Comprehensive Thin Film Testing

Anderson Materials specializes in Thin Film Analysis, offering comprehensive services to assess and analyze thin films across a wide range of applications. Our expert analysis helps ensure the quality and performance of your thin film materials.

Thin Film Analysis Services We Offer

XPS Analysis (10 nm depth)

- Surface analysis: Analyzes surface chemistry and film stoichiometry for sputtered or CVD films to understand their chemical makeup and structure.

- Elemental composition testing: Reveals elemental composition as depth varies, which is crucial for examining:

- Multilayer film structures like anti-reflective coatings and metallization layers, providing insights into their composition and layering.

- TiN coatings on biomedical devices, ensuring their integrity and ability to function.

- Contamination detection: Detects interface contamination and measures surface hydration to identify potential sources of material degradation or performance issues.

- Failure analysis: Performs failure analysis for delamination problems to finding the causes and mechanisms behind film separation.

- Reaction analysis: Determines if film layers have reacted or if boundaries are sharp, finding the stability and integrity of the film structure.

- Temperature-dependent analysis: Analyzes diffusion and reactions with temperature variations to understand how films interact with their environment under different thermal conditions.

FTIR Analysis (1-2 micrometer depth)

- FTIR Analysis: Detects and identifies thin organic or polymer films on metal or semiconductor surfaces, providing detailed chemical composition analysis up to depths of 1-2 micrometers.

- Corrosion prevention identification: Identifies thin organic films used to prevent corrosion in structures, providing long-term durability and reliability.

- Metallization film identification: Identifies plastics or polymers with metallization films, crucial for applications that require increased conductivity or protective coatings.

Thin Film Thickness Measurements

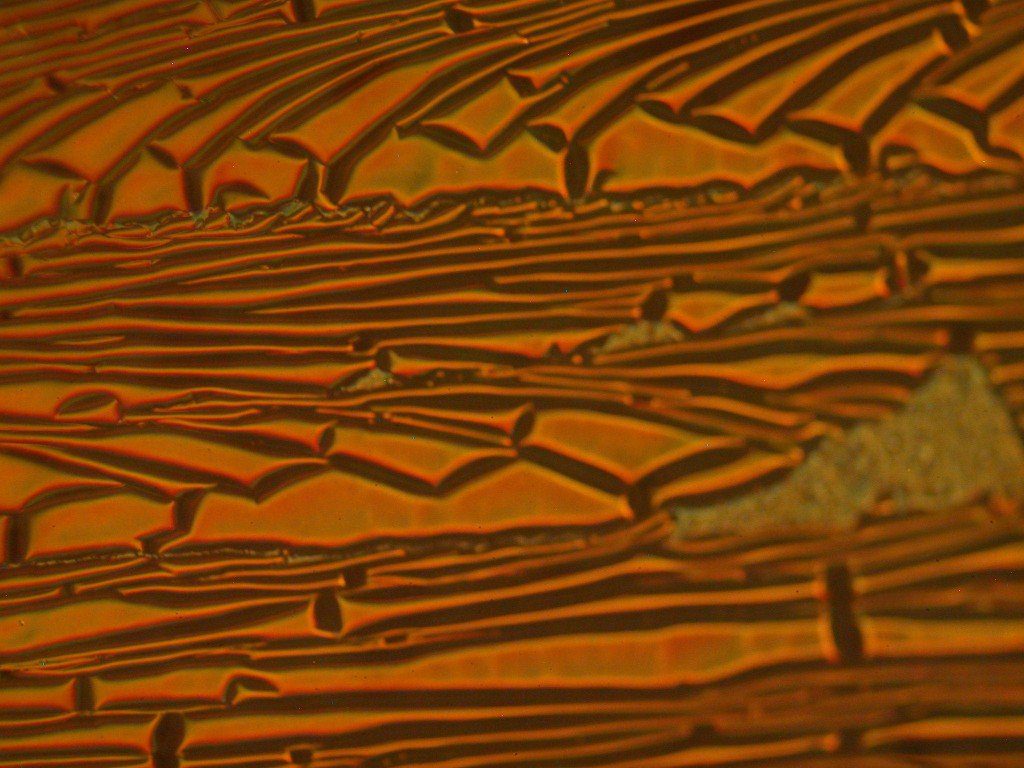

- Cross–section analysis: Utilizes SEM or metallographic microscopy for cross-sectional imaging, which allows for detailed analysis of layer thickness and structure.

- Precise measurements: Provides accurate measurements of layer thickness, critical for leading to improved performance in various applications.

- Advanced analysis: Utilizes depth profile or angle-resolved XPS techniques for testing very thin films, offering insights into compositional variations and interfaces.

Profilometry and Surface Microscopy

- Surface profilometry services: Measures surface roughness and creates 3D topography maps to see surface features and texture.

- Defect detection: Detects defects as small as 500 nm, giving the chance for improved quality and reliability in thin film applications.

- Dimensional measurements: Measures 2D and 3D distances accurately, providing detailed geometrical insights into thin film structures.

Laser-Induced Breakdown Spectroscopy (LIBS)

- Composition analysis: Quickly determines the major composition of thin films using Laser-Induced Breakdown Spectroscopy (LIBS).

- Element identification: Identifies elements such as aluminum, calcium, sodium, lead, or boron at high concentrations in thin films.

Reactivity of Thin Film

- Gas reaction analysis: Offers TGA measurement to assess film weight gain due to reactions with gas.

- Oxidation assessment: Utilizes TGA testing to assess oxidation protection provided by thin films.

- Heat reaction measurement: Measures exothermal and endothermal heat reactions using DSC to understand film reactivity.

Corrosion Testing

Cross-section analysis: Performs detailed analysis for:

- Thickness measurements: Conducts measurements of various materials.

- Assessment of grain size and orientation.

- Detection of inclusions and evaluation of uniformity.

- Identification of observable phases such as carbides, intermetallic phases, and graphite microclusters.

Adhesion Failures

- Failure analysis: Conducts analysis of peeled or delaminated thin films.

- Identifies locus of failure, finding contamination, hydration, or reacted layers using XPS and FTIR.

- Examines mode and locus of failure using metallographic microscopy or SEM.

Learn More

For more details about our Thin Film Analysis services, please visit our detailed page. Contact us here to discuss your thin film testing needs and benefit from our expertise. Our team of Ph.D. scientists is ready to help you address material challenges and improve your processes.