Anderson Materials Evaluation often analyzes and characterizes inorganic chemicals. These may be used in a free-standing form, as a mixture with other inorganic materials, to treat other materials, or as filler ingredients in polymer products. Their purity, crystalline or amorphous structure, surface properties, and physical form may be critical to the application. It may be important to measure their degree of hydration overall or just at a surface. It may be important to measure the bulk or the surface impurities. Sometimes we examine them to see what the affects of aging or environment are on them. The surface chemistry of an otherwise pure inorganic compound may be very complex. AME can develop an analytical plan to determine complex, quantitative, multi-phase chemistry in an inorganic material.

These inorganic chemicals may be used as fill materials for plastics, paints, sealants, adhesives, or other composite materials. They may be the raw materials for glass making or from which ceramic materials are made. They may be water filter materials such as magnesia. It may be a food additive such as silica, calcium carbonate, sodium metasilicate, sodium metabisulfite, sodium tripolyphosphate, or monocalcium phosphate. They may be additive ingredients for concrete, mortar, grout, plaster, or dry wall. Or they may be a component of a chemical separation column or of a chemical sensor. The material may be a component of a corrosion resistant primer coating or drying agent. It may also be a fire retardant such as aluminum trihydrate or antimony oxide.

- Quantitatively determine the elemental composition for elements sodium and heavier

- Depth of detection ranges from a couple micrometers to 2 mm depending upon matrix material and the characteristic x-ray emission energy of the element

- Detect very low concentration elements such as heavy metals down to the 10 ppm range

- Carbon and nitrogen concentrations can be measured for polymer sheet materials with inorganic fill particles in the outer micrometer of the material

- Identification of a crystalline material from its diffraction pattern

- Can determine the weight percent of a mix of several crystalline inorganic materials

- Can distinguish different chemical phases of a material with the same chemical formula

- Can detect and measure amorphous impurities or crystalline contaminants

- Quantitative elemental analysis for all elements except hydrogen and helium

- Depth of analysis: 50% of signal from outer 6 nm and 90% of signal from outer 20 nm

- Particle surface chemistry complete with quantitative elemental composition and chemical phase analysis of multiple complex phases

- Differentiate surface chemistry with interior chemistry by analyzing as-received materials compared to freshly ground particles of material, argon ion sputtered material, or material analysis by XRF, XRD, EDS, or by FTIR

- Great sensitivity to a very thin surface chemistry affecting particle bonding in a polymer matrix or agglomeration controlling surface treatments

- Used to determine and measure the degree of surface hydration

- Used to identify fill materials added to polymers following burn-off of the resin by TGA or other means

- When the sample quantity is very limited, it can perform an analysis when XRF does not see enough material or when the layer thickness is to low for LIBS, XRD, or EDS analysis

Thermogravimetry or TGA Analysis:

- Determine decomposition temperature and measure the weight loss as a function of temperature

- Measure the weight loss of water from hydrated materials

- Measure the weight of carbon dioxide loss from a carbonate

- Impurity detection and measurement either because the impurity decomposes or because the impurity does not decompose in the temperature range the main inorganic chemical does

- Determine the composition of some thermally decomposable materials such as the amount of silver carbonate in a silver oxide

- Measure the weight gain of a material in a given gas atmosphere as a function of temperature, such as oxide formation in an oxygen or air atmosphere

- Measure the oxygen-deficiency in an oxide by its further weight gain in an oxygen atmosphere held at a sufficiently elevated temperature

Differential Scanning Calorimetry or DSC Analysis:

- Determine melting temperature and heat of fusion

- Determine energy and temperature of reaction between an inorganic material and another material

- Impurity detection and measurement by measuring the latent heat of melting or looking for an internal reaction upon heating

- Measure energy to desorb water or to decompose

- Measure temperature of a phase transition

Thermomechanical or TMA Analysis:

- Determine CTE or thermal expansion of materials in plate or cylindrical forms

- Determine thermal expansion of a powder inside a cylindrical holder

- Determine temperature of a phase change

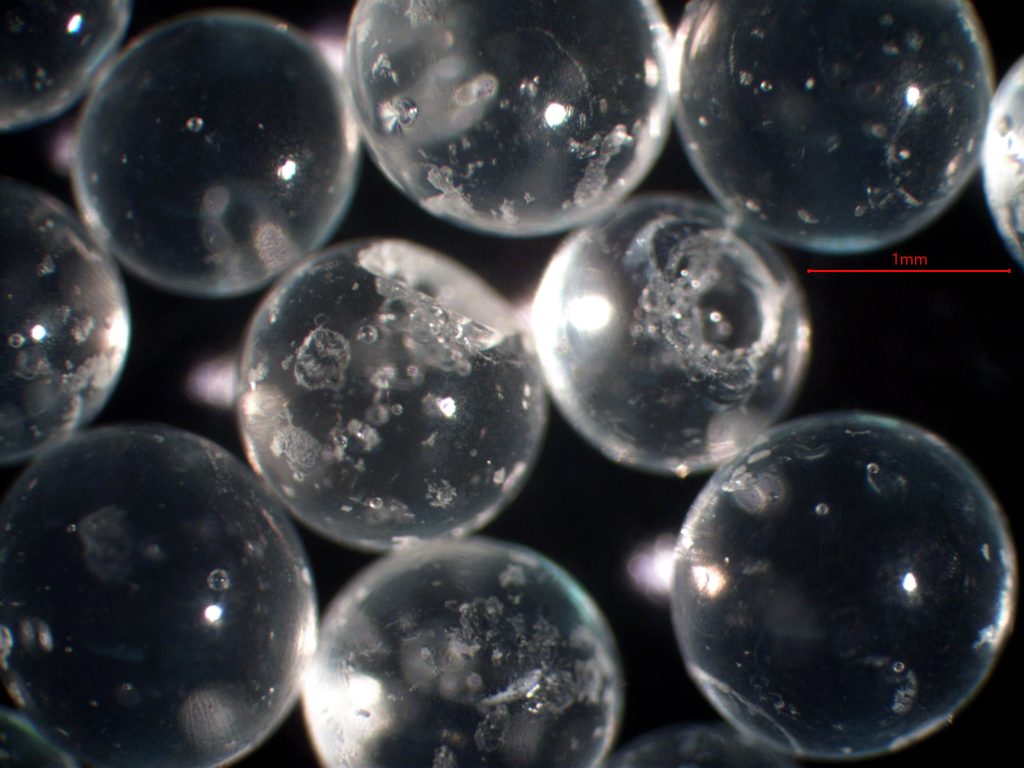

- Determine surface morphology and shapes of particles

- Determine particle sizes

- Map the distribution of elements or examine a particle or area for its elemental composition for carbon and heavier elements

- Offers quick determination of whether carbonates, phosphates, nitrates, nitrites, numerous minerals, or water are present with relative quantitative measurement between several samples

- Measures organic surface coatings and treatments to a 1 to 2 μm depth, often identifying inorganic fill particles in the polymer

- Detect differences in an organic coating thickness over an inorganic substrate material

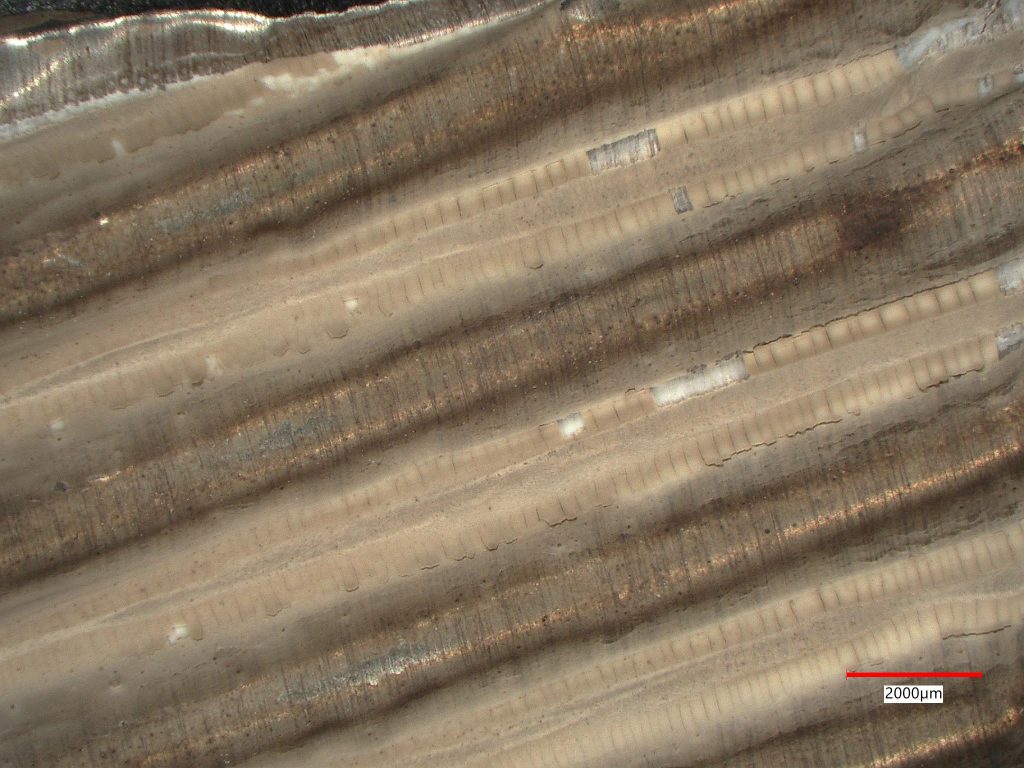

Keyence 3D Optical Microscopy:

- Determine the size and shape of particles, using surface profiles to obtain particle height information

- Use color differences to indicate different chemical phases and their locations

- Use the LIBS enhancement for microanalysis elemental compositions

- Select typical or atypical areas for further analysis by other techniques

- Document the microscopic appearance associated with a spectrum obtained by another analytical technique

ASTM Test Methods:

- ASTM E793 – Standard Test Method for Enthalpies of Fusion and Crystallization by Differential Scanning Calorimetry

- ASTM E794 – Standard Test Method for Melting and Crystallization Temperatures by Thermal Analysis

- ASTM E1131 – Standard Test Method for Compositional Analysis by Thermogravimetry