Comprehensive DSC Analysis Services

At Anderson Materials Evaluation, we specialize in DSC Analysis Services, providing crucial insights into the thermal properties of materials. Our state-of-the-art equipment and expert analysis ensure reliable results for a wide range of applications, including dsc plastic analysis, glass transition temperature testing, and crystallization temperature testing. For more detailed information, please visit our In-Depth DSC Analysis page.

What is DSC Analysis?

DSC analysis, or Differential Scanning Calorimetry, measures the energy absorbed or released by a sample during heating or cooling. This technique provides quantitative and qualitative data on various thermal events, including melting temperature, heat of fusion, latent heat of melting, reaction energy and temperature, glass transition temperature, crystalline phase transition temperature and energy, and specific heat capacity.

Why Choose Our DSC Testing Services?

Our DSC testing services are designed to cater to various industries and materials. We ensure the highest quality of results by using advanced equipment and adhering to strict protocols. Here’s why you should choose Anderson Materials Evaluation for your DSC analysis needs:

- Precision and Accuracy: Our DSC equipment boasts sensitivity of 6 μW/cm, with precise temperature control from -120°C to 725°C. We also have access to high-temperature DSC/DTA instruments for measurements up to 1500°C.

- Versatile Sample Handling: We can analyze samples in various forms, including plugs, films, powders, or fibers, using different types of pans such as Al, Cu, Au, Pt, alumina, and graphite.

- Controlled Atmospheres: We conduct analyses under controlled atmospheres, including nitrogen, air, oxygen, argon, and vacuum, ensuring optimal conditions for accurate measurements.

Applications of Our DSC Analysis Services

Our DSC analysis services have broad applications across numerous industries. Here are some key applications:

- Polymers and Plastics: Determine melting behavior, glass transition temperatures, crystalline phase transitions, and identify contamination in polymeric materials.

- Metals and Alloys: Measure melting temperatures, heat of fusion, phase transition temperatures, and exothermic energies in metal alloys and intermetallic compounds.

- Pharmaceuticals and Foods: Analyze denaturation temperatures, oxidative induction periods, and specific heat capacities.

- Adhesives and Sealants: Evaluate exothermic energies of polymer cures, ensuring proper application and durability.

- Shape-Memory Alloys: Identify transformation temperatures and analyze hysteresis between heating and cooling cycles.

Illustrative Examples of DSC Testing

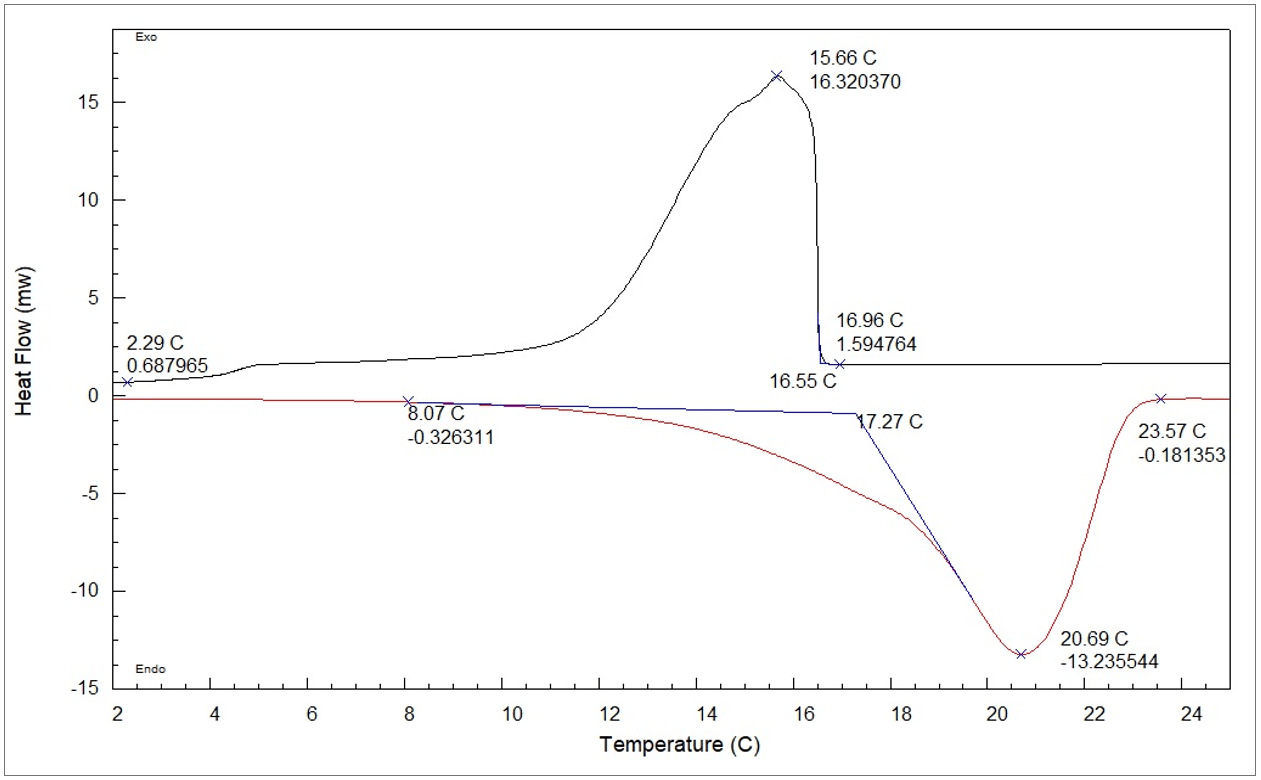

Example 1: Transformation Temperatures of a Shape Memory Alloy

We analyzed a Cu-Al-Ni alloy shape memory material, identifying martensite to austenite transformations upon heating. The DSC plot revealed distinct endotherms and exotherms, demonstrating the material’s thermal behavior.

Example 2: Epoxy Mixture Characteristics

Our DSC testing compared different resin to hardener ratios in epoxy mixtures. The results highlighted variations in endothermic peak temperatures, essential for quality control in epoxy production.

Example 3: Phase Transition of a Bio-Based Material

We identified precise phase change temperatures in a bio-based material using DSC analysis. The data revealed multiple regions in heating and cooling cycles, indicating material heterogeneity.

ASTM Standards for DSC Testing

We adhere to the following ASTM standards in our DSC analysis:

- ASTM D3417: Enthalpies of Fusion and Crystallization of Polymers by DSC

- ASTM D3418: Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by DSC

- ASTM D3895: Oxidative-Induction Time of Polyolefins by DSC

- ASTM E793: Enthalpies of Fusion and Crystallization by DSC

- ASTM E794: Melting and Crystallization by DSC

- ASTM E928: Determination of Purity by DSC

- ASTM E1269: Determining Specific Heat Capacity by DSC

- ASTM E1356: Glass Transition Temperatures by DSC

- ASTM E2160: Heat of Thermally Reactive Materials by DSC

Contact Us for Expert DSC Testing Services

For detailed and reliable DSC testing services, trust Anderson Materials Evaluation. To discuss your project requirements or to learn more about our DSC analysis capabilities, please contact us at contactus@andersonmaterials.com, complete a contact form on our Contact Us page, or call us.

Discover the full potential of your materials with our expert DSC analysis services. Visit our In-Depth DSC Analysis page for more information.