Overview

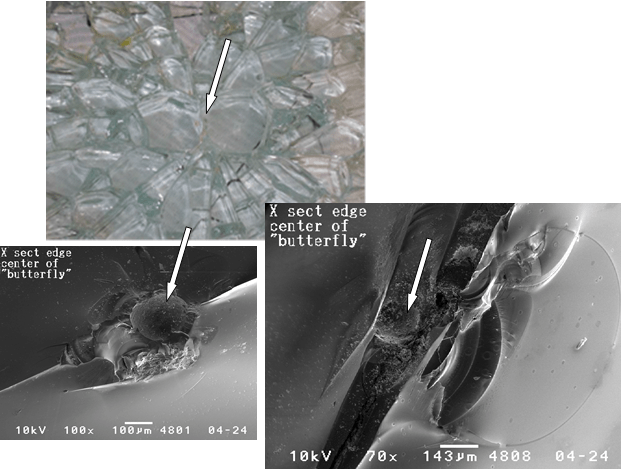

A tempered glass pane broke suddenly after approximately 30 years of service. The provided pane piece, shown in Figure 1, had the failure origin, known by the crack pattern growing out from two larger polygonal glass pieces forming a “butterfly” shape, typical of stress concentration at the origin point.

Analysis

Microscopic Examination:

SEM images of the butterfly break faces revealed brittle chipping around a nearly spherical nickel sulfide inclusion (pocket shown on the left, actual inclusion shown on the right).

Spontaneous Failure Causes:

Tempered glass often fails suddenly due to inclusions, typically nickel sulfides, formed from impurities during manufacturing. Nickel sulfide (NiS) exists in two phases:

- Alpha (α) Phase: Stable at higher temperatures (above 379°C).

- Beta (β) Phase: Stable at lower temperatures.

During the tempering process, we heat the glass into the α-NiS temperature range and rapidly quench it, creating surface compressive stress and interior tensile stress. This stress arrangement causes tempered glass to break into many small, rounded pieces rather than large, jagged ones. If NiS impurities are present, they can become trapped in the α-NiS structure, which is metastable below 379°C and can transition over time to the β-NiS phase. This transition increases the volume by up to 4%, building localized stresses that eventually lead to sudden catastrophic failure. The phase transition speed can be extremely slow and affected by thermal factors, such as sunlight.

Fracture Inspection:

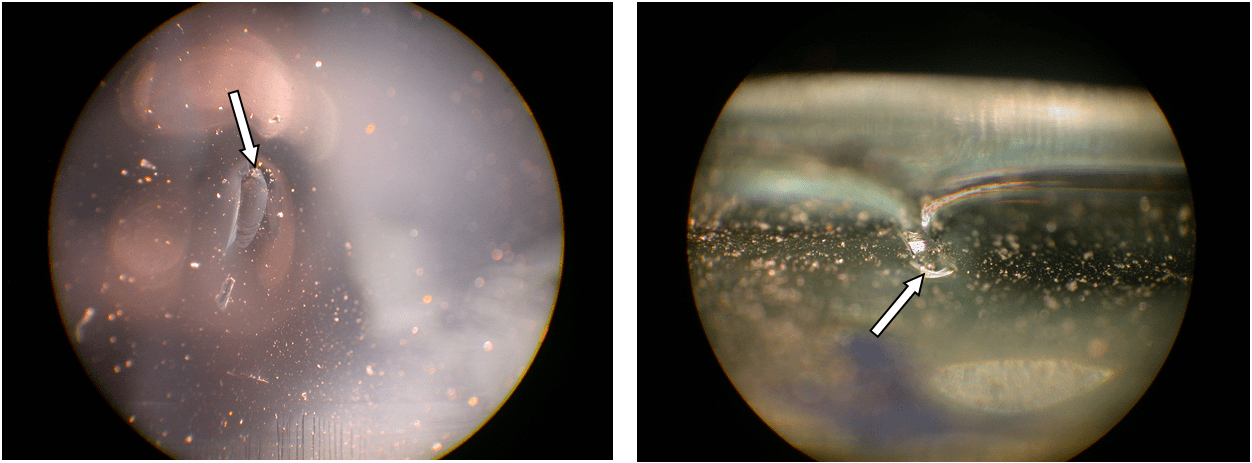

We took butterfly pieces and initially inspected them with optical microscopy, showing microscopic chip features halfway through the pane thickness, proving an inclusion was present. Figure 2 shows example images.

SEM/EDX Analysis:

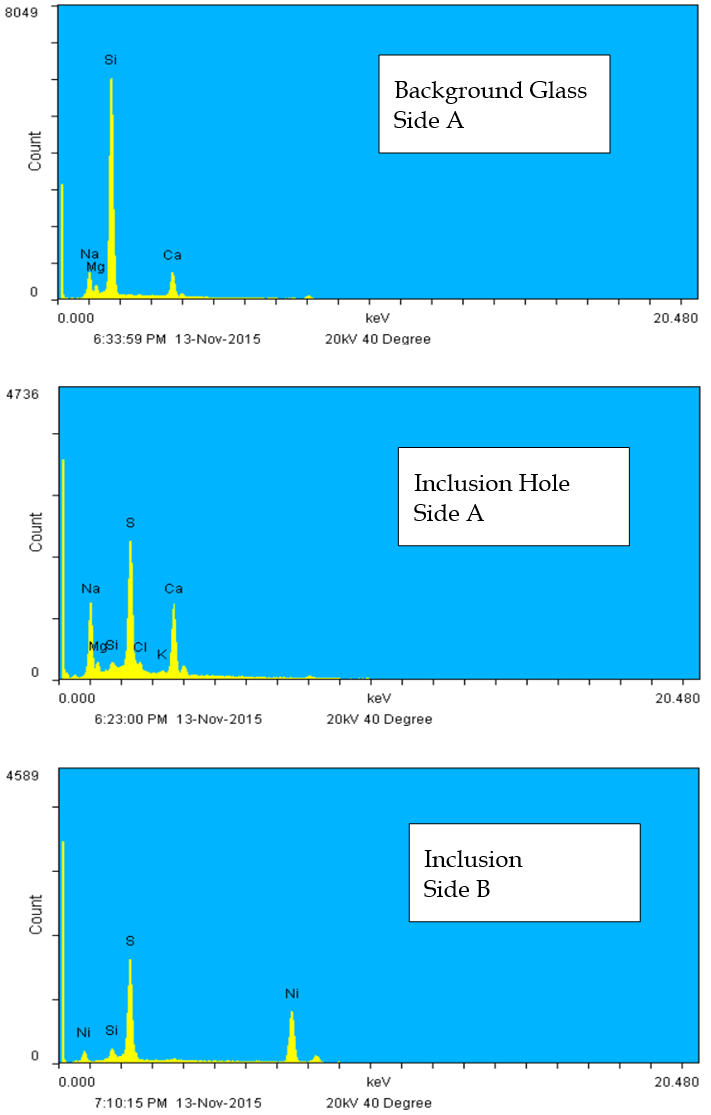

We examined the specimens using SEM/EDX. The SEM images in Figure 3 show the initial crack zone and origin. EDX identified the elliptical ball-like particle on “Side B” as the NiS inclusion. The EDX spectra in Figure 4 display the elemental compositions of the background glass, impurities at the inclusion/glass boundary (inclusion hole), and the inclusion itself. Only the inclusion contains Ni and S, with no detectable impurity elements in the glass body.

Finding the nickel sulfide inclusion at the fracture origin confirmed that impurities present during the glass pane’s creation caused this failure.

Figures

- Figure 1: Example images of microscopic chip features proving an inclusion was present in the glass.

- Figure 3:

- Top Row: Side A

- Bottom Row: Side B

- Left Column: Initial crack from the origin

- Upper Right: Hole left by the inclusion with other crystalline impurities (Side A)

- Lower Right: NiS inclusion (Side B)

- Black Squares: Positions where EDX spectra were collected

- EDX Spectra: Only the inclusion itself (Side B) contains levels of Ni that could be detected. The surface of the hole on Side A shows glass composition elements with reduced Si concentration. We found additional S and other trace impurities as well.

Conclusion

The sudden breaking of the tempered glass window was caused by a nickel sulfide inclusion, an impurity present in the glass at the time of creation. This inclusion led to stress over time, in one location, resulting in the unexpected failure after three decades of service.

A tempered glass pane was reported to have broke without warning after approximately 30 years of service. The portion of the pane provided for analysis, shown in Figure 1, included the origin of the failure which was identifiable by the crack pattern moving out from two rather larger polygonal glass pieces forming a shape frequently referred to as a “butterfly.” This pattern is consistent with a stress concentration at the origin point.

Contact us today to discuss your materials testing needs.