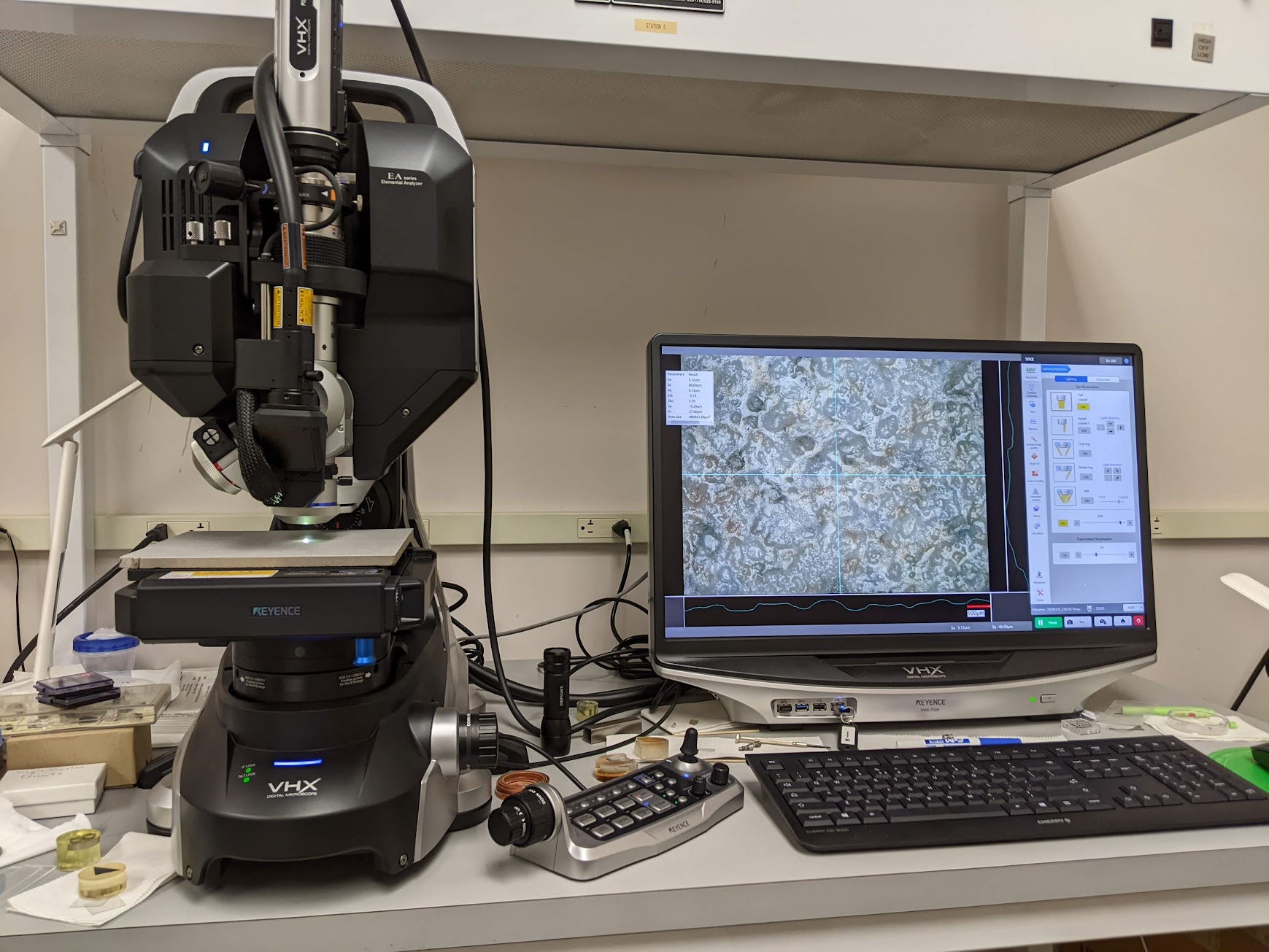

Keyence 7000N Profilometer

The Keyence 7000N accurately measures surface profiles and roughness, providing detailed information about the surface characteristics. The device captures surface profiles along both the center horizontal and vertical lines of the observed area. It also lists various surface roughness parameters, giving a comprehensive analysis of the surface.

Keyence 7000N Digital Optical Microscope

The Keyence 7000N Digital Optical Microscope uses its automatic multi-focusing planes to measure the distance between focal planes for microscopic features. With its impressive magnification range from 20X to 2000X, the microscope can capture even the smallest details. Furthermore, it uses either ring or coaxial illumination to ensure clarity and precision in measurements. Moreover, it includes an optional software package for surface profilometry and roughness measurements, enhancing its capabilities.

The device can measure linear and surface roughness parameters both along a line and across a surface area. You can reference the 3D-focused surface to a fitted plane for tilt correction or to fitted spheres or cylinders, ensuring accurate measurements. The Keyence 7000N measures several key surface parameters, including:

- Sa: Arithmetic Mean Deviation

- Sq: Root Mean Square Deviation

- Ssk: Skewness

- Sku: Kurtosis

- Sp: Maximum Peak Height

- Sv: Maximum Valley Depth

- Sz: Combined Peak Height and Valley Depth (Sz = Sp + Sv)

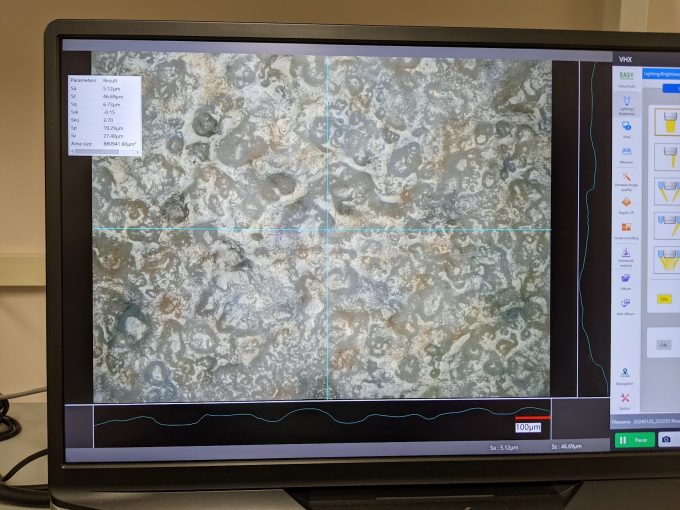

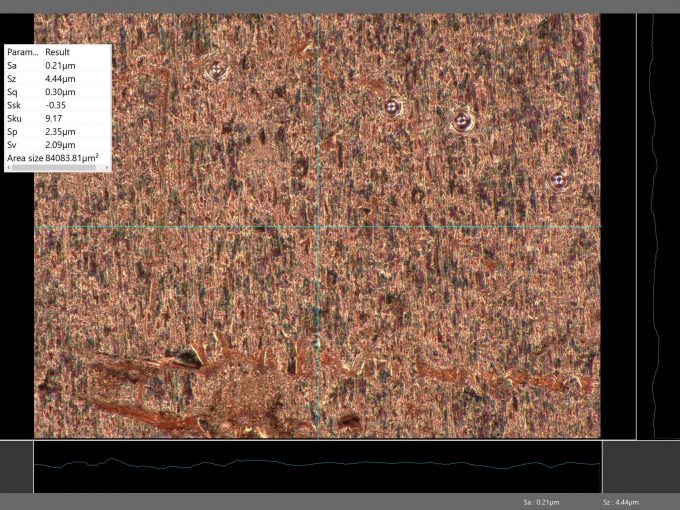

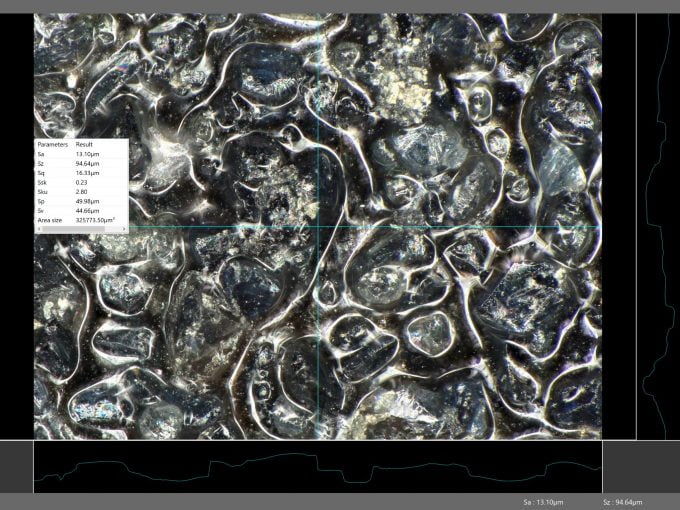

Examples of Surface Profilometry and Roughness

- Rough Floor Tile Surface– At 300X magnification, the surface profile of a rough floor tile reveals vertical and horizontal profiles. As a result, the surface roughness parameter, Sa, is determined to be 5.12 microns. This measurement highlights the uneven texture of the floor tile, which is essential for understanding its surface characteristics.

- Copper Coating on Fiberglass-Reinforced Epoxy Board– When examining the copper coating at 1000X magnification using ring illumination, the device provides detailed vertical and horizontal surface profiles. Subsequently, the surface roughness parameter, Sa, is measured at 0.21 microns. This precise measurement indicates the smoothness of the copper coating, which is crucial for ensuring its performance in applications.

- Used SiC Abrasive Paper (240 Grit)– At 500X magnification, the roughness of the used SiC abrasive paper becomes evident with the aid of ring lighting. The surface roughness parameter, Sa, is found to be 13.10 microns. This high roughness value demonstrates the abrasive nature of the paper, which is vital for its effectiveness in sanding and grinding tasks.

Contact Us

If you need additional information on surface profilometry and roughness measurements or want to discuss how we can assist with your specific needs, please contact us at Anderson Materials Evaluation. Our team of experts is eager to provide detailed insights and tailored solutions. You can reach us via phone, email, or our online contact form. We look forward to assisting you!