Anderson Materials Evaluation offers expert hardness testing services for a variety of materials. Our specialized tests use durometers, which measures the resistance of materials to indentation. This is crucial for understanding the durability and performance of materials in different applications.

Durometer Hardness Testing

Durometers use a needle to press into the material surface, measuring the resistance and converting it into a hardness value. Tests are conducted in at least three different locations with a minimum material thickness of 6mm, and the average of these measurements is used to determine the overall hardness.

Types of Durometers

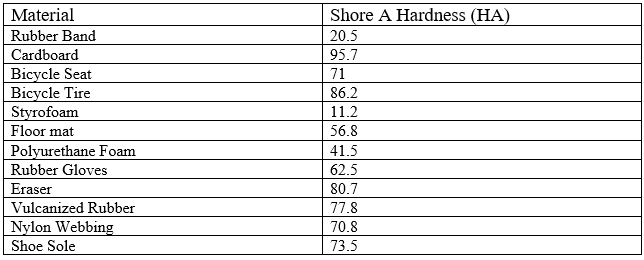

- Shore A Durometer: Ideal for softer materials such as rubber, polyester, leather, and wax. It measures hardness up to 100.

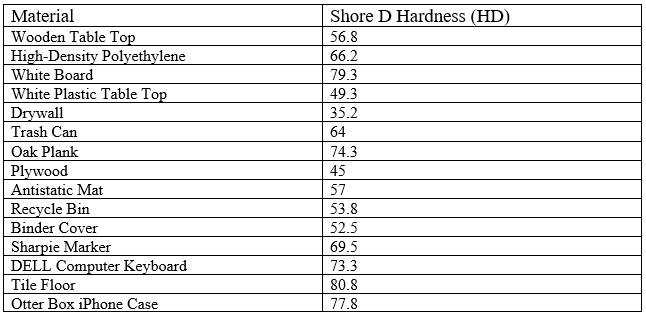

- Shore D Durometer: Suitable for harder materials like wood, hard rubber, plastics, and flooring. It is commonly used to measure high-density polyethylene.

Example Results for Various Materials

Our testing services provide accurate and reliable results for a variety of materials. Example tables of Shore A and Shore D durometer measurements illustrate our capabilities in assessing material hardness.

ASTM Testing Methods for Hardness Testing

- ASTM D2240: Standard Test Method for Rubber Property – Durometer Hardness.

- ASTM D3363: Standard Test Method for Film Hardness by Pencil Test, typically applied to paint or coatings on rigid substrates.

Contact Us

For more information about our hardness testing services and/or to discuss your specific testing needs, please contact us today. Our team is ready to assist you with precise and detailed material hardness analysis to help you and your materials analysis needs.