Anderson Materials Evaluation has extensive experience in glass analysis and the analysis of fiberglass materials. We have determined the composition of glass materials ranging from optical cables to lenses in surveillance equipment. We have examined glass for surface hardening and toughening as in safety glass. We have measured the hydroxyl concentration change with depth into a glass surface. We have measured the compressive layer thicknesses at the faces of tempered glass which has shattered. We determined the reason for UV color changes induced in glass samples. AME has investigated the cause of adhesive bonding failures to glass auto windows and to E-glass and S-glass fiberglass in composite materials. We have characterized glass surfaces with varying electrostatic properties.

Dr. Anderson determined that a high surface alkalinity caused adhesive bonding failure between glass microspheres and the foam insulation used in external fuel tanks for the Space Shuttle a few years before founding AME. We have analyzed the glass spheres in various samples of fly ash from coal-fired electric power plants. We have measured or detected many silane coupling agents on glass surfaces used to promote adhesive bonding. We have examined bullet-proof and explosion-resistant windows of glass bonded to polycarbonate layers. We have examined coatings on glass microscope slides used to adjust the hydrophobic or hydrophilic properties of the glass surfaces. We have analyzed endoscope lenses, car back-up lenses, contact eye lenses, and larger lens surfaces.

We have measured the thermal expansion or CTE of many glasses and graded thermal expansion glasses, including fiberglass tows. We have examined glass to metal and glass to ceramic seals. In our many glass analysis projects we have examined sands, silicas and silicates, and many silica gel materials. We have investigated silica gel adhesives used with biomedical devices in numerous applications. We have identified sizing agents on fiberglass. We have also identified the reason for spontaneous tempered plate glass shattering due to a phase transition in nickel sulfide (NiS) inclusions which causes a volume change in the inclusion. We have examined optical fibers for carbon inclusions and coatings on these fibers for scattering imperfections. In our glass analysis projects we have examined many anti-reflective or reflective coatings on glass to measure the thickness and purity of the multi-layered structures in the layers of the coatings. We have examined the effects of heat treatments and cleaning procedures on the optical coatings.

Glass Composition by WD-XRF Analysis

- Determines the quantitative composition for elements fluorine through uranium

- Provides very low detection limits, commonly from a few tens of ppm to less than 10 ppm for heavier elements

- Does not detect lithium, beryllium, and boron as XPS analysis does

Glass Analysis by XPS or ESCA Surface Analysis

- Quantitative elemental composition of a surface for all elements except hydrogen as-received or freshly fractured

- Surface chemistry after chemical exposure to treat surface for bonding or other surface treatment

- Silane coupling agent coverage on surface for adhesive bonding

- Anti-reflective coating analysis by depth profiling of elements

- Study leaching of glass which may leach Na, Ca, K, or B among other elements

- Measure profile of chemically-hardened glass such as potassium substitution for sodium

- Identify cause of etch-attack of glass

- Measure surface contamination

- Evaluate glass microspheres, frits, and fibers for adhesive bonding by examining for alkali surface chemistry

- Distinguish E and S fiberglass

- Characterize the chemistry of silicates and silica gels, which can be complex

- Analyze cause of failure of adhesive bonding to glass

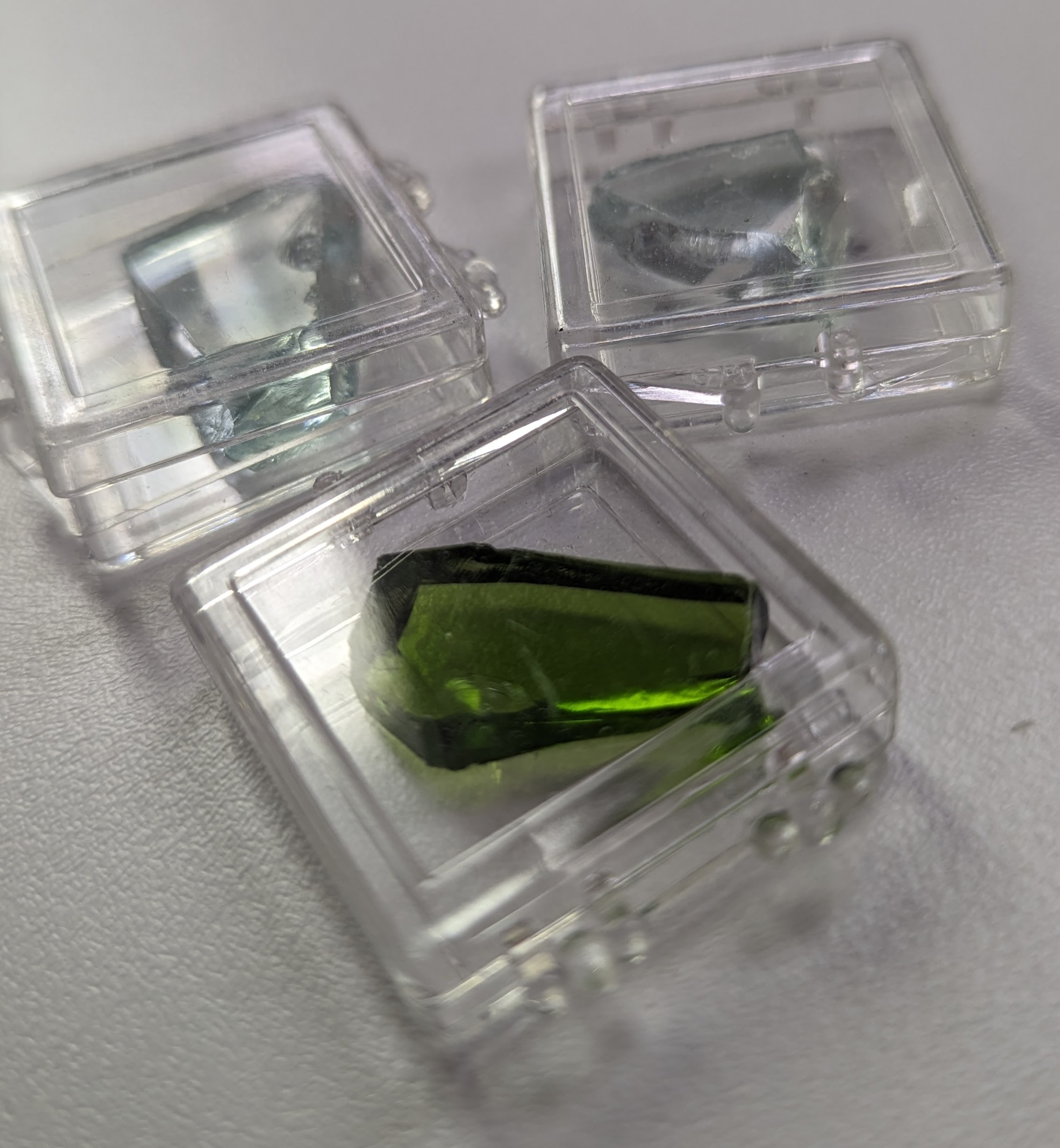

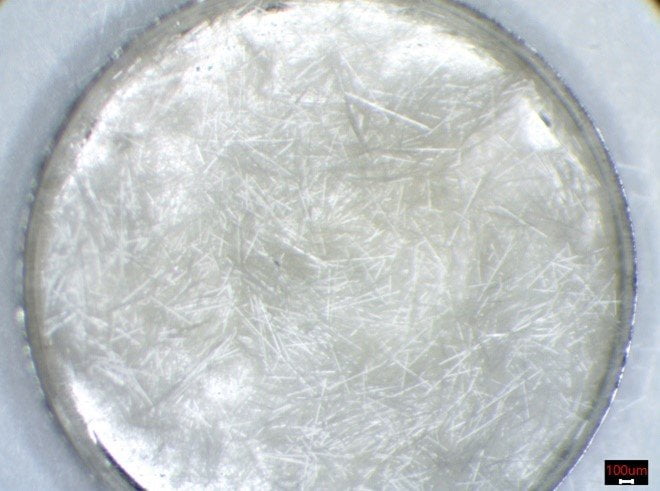

Microscopy (Optical and SEM) Analysis

- Locate inclusions, such as graphitic inclusions, common in “high-purity” quartz materials

- Measure the thickness of the compressive surface layer in tempered glass

- Examine anti-reflective coatings for uniformity and imperfections, including reaction zones between sub-stoichiometric layers

- Examine etching effects

- Find nickel sulfide spheres responsible for the spontaneous fracture of tempered glass

- Examine optical coupling interfaces for defects and contamination

- Cross-section analysis of optical couplers and glass encapsulated devices

Thermal Analysis

- TMA or Thermomechanical Analysis or Dilatometry:

- Measure thermal expansion

- Measure softening temperature under modest loads

- Measure the glass transition temperature

- Measure the melting temperature

- TGA or Thermogravimetry:

- Measure decomposition of silica gels and water weight loss

- Measure weight of fiberglass in FRP and PCB materials by decomposition or oxidation of resin

- Measure weight of silica and aluminosilicate particle fill in plastics, adhesives, paint, and sealants

- Measure weight of organic coatings on optical fibers or fiberglass

- DSC or Differential Scanning Calorimetry:

- Measure melting temperature

- Measure reaction energy of glass or silicate particles with adhesive, resin, or other fill particles

FTIR or Infrared Spectroscopy Analysis

- Identify organic coating on glass fibers

- Check organic coating uniformity on glass fibers

- Identify reflective organic films on glass window panes

- Examine adhesive bonds to rubber and elastomers

Laser-Induced Breakdown Spectroscopy (LIBS)

- Distinguish fiberglass fibers from polymer fibers quickly and easily while using the Keyence 3D optical microscope

- Quickly determine whether a glass has such elements as aluminum, calcium, sodium, lead, or boron at elevated concentrations

GC-MS or Gas Chromatography – Mass Spectroscopy Analysis:

- Identify organic coating materials such as sizings on glass fiber surfaces

- Identify and measure organic chemical residues from the surfaces of glass vessels or storage containers

- Identify and measure organic contaminants on the surfaces of glass fibers

- Compressive Strength

- Breaking Strength and Modulus of Rupture

ASTM Test Methods

- ASTM C1505 – Determination of Breaking Strength and Modulus of Rupture of Ceramic Tiles and Glass Tiles by Three-Point Loading

- ASTM C1666 – Standard Specification for Alkali Resistant (AR) Glass Fiber for GFRC and Fiber-Reinforced Concrete and Cement

- ASTM D578 – Standard Specification for Glass Fiber Strands

- ASTM D1577 – Standard Test Methods for Linear Density of Textile Fibers

- ASTM D2256 – Standard Test Method for the Tensile Properties of Yarns by the Single-Strand Method

- ASTM D2584 – Standard Test Method for Ignition Loss of Cured Reinforced Plastics

- ASTM D3800 – Standard Test Method for Density of High-Modulus Fibers

- ASTM D4963 – Standard Test Method for Ignition Loss of Fiber Glass Strands and Fabrics