Introduction

A homeowner contacted us to evaluate the differences in appearance, cleanability, and roughness between two lots of MSI floor tiles. The homeowner raised concerns about these variances. Meanwhile, MSI claims that the wide differences between lots are acceptable. However, many would view this as a lack of quality control. To address these concerns, we have summarized our findings below. These findings include quantitative surface roughness parameters obtained using the Keyence VHX-7000N Digital Optical Microscope.

Summary of Findings

We conducted optical microscopy, surface profilometry, and Laser-Induced Breakdown Spectroscopy (LIBS) analysis on the MSI Cementino Gray Matte Porcelain Floor Tiles. The homeowner labeled these tiles as “Good” and “Bad.” Here are the main results:

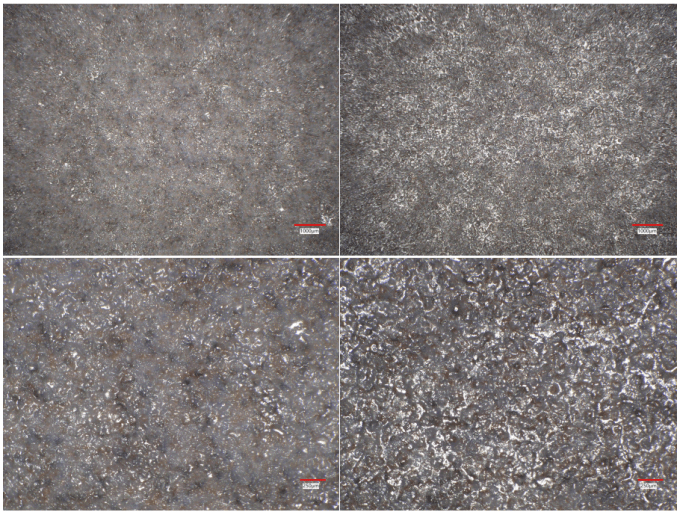

- Reflectivity: The “Good” floor tile reflects more light, whereas the “Bad” tile scatters light. Consequently, they have a different appearance.

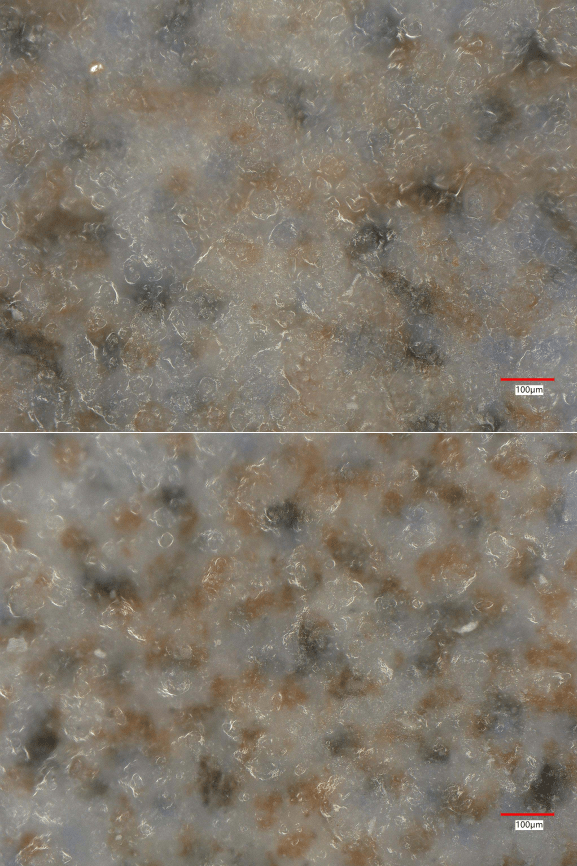

- Glaze Composition: While the glazes on both tiles appear similar, the translucent glaze particles are more evenly distributed on the “Good” tile.

- Melting of Glaze: On the “Bad” tile, the glaze particles are less melted. As a result, the colorant layer beneath is obscured in areas of thicker glaze. This contributes to the differing appearances between the tiles.

- Surface Roughness: The “Bad” tile has significantly greater surface roughness. This affects both light reflectivity and cleanability, making it feel different underfoot and harder to clean.

These findings clearly indicate a lack of quality control by the tile manufacturer. When a buyer is shown a “Good” tile but receives a “Bad” tile, it can feel like a bait-and-switch situation. MSI responded to the homeowner’s complaint via email on March 8, 2024, stating that they are not responsible for differences between tile lots. Therefore, future buyers should be aware that MSI accepts these quality control variances.

Floor Tile Roughness: Samples and Background

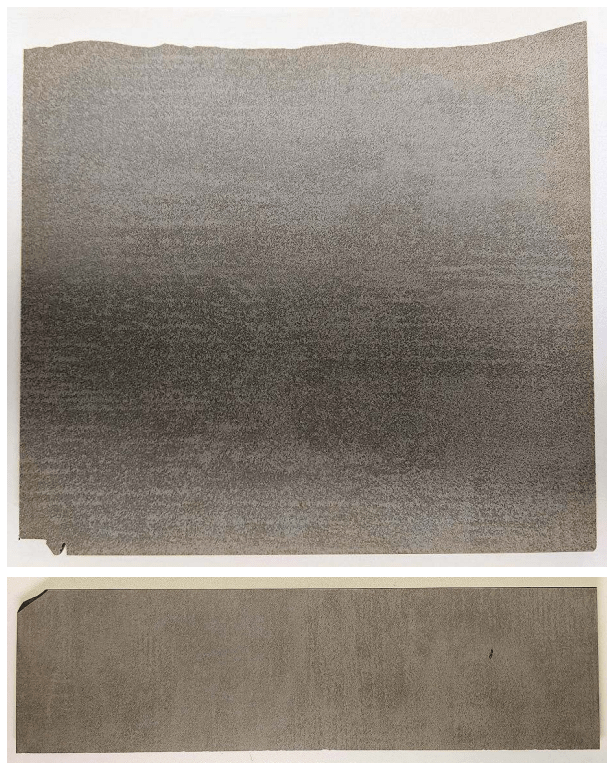

On January 23, 2024, we received samples of MSI Cementino Gray Matte Porcelain floor tiles from the homeowner. These samples were labeled “Good” (Lot 230710) and “Bad” (Lot 230709). The lot numbers suggest that the “Bad” tiles were produced just before the “Good” tiles, indicating a short manufacturing interval. The homeowner noted that the “Good” tiles looked better and were easier to clean. You can see these samples in Figure 1.

Optical Microscopy and LIBS Analysis

We examined the samples using a Keyence VHX-7000N Digital Optical Microscope equipped with an EA-300 Laser-Induced Breakdown Spectroscopy (LIBS) unit.

Digital Optical Microscope:

- Magnification: The lenses provide zoom magnification from 20 to 2000 times using a 4K CMOS image sensor.

- Image Reconstruction: The system captures images at various distances and reconstructs them to show detailed features.

- Lighting: It includes axial through-the-lens, ring lighting, and angled lighting options.

- Measurement Capabilities: The microscope offers 2D and 3D measurements, particle size analysis, grain-size analysis, surface topography profiling, and surface roughness measurements.

LIBS Elemental Analyzer:

- Laser and Crater Formation: The EA-300 LIBS uses a 355 nm laser beam to create a crater about 10 to 20 micrometers in diameter and 5 to 7 micrometers deep on the surface.

- Emission Analysis: The de-excitation of plasma emits radiation analyzed for RGB color intensity, identifying elements from hydrogen to uranium.

- Elemental Analysis: Small areas and particles can be analyzed for elements like H, Li, Be, B, C, N, O, F, Na, Mg, Al, Si, P, S, and heavier elements.

Surface Roughness Measurements:

We measured surface roughness along a line and across a surface area using the following parameters:

- Sz (Total Height: Sp + Sv)

- Sa (Arithmetic Mean Deviation)

- Sq (Root Mean Square Deviation)

- Ssk (Skewness)

- Sku (Kurtosis)

- Sp (Maximum Peak Height)

- Sv (Maximum Valley Depth)

Images of Floor Tile Roughness

Conclusion

In conclusion, our analysis highlights significant differences between the two tile lots. The “Bad” tiles exhibit higher surface roughness, less even glaze application, and a different appearance compared to the “Good” tiles. These variations strongly suggest a lack of quality control by the manufacturer.

Contact Us

If you have any questions about this analysis or need further assistance with your materials, please feel free to contact us. Our team is ready to help you understand and solve your materials problems.

If you would like to see the rest of the analysis, you can see the full report here.