Inclusion Content in Steel – Qualifying Material Lots

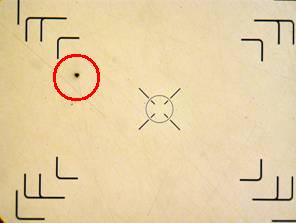

Anderson Materials examined the specimen in the image for inclusions. We took the specimen and prepared and evaluated it per ASTM Standard E 45 Method A.

Inclusions in Steel – Evaluation Process

- Preparation: We ground and polished the specimen as outlined in ASTM Standard E 3.

- Visual Survey: A visual survey was completed over 160 mm² (0.25 in²) of the surface is performed at 100x magnification in fields with an area of 0.50 mm² each.

- Rating: We rated the entire sample by its worst field for various potential inclusions, such as the “Type D Globular Oxide” heavy inclusion indicated by the circle.

Purpose

Anderson Materials Evaluation compared the worst fields to preset acceptance criteria. This evaluation can qualify bulk material lots before they are introduced into manufacturing processes.

Contact Us

If you have any questions or need further assistance with inclusion content evaluation or any other metallurgical analysis, please contact us. We are here to help you with your specific needs and ensure the highest quality in your materials.