X-ray diffraction (XRD) analysis is a powerful technique used to identify and analyze crystalline materials. It determines the chemical phases present in a material and the ratio of crystalline to amorphous phases. Our XRD analysis provides valuable insights into a wide range of applications, from mineral composition to polymer crystallinity. Whether you’re dealing with powders, solids, or surface layers, XRD can offer detailed information about your material’s structure and composition.

What XRD Analysis Can Do for You

1. Identify Chemical Phases:

XRD reveals the chemical phases in your sample. This information is crucial for understanding material properties and behavior.

2. Determine Phase Percentages:

With XRD, we can accurately quantify the percentage of each chemical phase in a sample. This helps you understand the material’s composition and how it might react under different conditions.

3. Analyze Inorganic Fill Particulates:

XRD identifies inorganic fill particles added to polymers. This ensures that your materials meet specifications and perform as expected.

4. Examine Metal Alloys:

For metal alloys, XRD identifies chemical phases and evaluates structural integrity. This is essential for quality control and product development.

5. Measure Polymer Crystallinity:

Understanding the degree of crystallinity in polymers helps in predicting material properties such as strength, flexibility, and thermal behavior.

6. Investigate Surface Layers:

XRD can analyze thin films and surface coatings, providing insight into the composition and thickness of layers. This is valuable for applications in electronics, optics, and protective coatings.

7. Evaluate Thin and Thick Films:

From electronic devices to protective coatings, XRD assesses the chemical phase composition of films, ensuring optimal performance and durability.

Advantages of XRD Analysis

Comprehensive Material Insight:

XRD provides a detailed look at the internal structure and composition of materials, which can guide manufacturing processes, quality assurance, and research.

Accurate Quantification:

With techniques like Rietveld refinement, XRD delivers precise measurements of chemical phase percentages, offering reliable data for decision-making.

Versatile Applications:

Whether you’re working with minerals, polymers, metals, or ceramics, XRD adapts to a wide range of materials and industries.

Surface and Bulk Analysis:

XRD is effective for both surface-level investigations and deeper material analysis, making it suitable for various research and industrial applications.

Comparison to Other Analysis Techniques

XRF Analysis:

XRF is useful for detecting heavy elements deeper within a sample. However, XRD excels in identifying crystalline phases and quantifying their proportions.

EDS Analysis:

While EDS provides elemental composition, XRD offers a more in-depth understanding of the material’s crystalline structure and phase composition.

XPS Surface Analysis:

XPS focuses on surface-level elements, whereas XRD can analyze both surface and deeper layers, providing a more comprehensive view of material composition.

Case Studies and Examples

1. Mineral Composition Analysis:

XRD was used at AME to successfully identify the mineral composition of various geological samples, providing insights into their formation and potential applications.

2. Polymer Crystallinity Assessment:

In polymer science, XRD helps determine the degree of crystallinity, influencing material selection and design.

3. Metal Alloy Evaluation:

For industries like aerospace and automotive, XRD offers crucial data on metal alloys, ensuring safety and performance standards are met.

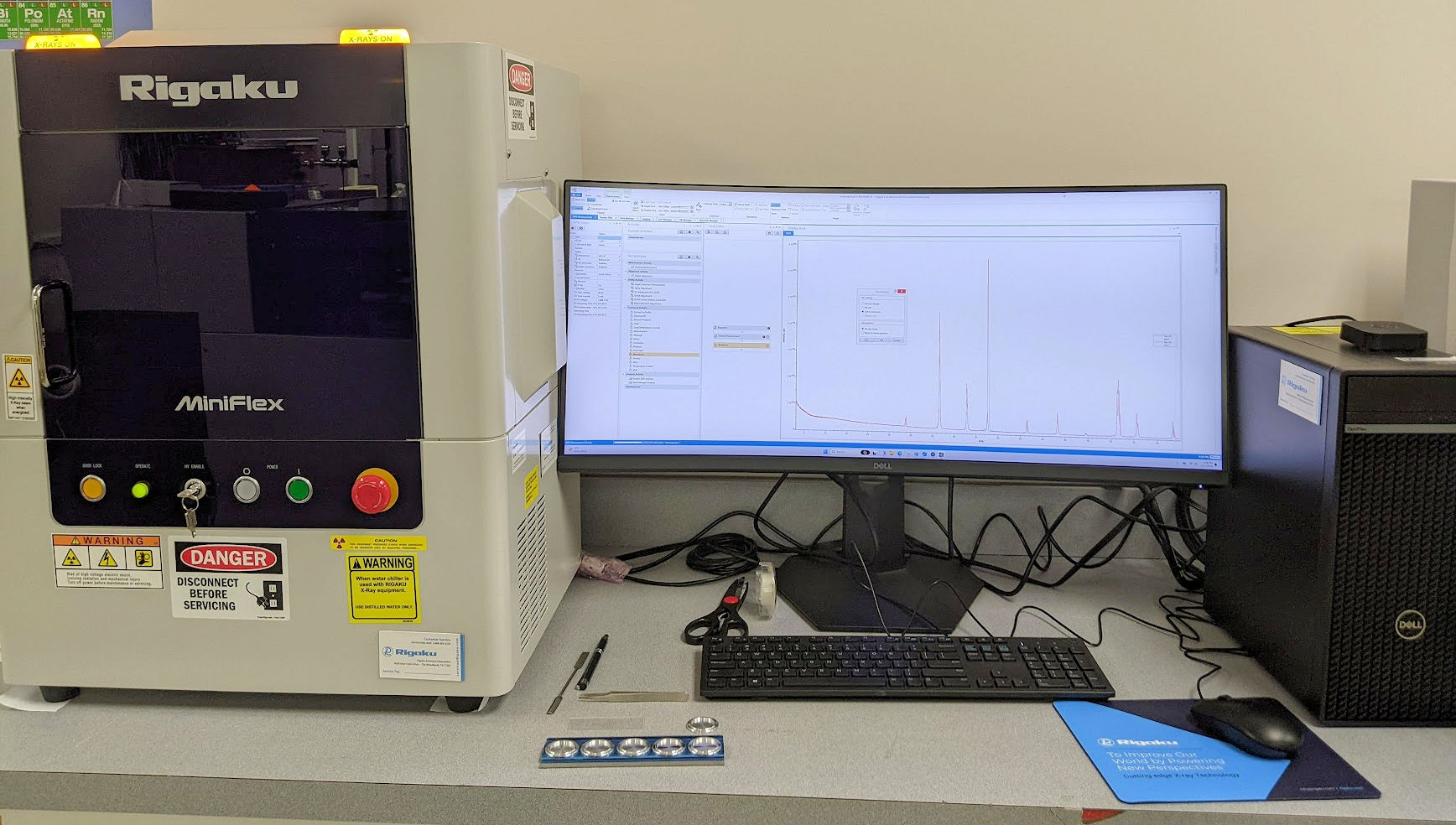

Rigaku MiniFlex 6G XRD System at AME Laboratories

Our advanced Rigaku MiniFlex 6G XRD system enables us to offer precise and reliable analysis. Here are some features that make our XRD analysis stand out:

- High-Resolution Detection:

Our system uses a 600W Copper X-ray source and a D/teX Ultra 0D/1D high-speed detector for accurate data collection. - Versatile Sample Handling:

An 8-position sample changer with a sample spinner allows us to analyze multiple samples efficiently. - Comprehensive Analysis Range:

The goniometer range of -3 to 145 degrees 2-theta, coupled with Rietveld refinement capabilities, allows for a detailed and thorough analysis of various materials. - Low-Angle Optimization:

A variable knife edge optimizes low-angle detection without blind spots, enhancing data accuracy.

Contact Us

At AME Laboratories, we specialize in advanced XRD analysis for a variety of materials. Our expert team is ready to help you uncover the details of your material’s composition and structure. For more information or to discuss your specific analysis needs, please contact us today.