Samples Analyzed

We analyzed two samples of polyethylene fibers, labeled BTFS-315D and BTFS-405D, to conduct a surface chemistry analysis. Our study aimed to examine both the surface coatings and the underlying polyethylene fiber surfaces.

Surface Cleaning Process

We cleaned each sample using Kimwipes® soaked in isopropyl alcohol (IPA) to remove surface organic materials and contaminants. We tested the effectiveness of cleaning using X-ray Photoelectron Spectroscopy (XPS).

XPS Analysis Method

XPS analysis was done using a monochromatic aluminum Kα x-ray, covering an elliptical area with detailed elemental surveys. This method provided insights into the elemental composition and depth profile of the tested surfaces, with a depth sensitivity of approximately 8 nm.

Key Findings:

- Initial Surface Composition:

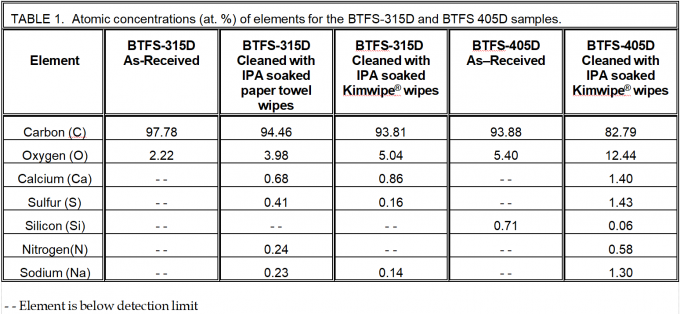

- BTFS-315D: Predominantly carbon (97.78 at.%), with a minor presence of oxygen (2.22 at.%).

- BTFS-405D: Lower carbon content (93.88 at.%), higher oxygen (5.40 at.%), and trace silicon (0.71 at.%).

- Effect of Cleaning:

- Post-cleaning, the BTFS-315D sample showed a composition including carbon, oxygen, calcium, sulfur, nitrogen, and sodium.

- Similarly, the BTFS-405D sample exhibited increased oxygen content post cleaning, along with detectable levels of calcium, sulfur, sodium, nitrogen, and silicon.

- Surface Coating Analysis:

- The surface coatings identified were not typical polyvinyl alcohol or polyvinyl acetate but looked like oils or waxes based on their elemental ratios.

Implications

The presence of these coatings may influence fiber handling, processing during sintering, and the ballistic absorption properties of the final polyethylene product. Further solvent extraction and spectroscopic analysis could provide deeper insights into the nature and impact of these coatings on polyethylene fiber surfaces.

Contact Us

For more information or inquiries regarding this study, please contact us! We welcome any questions or collaboration opportunities related to fiber surface analysis and characterization.