Project Overview: This polymer analysis project involved comparative analysis of two samples of black polymer pellets, supposedly 30% glass-filled Nylon-6, to assist an injection molder in understanding their properties before use. Samples A and B, believed to be similar, are shown in their as received state in Figure 1.

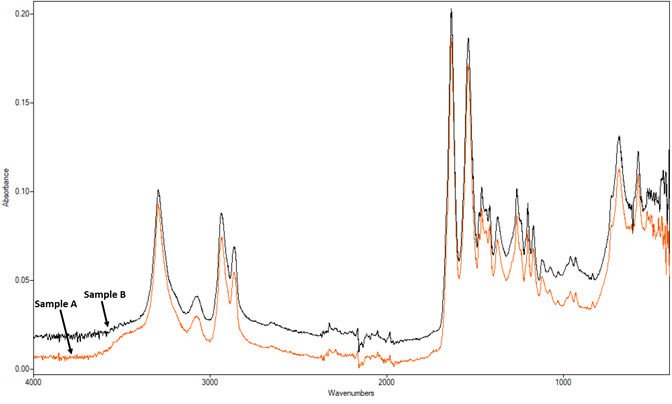

FTIR Polyamide Analysis

The pellets were tested using Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR) to confirm their composition as Nylon-6. FTIR irradiates materials with infrared light to measure absorption characteristic of functional groups, finding specific chemical structures. ATR-FTIR, requiring minimal sample preparation, efficiently tests polymeric materials.

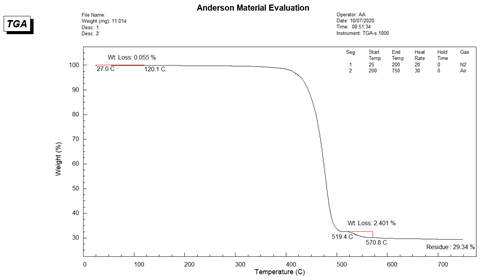

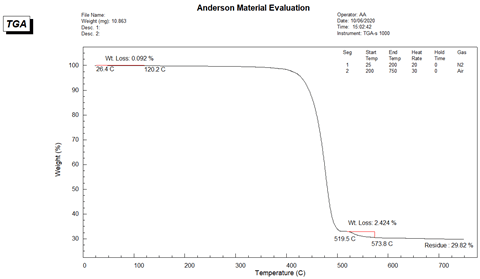

TGA Analysis

Thermogravimetric analysis (TGA) characterized the samples thermally, finding moisture, ash content, and fiberglass weight. Samples went through TGA from room temperature to 750 °C under various purge gases, testing decomposition stages and remaining fiberglass post analysis.

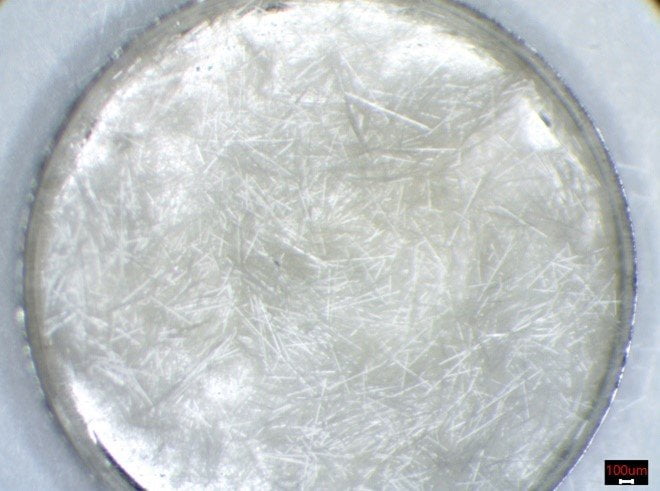

Figure 5. The remaining glass fibers after the TGA run.

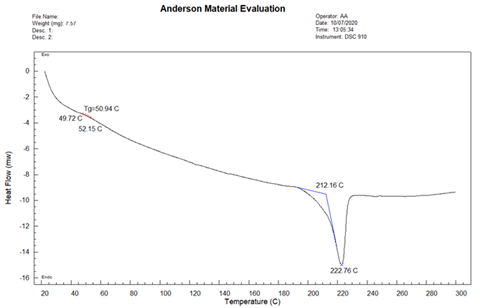

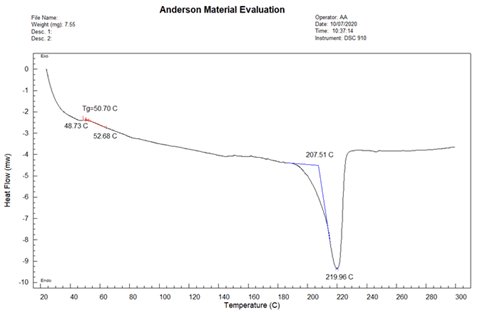

DSC Polyamide Analysis

Differential Scanning Calorimetry (DSC) measured glass transition (Tg) and melting temperatures of the pellets. Heating from room temperature to 300 °C provided thermal profiles, showing differences between molecular weight and polymer chain characteristics between Samples A and B.

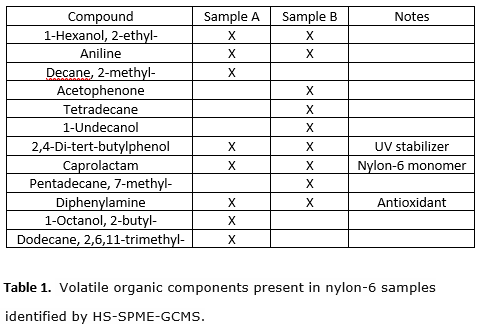

HS-SPME-GC-MS Analysis

Head Space-Solid Phase Microextraction (HS-SPME) coupled with Gas Chromatography-Mass Spectrometry (GC-MS) analyzed volatile organic compounds in the pellets. This solvent-free technique identified organic components, including caprolactam, UV stabilizers, and aniline.

Polyamide Analysis Conclusions

This comprehensive polymer analysis provided insights into water content, nylon-6 resin properties, carbon black and fiberglass content, thermal behaviors, chain lengths, and volatile organic compounds present in Samples A and B.

Contact Us

For more information on polymer analysis or inquiries regarding our services, please contact us. We welcome discussions and collaborations related to plastic, nylon, and polyamide analysis.