Our customer sourced large glass parts from China for outdoor use, expecting durability. Shortly after installation, discoloration and cracking appeared, prompting an investigation. The specified borosilicate glass type, known for UV resistance, was initially chosen.

Investigation and Analysis

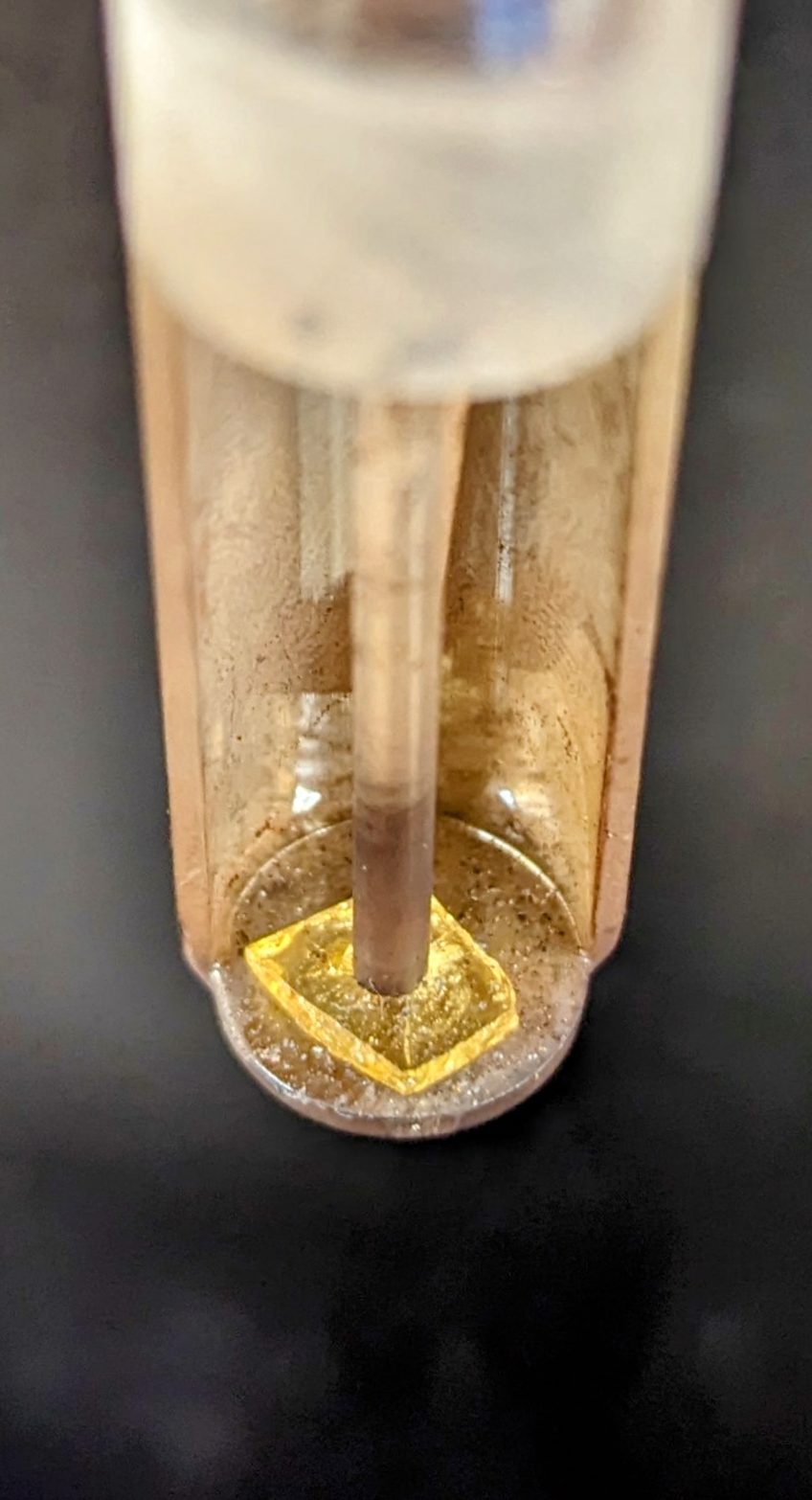

To understand the discoloration, we used X-ray Photoelectron Spectroscopy (XPS) to analyze elemental composition. Results were surprising. The Chinese glass had much lower boron, higher sodium, barium, and unexpected calcium. Potassium, chlorine, and zinc were also present, unlike the specified glass. Additionally, the Chinese glass lacked fluorine and had carbon-oxygen bonds not seen in the specified glass.

Further analysis revealed the specified borosilicate glass had lower coefficient of thermal expansion (CTE) than the Chinese glass. This difference caused occasional cracking due to mismatched thermal expansion.

Conclusion

This analysis highlighted composition differences and stressed the need for precise specifications to prevent material failures.

Our Services

We invite you to reach out to us to address any concerns you may have regarding your glass materials. We are eager to engage in a discussion about your specific challenges and explore tailored solutions to help you find and resolve the issue at hand. Your satisfaction and peace of mind are our top priorities, and we look forward to the opportunity to assist you effectively.