At Anderson Materials Evaluation, we take pride in providing precise and comprehensive mechanical testing services, including the shear strength test of epoxy adhesive bonded 316L stainless steel. With our scientific expertise, we ensure our clients receive accurate and reliable data to meet their material evaluation needs.

Overview of the Shear Strength Test

Our shear strength test actively measures the apparent shear strength of single-lap-joint adhesively bonded metal specimens under tension loading. We follow the ASTM D1002 standard to deliver valuable insights into the adhesive bond strength of materials, which are crucial for engineering and industrial applications.

Test Specimen Preparation

Our team strictly adheres to the ASTM D1002 standard, ensuring we achieve consistent and accurate results every time. Here’s a detailed breakdown of how we prepare the test specimens:

- Material Used:

- Metal Specimens: We use 316L Stainless Steel to guarantee durability and strength.

- Adhesive: Our tests utilize a one-component epoxy adhesive, chosen for its excellent bonding properties.

- Surface Preparation:

- Polishing: We polish the metal surfaces with abrasive paper to create a smooth finish.

- Cleaning: We rinse each specimen with water and isopropyl alcohol to remove contaminants.

- Drying: The specimens are thoroughly dried in laboratory air to ensure no moisture affects the bonding process.

- Adhesive Application:

- Bonding Process: We apply the epoxy adhesive evenly on the surface of the metal coupons.

- Weight Application: A weight is strategically applied to ensure even bonding across the surfaces. Additionally, we remove excess adhesive from the edges to clearly define the bonding area.

- Curing:

- Temperature: The specimens undergo curing at 176 °C for 10 minutes in an oven, following the epoxy adhesive manufacturer’s recommendations.

ASTM D1002 Test Procedure

Next, we move on to the shear strength test, which follows the ASTM D1002 procedure to ensure standardized results. This structured approach allows us to provide our clients with highly accurate and reliable data.

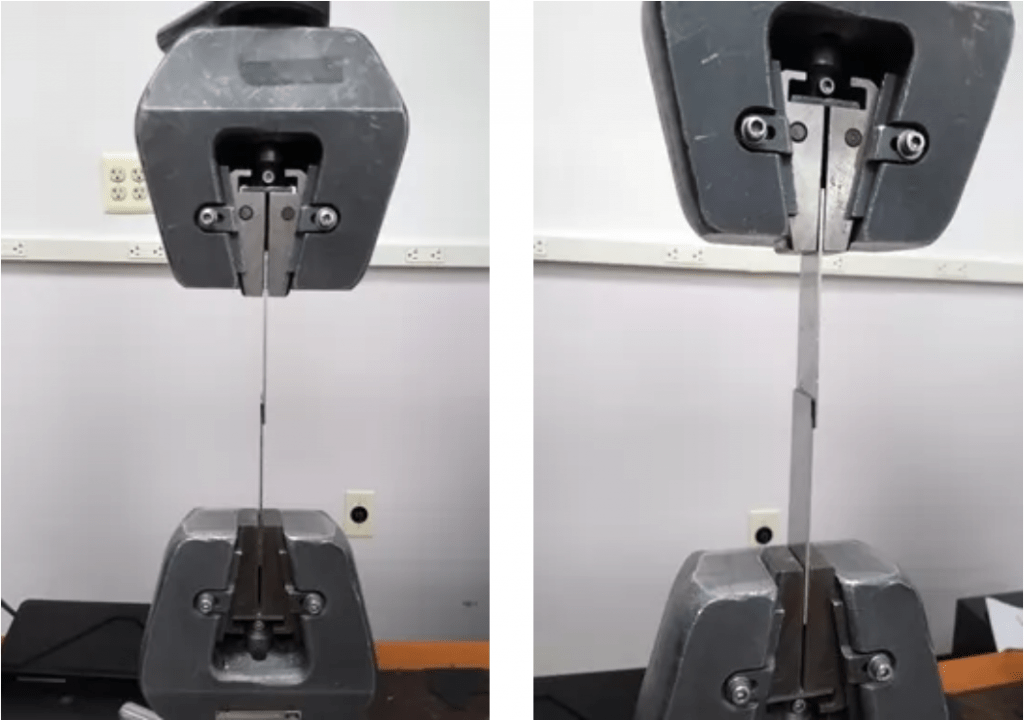

- Testing Equipment:

- Instrument: We use the Instron Model 1125 Universal Testing Instrument, known for its precision and reliability.

- Load Cell Capacity: The instrument has a 10,000 lb load cell, accommodating a wide range of testing requirements.

- Test Setup:

- Specimen Positioning: We place each specimen one inch from both ends in mechanical wedge action grips with coarse serrated faces to ensure a secure hold.

- Crosshead Speed: The test runs at a speed of 1.3 mm/min until failure occurs, allowing us to precisely measure the adhesive bond strength.

Results and Analysis

With the testing complete, we move on to analyzing the results, which provide a comprehensive view of the adhesive bond strength under standardized testing conditions.

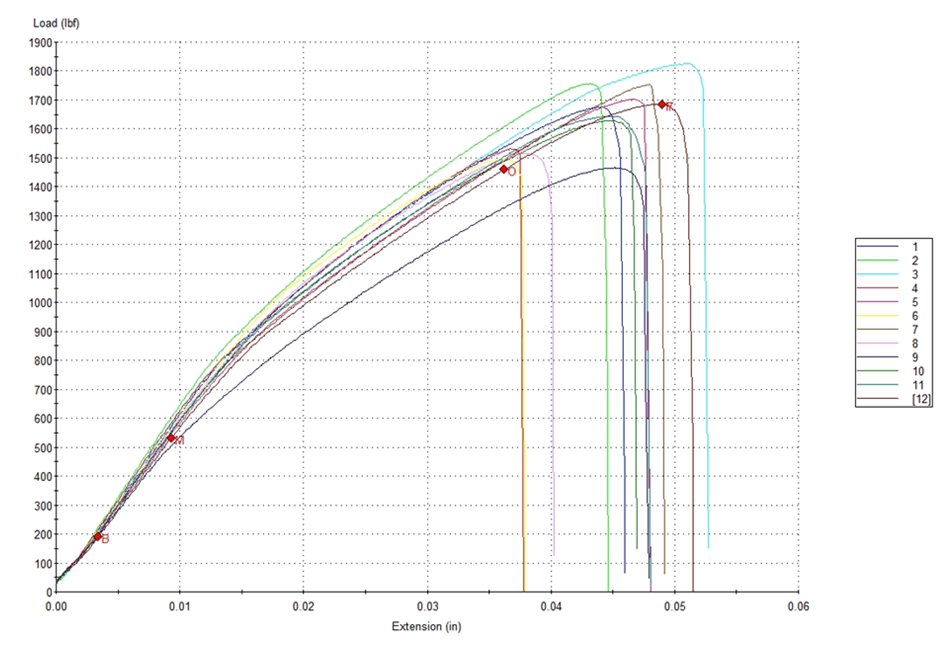

Lap Shear Strength Results

The shear strength test results for the adhesively bonded 316L stainless steel specimens are illustrated in Figure 2. This data provides a detailed analysis of the adhesive bond strength and helps identify areas for improvement.

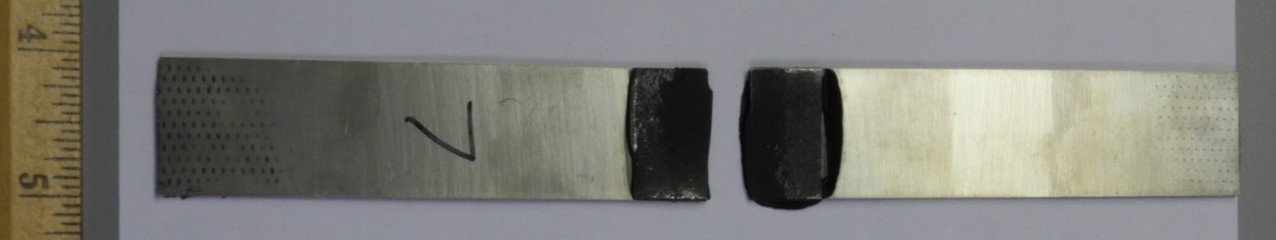

Failure Mode Analysis

After the test, our scientists examine the specimens to assign the failure mode accurately. This analysis is crucial for understanding the performance and reliability of the adhesive bond.

- Failure Mode: Mixed mode cohesive-adhesive failures were observed over the bonded areas. Most specimens, as depicted in Figure 3, exhibited only a small fraction of adhesive failure.

Why Choose Anderson Materials Evaluation?

Choosing Anderson Materials Evaluation means benefiting from the scientific expertise of our team of Ph.D. scientists, led by experts like Priyanshu Banerjee, Ph.D. We offer unparalleled knowledge in mechanical testing and are dedicated to providing accurate and reliable results to support your engineering and research needs.

Contact Us:

To discuss your mechanical testing requirements, please reach out to Dr. Priyanshu Banerjee at priyanshu@andersonmaterials.com, call 1-410-740-8562, or complete a contact form on our Contact Us page.