At Anderson Materials Evaluation, we utilize many techniques to analyze surface & interface contamination and cleanliness.

X-ray Photoelectron Spectroscopy or XPS or ESCA:

- Quantitative elemental composition of surface contamination

- Surface contamination chemistry with chemical phase identification

- Extremely high sensitivity with an analysis depth of 10 nm and sensitivity for less than 0.1 monatomic layer

- Verification of surface cleanliness

- Measure silicone surface concentration and relative chain length to determine effect in weakening adhesive bonding to a surface or interface, sealant integrity, wetting problems, or as a source of silicone contamination

- Provide silicone and fluorocarbon contamination detection test kits to be examined by XPS for facility and oven contamination evaluations

- Surface chemistry changes caused by cleaning agents, both improvements and residues left

- Ion sputter gun removal of surface contamination to judge its thickness

- Quantitative elemental and chemical phase identification of interfacial contamination after adhesive failure, peel, or pull test

- Interphase chemistry of interfaces with adhesive bonding – adhesives often have different compositions near interfaces

- Depth profile through thin layers at a surface for elemental analysis as a function of depth

- Analyze residues left after evaporating water or other solvents

- Identify plasticizers, fire retardants, and cross-linking agents in polymers or plastics that migrate to surfaces and interfaces

- Examine surfaces after anodization and etching processes to determine if the surfaces were properly cleaned

FTIR or Infrared Spectroscopy for Surface Contamination:

- Identification of organic functional groups and some inorganic functional groups in thicker contaminant layers using ATR or specular reflectance for greater surface sensitivity

- Bulk or near-surface (1 -2 micrometers deep) organic material composition for comparison to surface organic composition

- Identify plasticizer or fire-retardant segregated to the surface of a plastic/polymer material

GC-MS or Gas Chromatography – Mass Spectroscopy

- Wipe surfaces with swabs and remove and analyze the contaminants from the swab for high-sensitivity GC-MS analysis at the ppb concentration level.

- Rinse a surface with a solvent and analyze the rinse solvent to find what was on the surface.

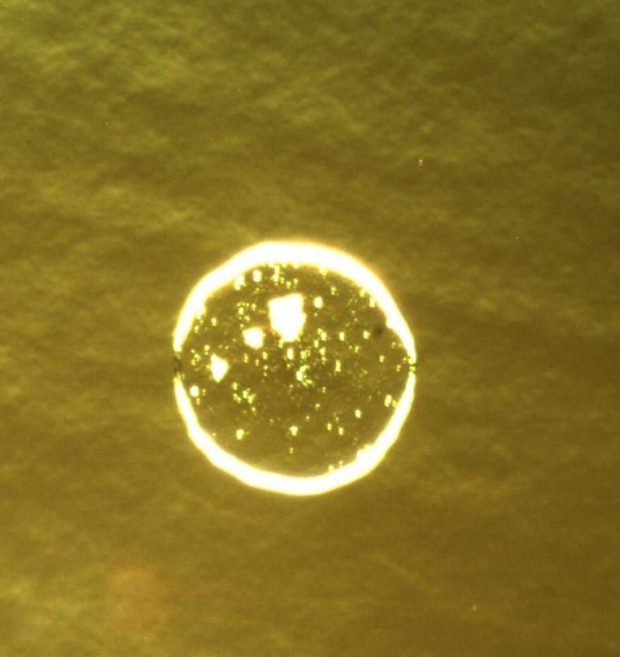

Microscopic Examinations for Surface Contamination:

- SEM with digital imaging to reveal surface inclusions and surface deposits

- Inspection microscope, digital imaging

- Metallographic microscope, digital imaging, Nomarski phase contrast

Profilometry or Surface Roughness and Microscopy:

- Measure surface roughness

- 3-dimensional surface topography mapping

- Detection of defects as small as 500 nm

- Measurement of 2D and 3D distances

- Layer thickness measurements

Laser-Induced Breakdown Spectroscopy (LIBS) :

- Quickly determine the major composition of a material

- Quickly determine whether a material has such elements as aluminum, calcium, sodium, lead, or boron at elevated concentrations

Effect of interfacial contamination on adhesion to the interface using pull tests.

Surface cleaning technique evaluations:

- CO2 snow jet cleaning, in-house capability, but learn more about CO2 snow jet cleaning at Applied Surface Technologies

- Solvent-based cleaning

- Check cleaning effectiveness with above analytical capabilities

- Determine changes in surface chemistry of plastics caused by plasma cleaning

Corrosion Testing for Surface Contamination:

- Identify corrosion products and causes.

Applications:

- Electronics contamination

- Packaging materials contamination

- Medical device contamination

- Composite materials fibers and particulates contamination affecting matrix bonding

- Adhesive bonding preparation and cause of bonding failures

- Corrosion due to contamination

Case Histories

Solving a Polymer Sealing Problem with XPS Analysis

Silicone Detection on the Surface of an Acrylic Adhesive/Polyimide Tape