At Anderson Materials Evaluation, we specialize in comprehensive coating analysis and paint testing to address various challenges in material science. Our laboratory offers detailed services, focusing on the identification and evaluation of coatings and painted surfaces across multiple industries including electronics, aerospace, automotive, and construction.

This is a summary of our services. For a more detailed look, check out our page “Coating and Paint Analysis – An in Depth Look“.

Our Coating Analysis Capabilities Include:

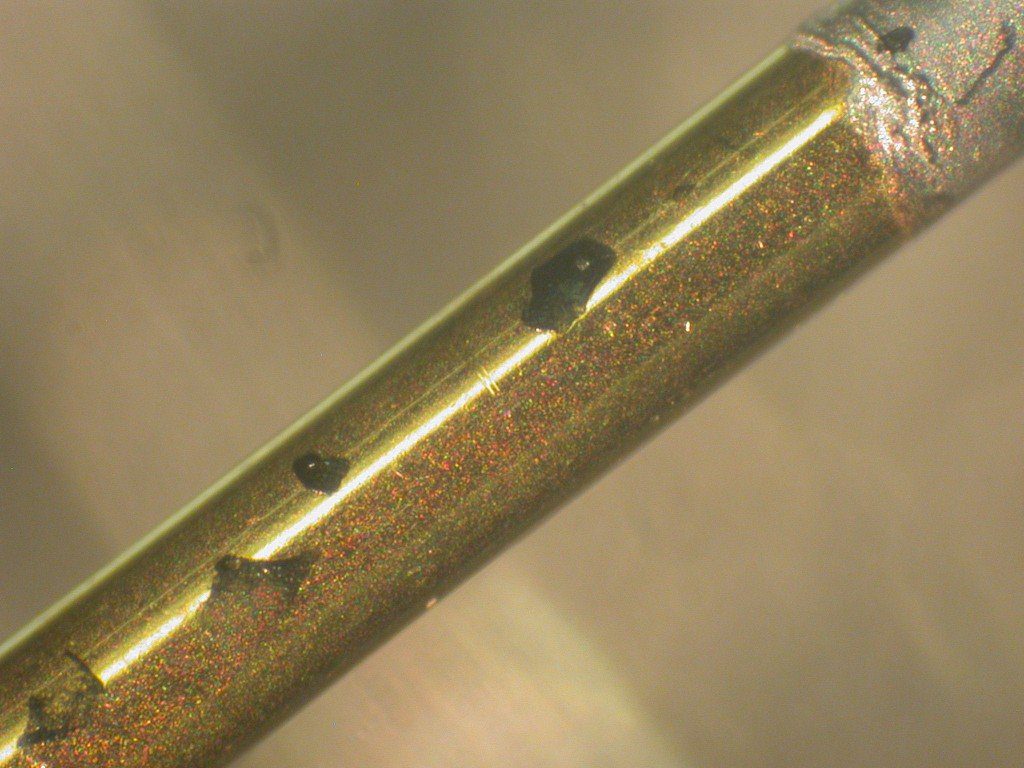

- Coating Thickness Analysis: Techniques such as cross-sectional metallography and radial sectioning for accurate measurement of coating thickness and finding of voids.

- Material Composition Identification: Using FTIR, XPS, and other spectroscopic methods to determine the chemical composition of coatings, binders, and fillers.

- Degradation and Performance Testing: Evaluation of coatings for resistance to UV exposure, thermal degradation, and other environmental factors.

- Surface Contamination and Adhesion Testing: Detection of surface contaminants and comprehensive adhesion testing to ensure coating integrity.

- Mechanical and Thermal Testing: Analysis of the physical properties and curing states of coatings using DSC, TMA, and hardness tests.

Techniques We Utilize:

- X-ray Photoelectron Spectroscopy (XPS): Determining the chemical composition and electronic states of elements within the coating layers.

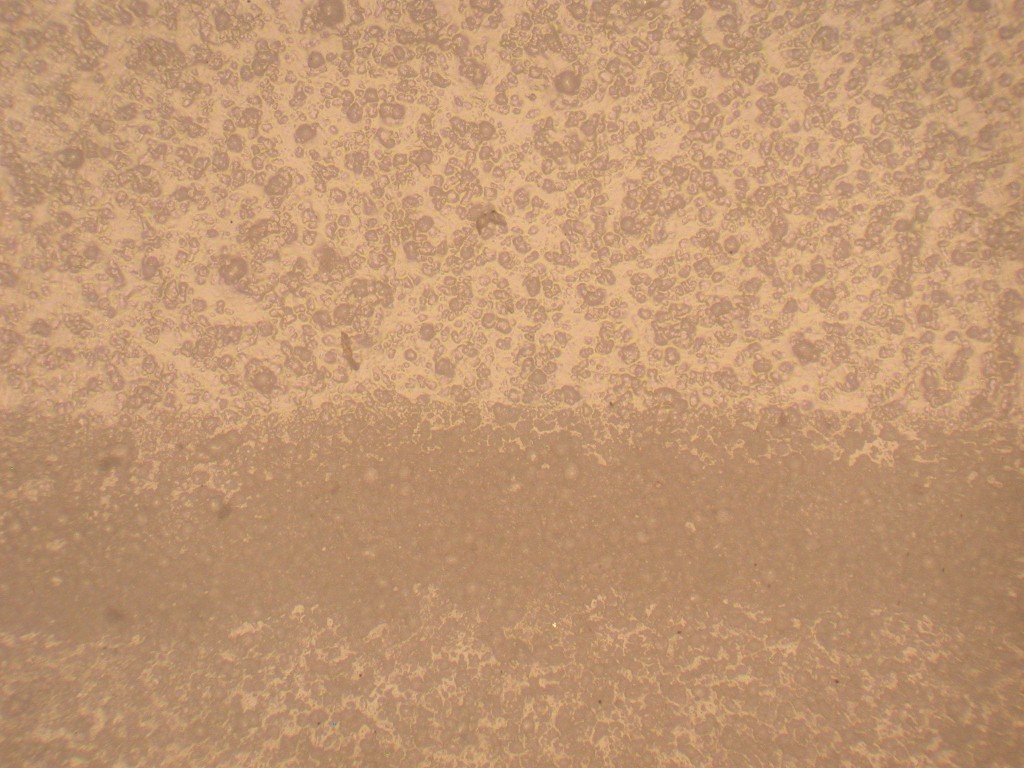

- SEM/EDX Analysis: Detailed surface and cross-sectional examination of coatings to assess texture and composition.

- Infrared Spectroscopy (FTIR): Analysis of organic coatings and detection of various chemical compounds within them.

- Gas Chromatography – Mass Spectroscopy (GC-MS): Separation and identification of organic components in coatings.

- Differential Scanning Calorimetry (DSC): Study of phase changes and melting temperatures in coatings.

- Thermomechanical Analysis (TMA): Measurement of thermal expansion, softening temperatures, and glass transition temperatures.

- Thermogravimetric Analysis (TGA): Analysis of oxidation behavior, weight loss upon heating, and content of volatile components.

- Corrosion Testing: Identify causes of corrosion.

- Contact Angle Measurements: Evaluation of surface energy before and after coating application.

- Viscometry: Measurement of the viscosity of liquid paints and emulsions to ensure application consistency.

- Profilometry: Measurement of surface roughness and topography for precise coating applications.

- and more!

Application Areas:

- Protective Coatings: Aerospace, defense, automotive, and construction.

- Functional Coatings: Including anti-reflective, thermal protection, and hydrophobic coatings.

- Specialty Coatings: Such as radar absorption, sensor coatings, and coatings for electronics.

Our extensive expertise in coating and paint analysis ensures that we can provide precise solutions for your materials challenges. Contact us to learn more about how our services can benefit your projects.