Contact angle measurements are a technique for studying and measuring properties of the liquid — solid interface. The wetting properties of a surface by a particular liquid can be characterized by measuring the contact angle of a small droplet of the liquid on the surface. By using several liquids with differing surface tensions (such as water, ethylene glycol, and diiodomethane), the surface tension or surface energy of the surface to which they are applied can be determined. We can measure the polar and the dispersive surface tension values at liquid-solid interfaces. We can also follow changes in the droplet- interface dynamic behavior with time. These changes result from chemical alteration of the solid surface with time of exposure to the liquid.

The surface energy may be important because one may want a liquid to wet or adhere to the surface or one may want it to be repelled by the surface. The wetting of the surface by an adhesive or by a coating material will be affected by the surface energy. Or, the measurement of the surface energy may just be used as a good indicator of having achieved a desired surface chemistry upon processing a material or having given it a surface treatment. The measurement of the contact angle is often a good test of the cleanliness of a surface as well since the contaminated surface may wet more or less easily than the clean surface does.

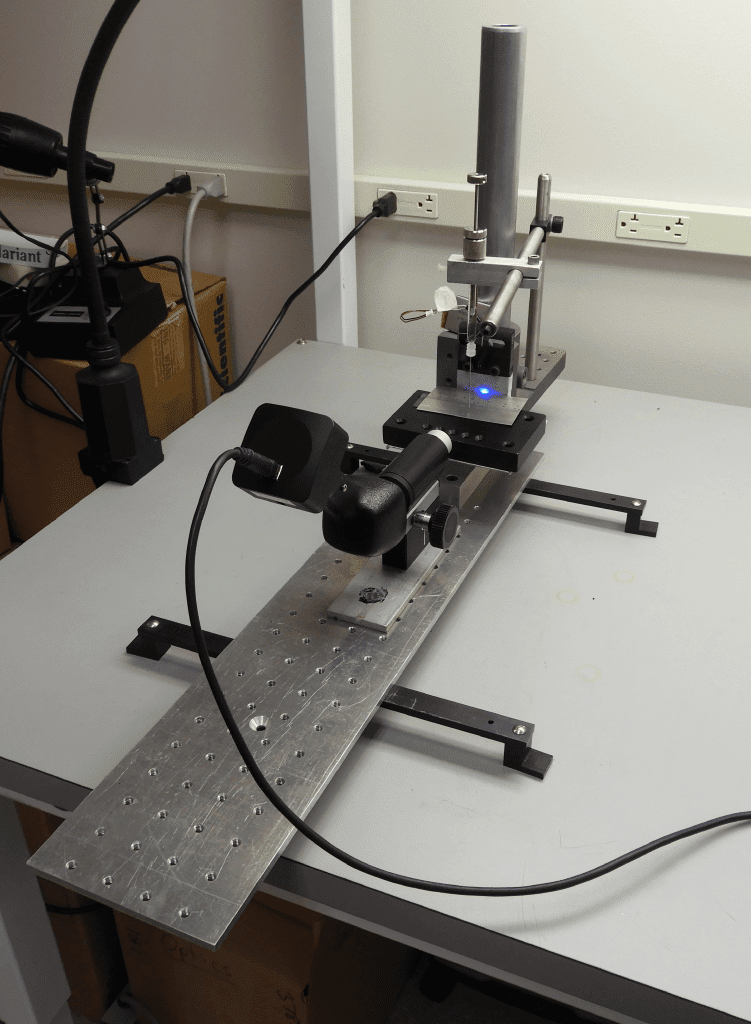

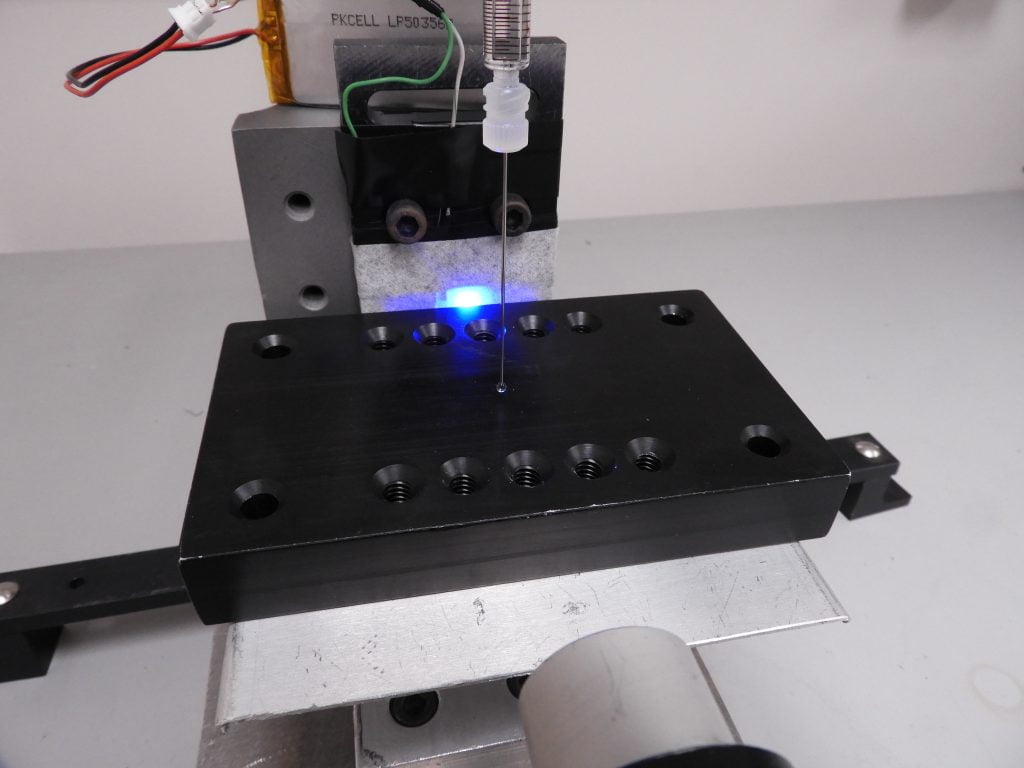

Liquid droplets are applied to the surface using a syringe. The small droplet is observed using a closeup camera. The image of the droplet is then analyzed by computer software from points marked along the droplet-air interface to calculate the contact angle at the droplet-surface interface. These measurements are made by Dr. Shreyasi Sengupta. We also make dynamic measurements that observe the interaction between the liquid droplet and a surface at a rate of 60 frames a second.

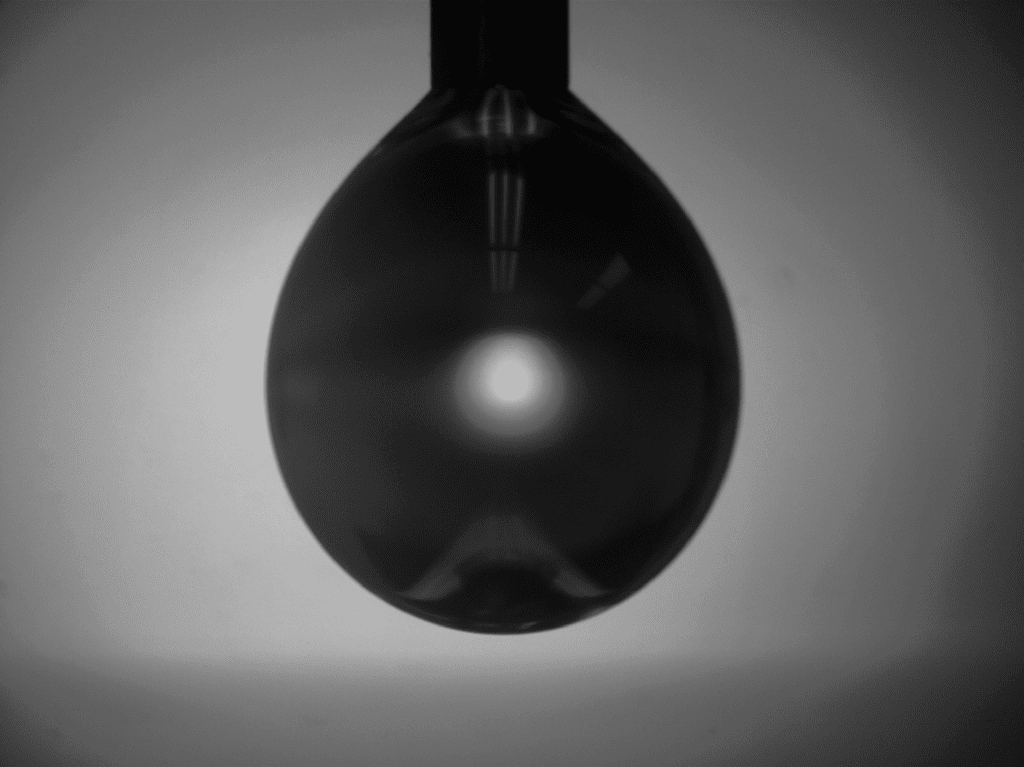

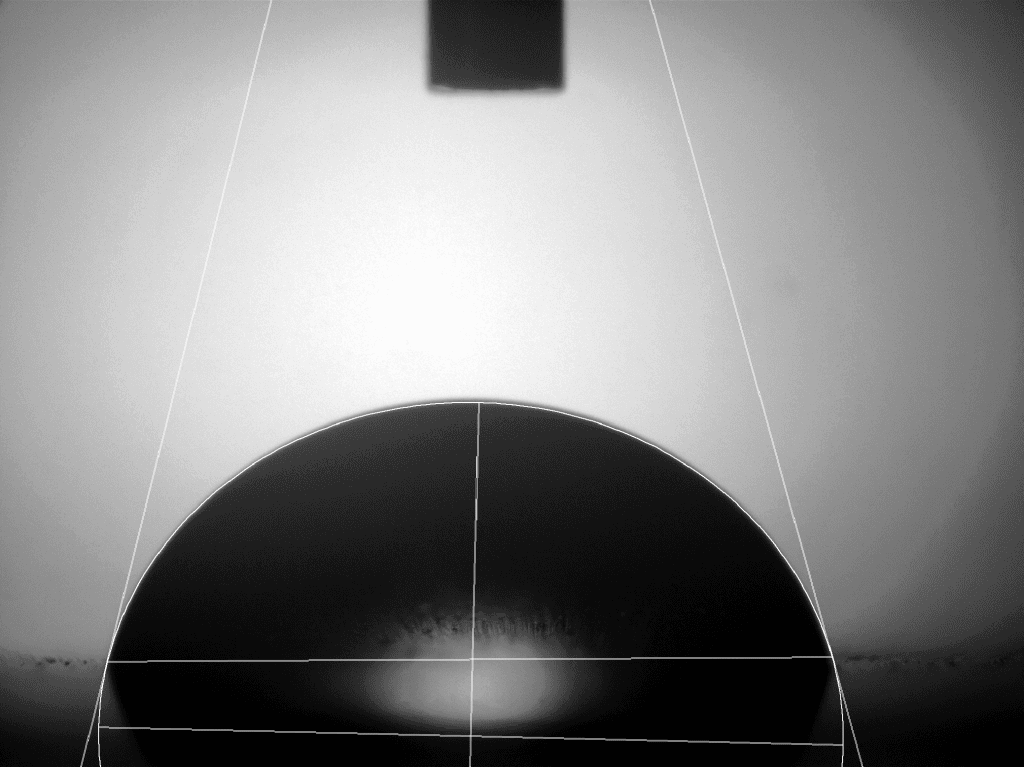

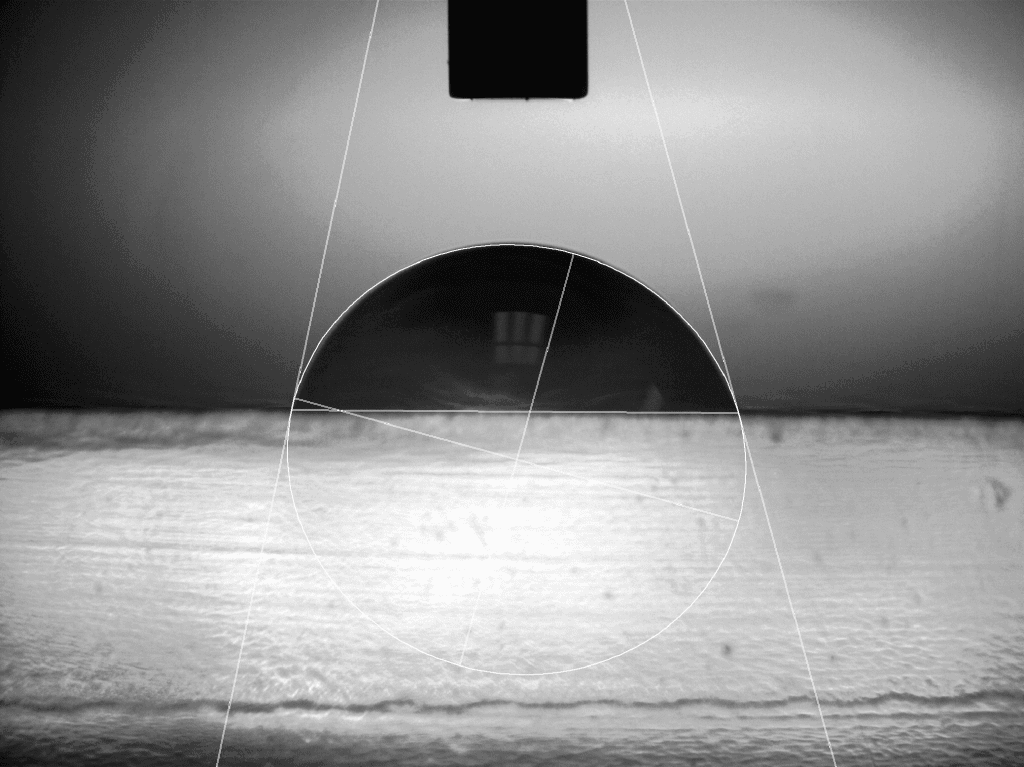

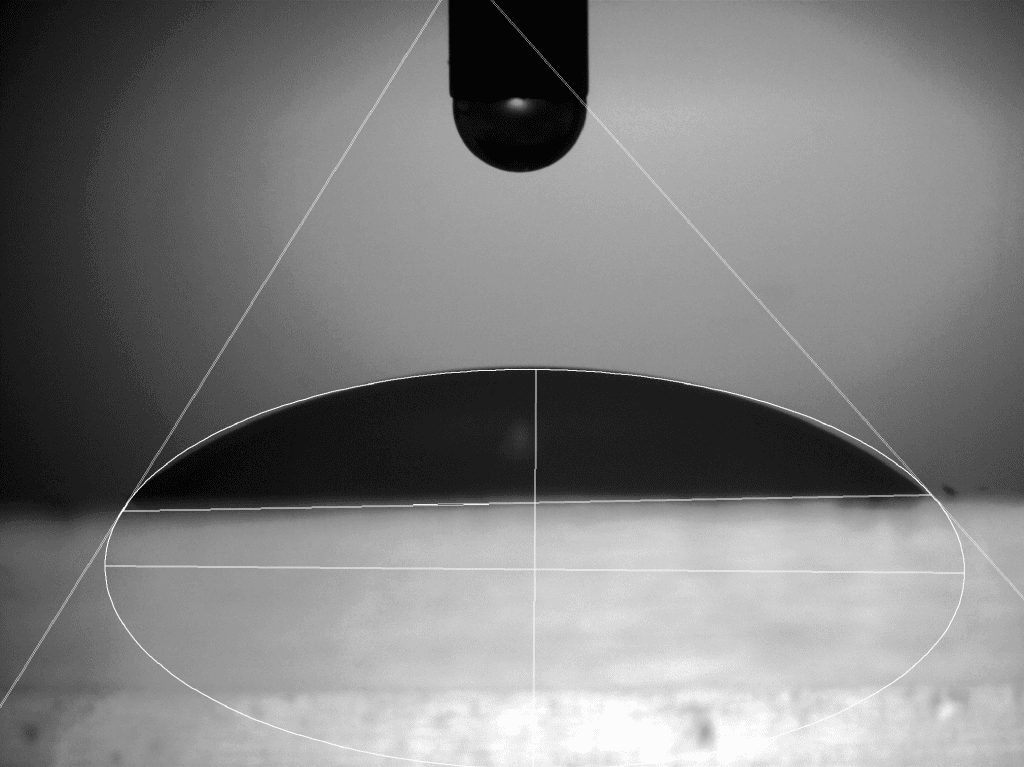

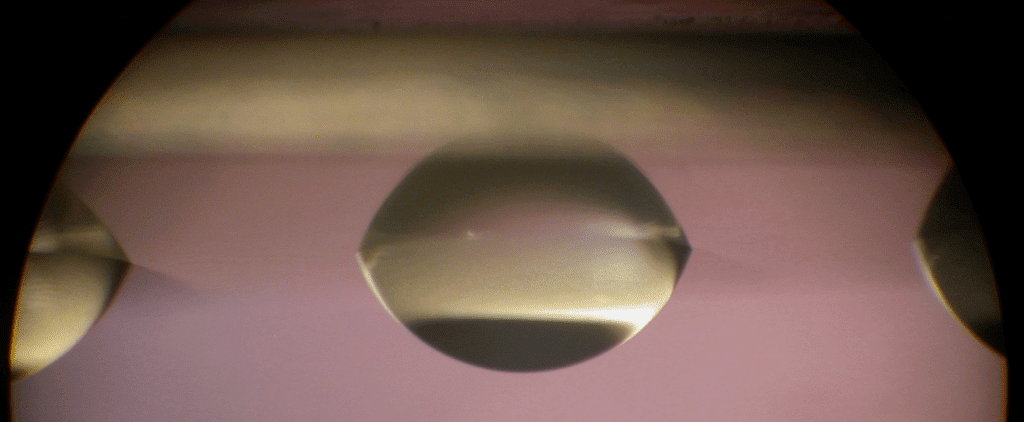

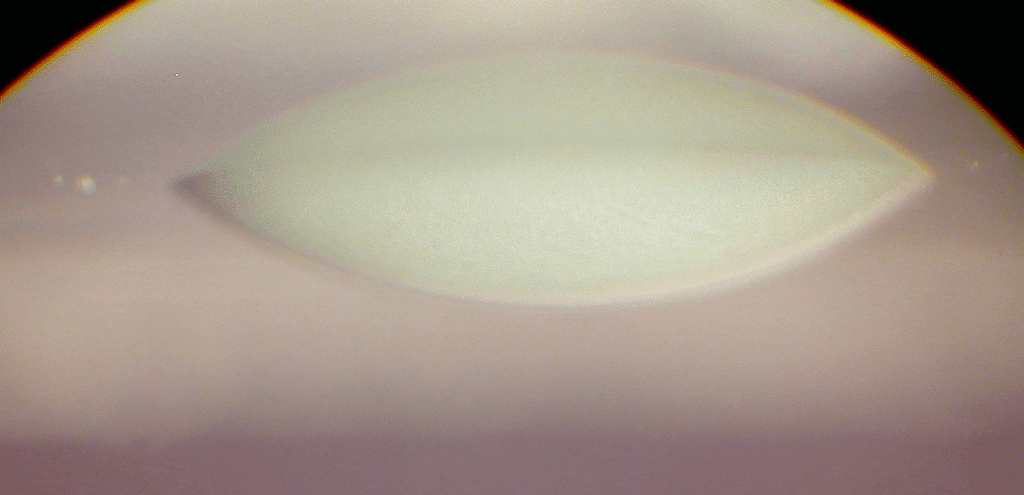

Fig. 3. The top image shows the water droplet formed at the end of the flat bottomed syringe. The next image shows the water-solid interface of a hydrophobic coating on a metal foil with a contact angle of 75 degrees. The third image is of a water – plastic interface which is also hydrophobic with a contact angle of 76 degrees. The last image is water on a glass slide which is hydrophilic. The contact angle is 53 degrees.

Example of a Contact Angle Measurement

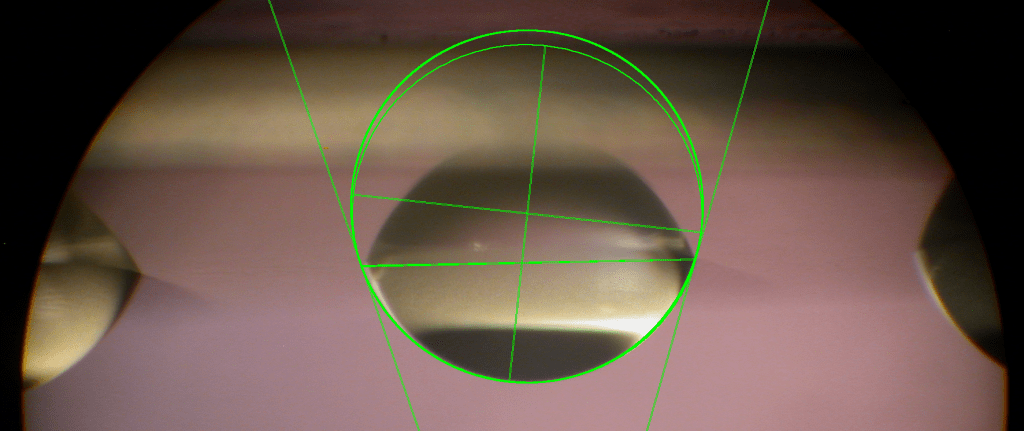

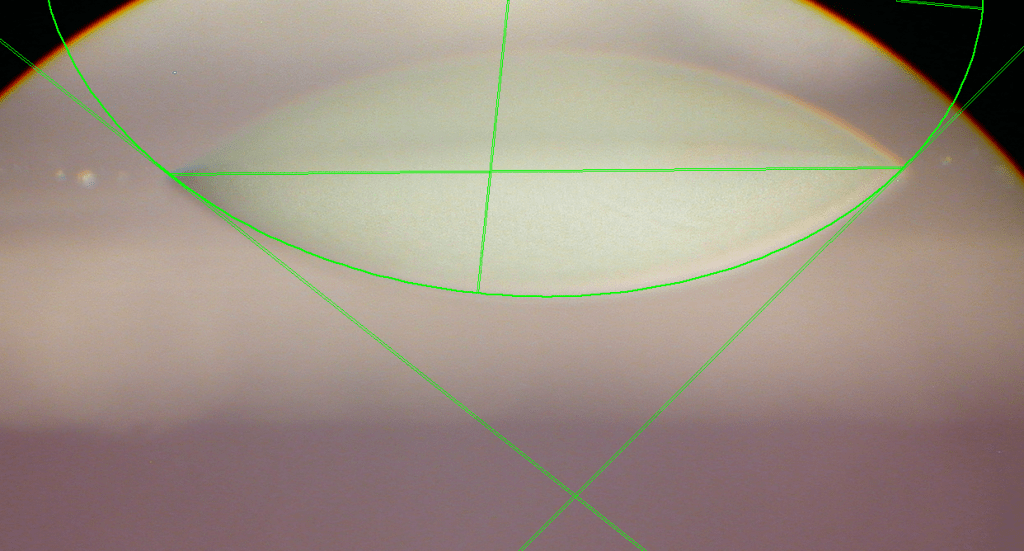

These images illustrate the contact angle measurement of both water droplets and a plasticizer. The process involves placing a liquid on a desired surface in order to examine how the substance interacts with the material, such as treated metal. Figure 1, an image of water, demonstrates a high contact angle caused by the surface’s hydrophobic properties, whereas Figure 2, an image of the plasticizer droplet, shows stronger interaction with the surface or a greater ability to wet the surface. This is seen in its low contact angle and shallow profile. The surface is said to have a lower surface energy with respect to the plasticizer than with respect to water.

The next two images were taken after the contact angle measurement had been completed. The diagonal green lines are tangent to the three phase contact points, where the liquid, surface, and air meet on the edge of the drop, while the horizontal line shows the surface plane of the solid material. Both a circle fitting method and ellipse fitting method are displayed, which connect points along the surface of the water droplet before making calculations.

ASTM Standard Test Methods:

ASTM D7490-13 Standard Test Method for Measurement of the Surface Tension of Solid Coatings, Substrates and Pigments Using Contact Angle Measurements

ASTM D5946 – 17 Standard Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements

Contact Shreyasi Sengupta, Ph.D., Shreyasi@andersonmaterials.com to discuss your contact angle measurement needs.