Comprehensive Interface Analysis

At Anderson Materials Evaluation, we specialize in interface analysis, interface characterization, and contamination testing at interfaces. We identify and characterize chemical interactions and contaminants at interfaces to ensure your materials’ integrity and performance.

Key Services:

- X-ray Photoelectron Spectroscopy Services (XPS/ESCA):

- Identify surface contamination.

- Analyze surface chemistry.

- High sensitivity with an 8 nm analysis depth.

- Verify clean surfaces and contamination thickness.

- FTIR Analysis (Infrared Spectroscopy):

- Identify organic and inorganic functional groups.

- Analyze how polymers break down at surfaces and interfaces.

- GC-MS Testing (Gas Chromatography – Mass Spectroscopy):

- Detect additives in plastics and elastomers that may cause bonding failures.

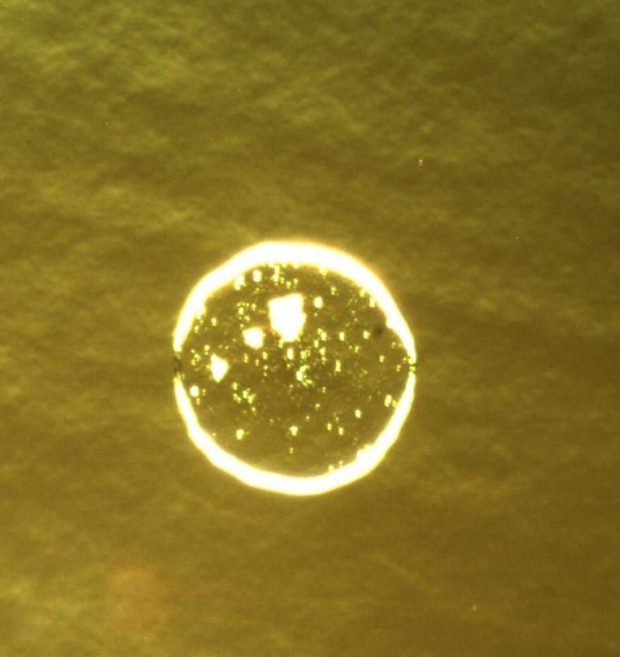

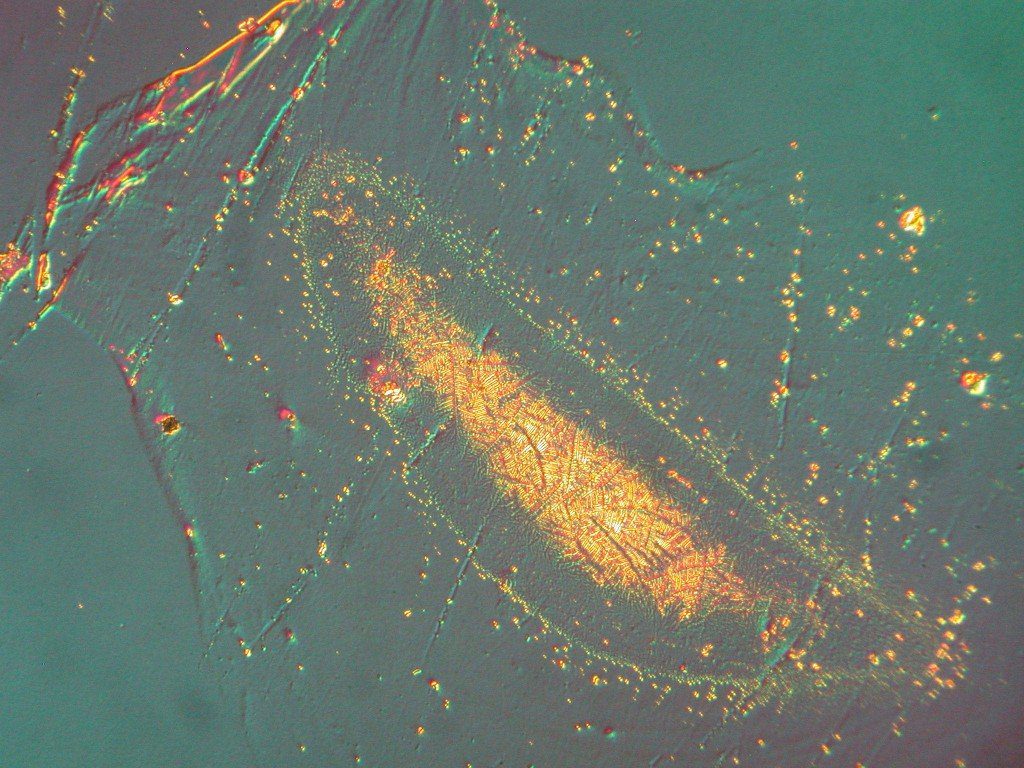

- Microscopic Examinations:

- Use SEM and Metallographic Microscopy for unwanted substances and deposits in surfaces.

- Perform profilometry, surface roughness, and topography analysis with Keyence/LIBS.

- Corrosion Testing:

- Evaluate coatings and protective films.

- Surface Cleaning Technique Evaluations:

- The advanced cleaning method CO2 Snow Jet Cleaning.

- The traditional and effective solvent-based cleaning.

- Microwave Plasma Cleaning for complicated surface treatments. We can also identify changes in surfaces due to plasma cleaning.

- We can test the cleaning effectiveness with analytical techniques.

- Effect of interfacial contamination on adhesion to the interface using pull tests.

Applications:

- Electronics contamination

- Packaging materials contamination

- Medical device contamination

- Composite materials and adhesive bonding

- Corrosion analysis and prevention

Interface Characterization

Interfaces play a crucial role in materials science, affecting adhesion, corrosion, and overall performance. Our services help determine the chemistry of surfaces, grain boundaries, and breaks. We analyze contamination and interfacial reactions to prevent failures and enhance material performance.

Contact Us for More Information

For more detailed information on our interface testing services and to discuss your specific needs, please visit our more detailed page on interface testing or our page on adhesion testing.

Explore our comprehensive interface analysis and interface chemistry solutions to ensure your materials meet the highest standards of performance and reliability. Contact us today to learn more and get started.