Medical Device and Prostheses Analysis: Identifying wear, corrosion, and bonding issues.

- Semiconductor Material Problem Investigation: Analyzing issues in semiconductor device fabrication.

- Nanomaterial Surface and Interface Characterization: Studying properties of nanoscale materials.

- Metal Oxide Composition Analysis: Assessing metal oxide compositions with depth.

- Optical Coating Structure Characterization: Analyzing multilayer optical coatings.

- Hard Disk Drive Surface Characterization: Understanding properties of hard disk surfaces.

- Thin Film Delamination Investigation: Studying issues related to thin film layers.

- Environmental Media Characterization: Analyzing scrubbing and adsorbing materials.

- Protective Coating Problem Identification: Addressing issues with protective coatings.

- Filler Material Identification: Analyzing filler materials in plastics and composites.

- Composite Material Failure Analysis: Identifying adhesive failures and interface issues.

- Mineral and Glass Bulk Chemistry Determination: Assessing bulk compositions of minerals and glasses.

- Corrosion and Wear Deposit Identification: Analyzing deposits on medical implants.

- Gemstone Chemistry Characterization: Identifying chemical compositions of gemstones.

These succinct descriptions provide insight into the diverse applications of XPS surface analysis across various industries and material types.

Learn More About XPS Surface Analysis

For a deeper understanding of XPS surface analysis and its applications, please visit our dedicated page on XPS Analysis – An In-Depth Look. Accordingly, explore our methodologies, applications, and case studies to discover how XPS can provide valuable insights for your projects.

Contact Us

For inquiries regarding XPS surface analysis and surface contamination testing services, contact Charles R. Anderson, Ph.D., at canderson@andersonmaterials.com.