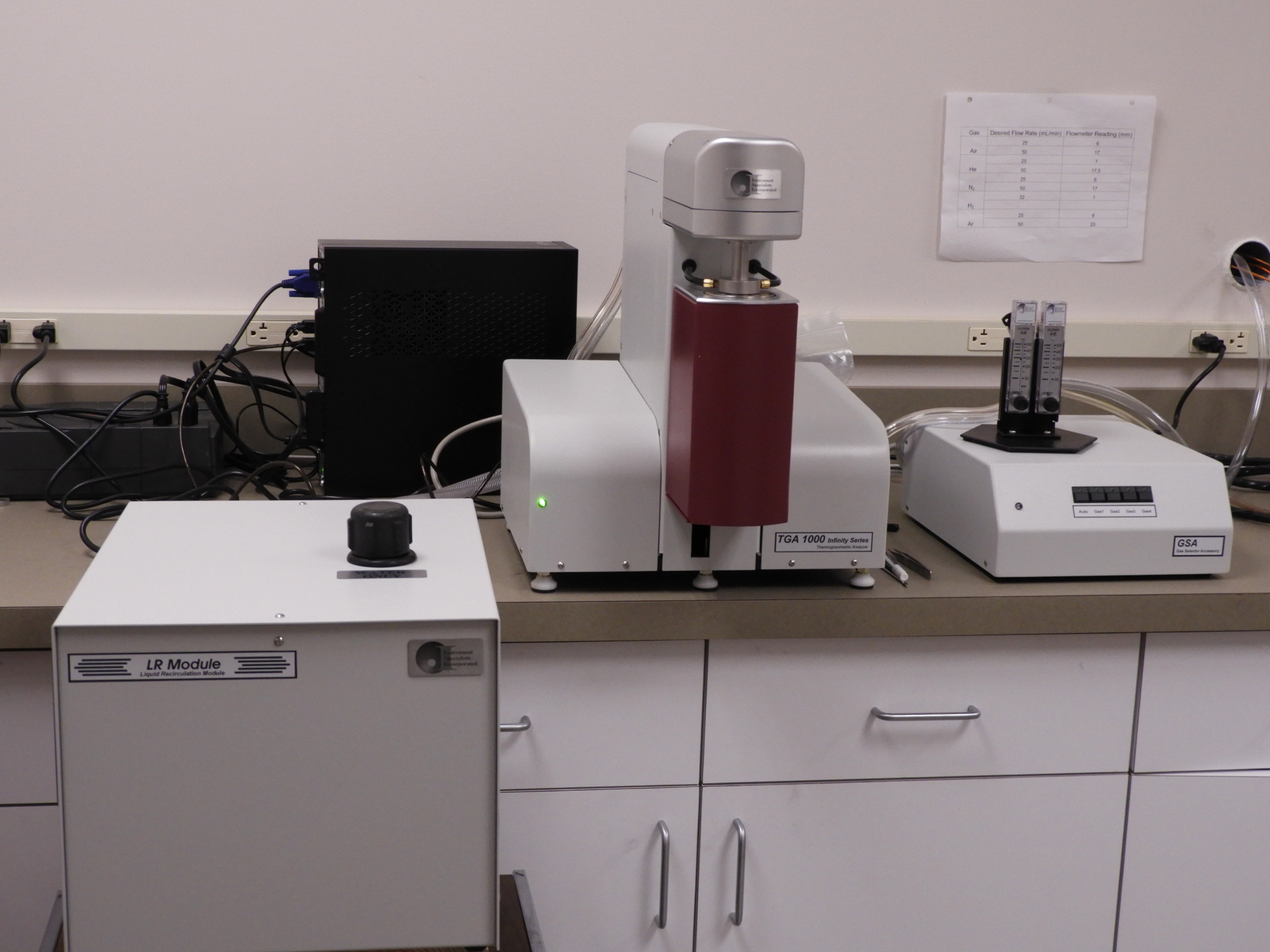

TGA Analysis, also known as Thermogravimetric Analysis (TGA) or Thermogravimetry, measures the weight of a material sample. It does this either as a function of increasing temperature or isothermally over time. This occurs in an atmosphere of nitrogen, helium, air, or other gases. The weight changes are accurately measured, providing critical data on the material’s properties.

TGA can interface with a mass spectrometer RGA to identify and measure vapors made during the process. This enhances sensitivity, especially when performed in an ultrahigh vacuum system. TGA analysis is flexible, applicable to inorganic materials, metals, polymers, ceramics, glasses, and composites.

Applications for TGA Analysis

- Decomposition Reactions: Determines temperature and weight changes, allowing for quantitative composition analysis of materials.

- Formulation Analysis: For multi-component materials and blends.

- Water Content: Determines the amount of leftover solvents or water in materials.

- Reactive Gases: Analyzes reactions with air, oxygen, or other gases.

- Evaporation Rates: Measures volatile emissions of liquid mixtures.

- Material Identification: Identifies plastics and organic materials by their bond scission or oxidation temperatures (their breaking or burning temperatures).

- Fill Material Measurement: Assesses fill materials like carbon black, TiO2, and more in plastics, laminates, composites, and other materials.

- Food Analysis: Measures fill materials in foods, such as silica gels and calcium carbonate.

- Purity Determination: Determines purity of minerals, inorganic compounds, or organic materials.

- Mineral Composition: Distinguishes different mineral compositions.

- Quality Control: Ensures products meet material specifications.

- Polymer Degradation: Assesses degradation in recycled polymer resin compared to virgin resin.

- Carbon Nanotubes (CNT): Analyzes purity and compares CNT samples from various sources.

- Desorption and Absorption: Measures weight loss or gain of absorbed liquids or gases in porous materials.

Standards and Methods

Anderson Materials Evaluation is able to perform the following test methods:

- ASTM D2584: Ignition loss of cured reinforced resins.

- ASTM D3850: Standard thermogravimetric method.

- ASTM D5967: Evaluation of diesel engine oils.

- ASTM D6370: Rubber compositional analysis by thermogravimetry.

- ASTM D6375: Evaporation loss of lubricating oils (Noack Method).

- ASTM E1131: Compositional analysis by thermogravimetry.

- ASTM E1641: Decomposition kinetics by thermogravimetry.

- ASTM E1877: Calculating thermal endurance from decomposition data.

- ASTM E2008: Volatility rate by thermogravimetry.

- California Department of Pesticide Regulation TGA VOC Tests: Measures volatile emission potential of pesticides.

TGA Analysis Case Histories

- Fiberglass Reinforced Nylon-6 Pellets: Characterization for injection molding.

- Calcium Carbonate: Purity analysis.

For a detailed explanation of the TGA analysis services at Anderson Materials Evaluation, please visit our Comprehensive TGA Analysis Services page. Our team of scientists are happy to be able to help you and your company improve your materials.

Contact us

If you have any questions or need more information about our TGA analysis services, please contact us. Our team is ready to help with your needs and provide expert guidance.