Welcome to Anderson Materials Evaluation, your premier destination for comprehensive metal testing and analysis services. Our dedicated team of experts utilizes state-of-the-art techniques to address a wide range of metal analysis needs. Explore our key capabilities:

XRF or X-ray Fluorescence Spectroscopy:

- Identify the metal alloy

- Identify the corrosion products of a metal

- Detect and measure heavy metals

XPS or ESCA Surface Analysis:

- Detect and identify surface contaminants.

- Analyze surface oxide chemistry.

- Identify corrosion products.

- Determine the chemistry of surface treatments or stains.

- Measure elemental composition variations.

- Investigate causes of adhesive bond failures.

X-ray Diffraction (XRD) Analysis:

- Identify metal alloy crystalline phases.

- Determine surface oxidation and treatment products.

- Quantify intermetallic phases.

- Analyze quench rates and phase transformations.

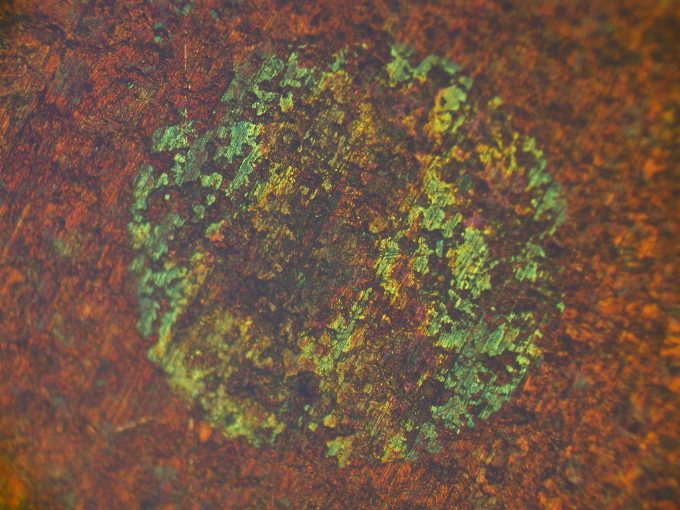

Corrosion Testing:

- Determine causes of corrosion.

- Assess pitting and crevice corrosion.

- Analyze galvanic corrosion between metals.

- Investigate stress corrosion cracking.

- Identify Microbially Induced Corrosion (MIC)

FTIR or Infrared Spectroscopy Analysis for Metals Testing:

- Identify organic coatings and contaminants.

- Analyze layers such as carbonate and sulfate on metal surfaces.

- Address packaging and printing issues.

DSC, TGA, and TMA Analysis for Metals:

- Determine alloy melting points and heat of fusion.

- Measure thermal expansion and phase change temperatures.

- Analyze precipitation reactions and gas reactions with metals.

- Measure the energy of intermetallic formation

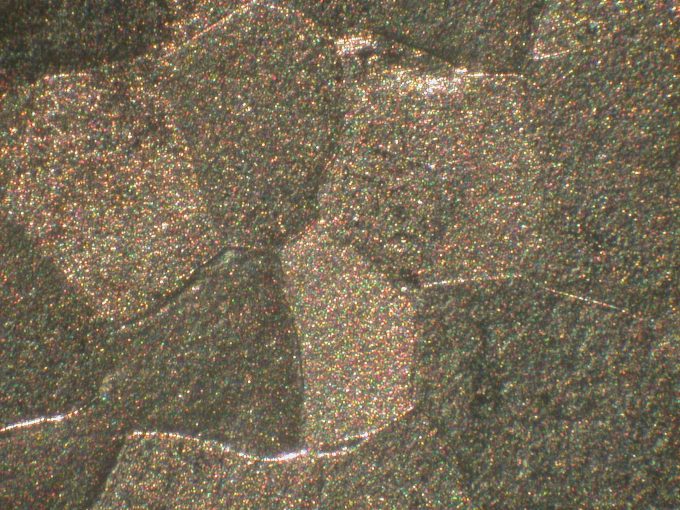

SEM and Metallographic Analysis:

- Image surface morphology and fractures.

- Examine grain sizes, phase distributions, and oxide structures.

- Investigate defects in solder and braze joints.

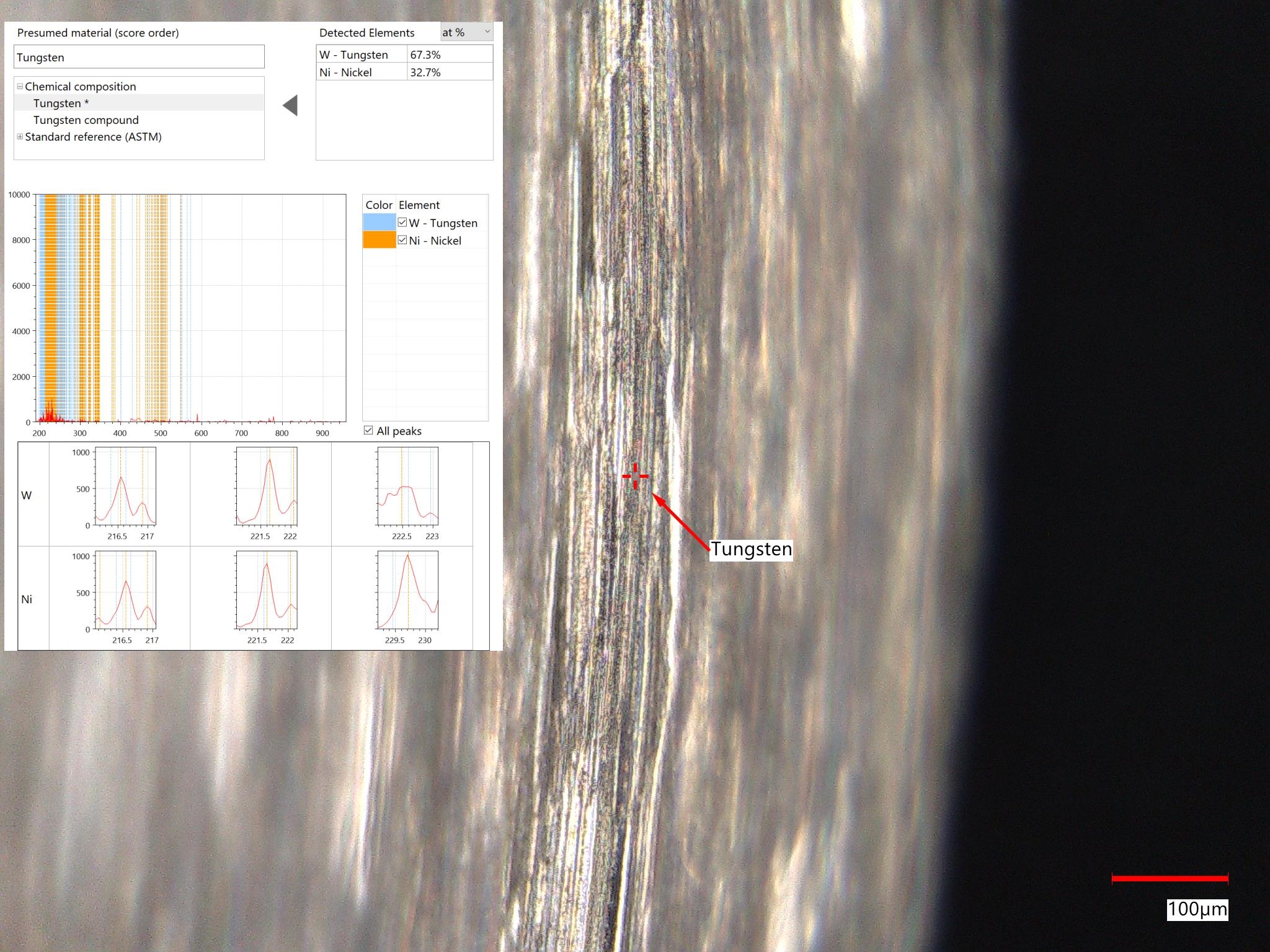

Keyence Microscopy with LIBS Elemental Analysis for Surface Measurements of Metals:

- Image surface morphology and fractures.

- Measure surface roughness and step heights.

- Analyze surface profiles.

- Provide chemical phase information.

- Analyze particle and grain sizes.

Electrical Conductivity Measurements:

- Assess electrical properties of thin metal samples such as resistivity, carrier concentration, and mobility.

Cross Section Analysis:

- Determine cracking modes

- Determine inclusion content

- Examine for voids

- Examine structures for design integrity

Other Property Measurements:

- Measure yield strength, elongation at failure, elasticity, and flexural properties

- Hardness measurement

- Density measurement

- Contact angle measurements

Contact Us

Explore further details on each capability through our dedicated pages or our more detailed metal analysis page here. Contact us today to discuss your specific metal testing and analysis requirements. Our team is ready to deliver tailored solutions to meet your needs effectively.