The static coefficient of friction (SCOF) determines the force needed to start moving an object across a surface. This measurement ensures safety and performance in various environments, from flooring and ramps to manufacturing processes and product testing.

Why Friction Measurement Matters

- Safety: The SCOF is essential for preventing slips and falls on different surfaces. Ensuring that floors, ramps, and walkways have the appropriate traction is critical for both public and workplace safety.

- Manufacturing: In industrial settings, the SCOF affects processes such as stamping and the reliability of electrical and mechanical connections. Proper friction levels can enhance efficiency and product quality.

- Product Testing: By verifying that materials meet safety standards and perform well, manufacturers can ensure their products are reliable and safe.

Our Services

- Slip and Traction Measurements: We use the American Slip Meter, Inc. ASM 825A Digital Slipmeter to accurately measure the SCOF in both dry and wet conditions. This device is calibrated for precise results, ensuring reliable data for safety assessments and product development.

- Standards Compliance: Our measurements adhere to standards like ANSI/NFSI B101.5-2012 and ASTM D2047. These standards help ensure your surfaces meet safety benchmarks.

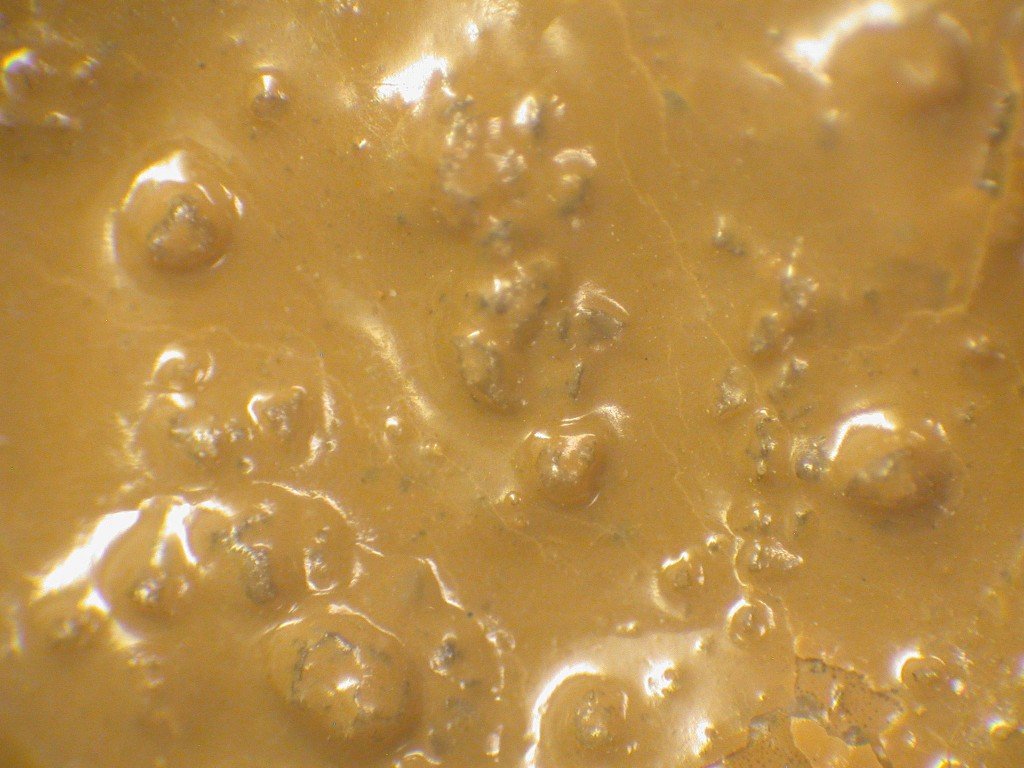

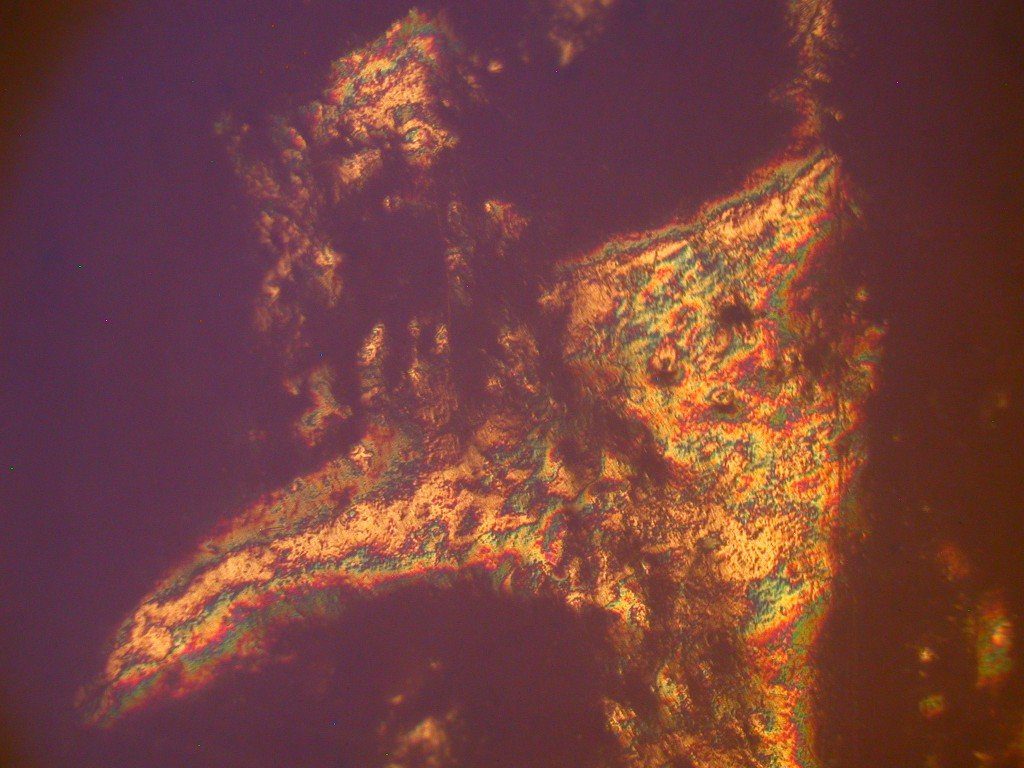

- Detailed Analysis: For complex surfaces, we offer in-depth chemical and morphological analysis. Techniques include XPS, FTIR spectroscopy, optical microscopy, and SEM. These provide a thorough understanding of surface properties, enabling friction optimization.

Applications for Static Coefficient of Friction Measurements:

- Flooring and Walkways: Ensuring safe walking surfaces in commercial, industrial, and residential settings.

- Ramps and Decks: Providing adequate traction for both dry and wet conditions to prevent accidents.

- Manufacturing Processes: Enhancing the performance and reliability of products through better understanding and control of friction properties.

Get More Information on Our Friction Testing Services

For a detailed explanation of our testing methods, standards, and the science behind friction, please visit our comprehensive page here.

Contact Us

If you have any questions or need more information about our static coefficient of friction measurement services, please contact us. Our team is ready to help with your needs and provide expert guidance.