Discover Anderson Materials Evaluation’s comprehensive Metallographic Analysis Services. Metallography is pivotal in studying the structure of metals and alloys, offering crucial insights into material properties and integrity. Our metallographic analysis services can help identify metals and alloys, determine whether an alloy was made correctly, examine multiple phases within a material, locate and characterize imperfections such as voids or impurities, and observe damaged or areas falling apart in failure analysis investigations.

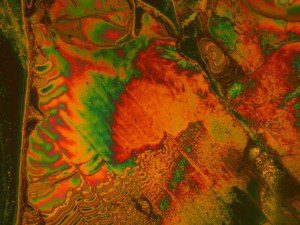

We employ advanced microscopic techniques, including optical and scanning electron microscopy (SEM/EDX), to conduct thorough metallographic analysis. XPS is also used to measure and identify carbides, graphitic inclusions, and intermetallic formations.

Explore detailed Metallographic Case Studies and ASTM Test Methods on our dedicated Metallographic Analysis page.

Our Metallographic Analysis Services include:

- Microscopic Examination: Using advanced techniques such as optical and scanning electron microscopy (SEM/EDX).

- Alloy Identification: Determine alloy composition and processing accuracy.

- Phase Analysis: Identify multiple phases within materials.

- Defect Detection: Locate and characterize imperfections like voids, impurities, and damage.

- Failure Analysis: Investigate areas affected by degradation or structural issues.

We employ modern equipment, including the Olympus PMG-3 Metallographic Microscope made for detailed inspections. From grain size and structure to carbide formation and chemical microsegregation, our analyses adhere to ASTM standards like E3, E45, E112, E407, E562, and F312.

Metallographic Analysis Insights:

- Grain Size and Growth: Understanding grain structure resulting from processing.

- Intermetallic Phase Microstructures: Identifying carbide formation and chemical microsegregation.

- Defect Analysis: Examining microshrinkage, porosity, and inclusions.

- Surface Analysis: Observing graphite structures in cast irons, silicon structures in Al-Si alloys, and other material-specific features.

Contact Us

Feel free to contact us today to discuss your metallography concerns. We’re happy to work with you to devise a custom plan of action that effectively resolves your challenges. Contact us for more information. Our team looks forward to helping you with your metallographic analysis needs.