At Anderson Materials Evaluation, we specialize in contact angle measurements to assess surface wettability and surface energy. These analyses are crucial for a wide range of applications, from ensuring proper adhesion in coatings and adhesives to verifying the cleanliness and treatment effectiveness of surfaces.

This is a summary of our capabilities and test methods. For a more in depth summary, please check out our page “Contact Angle Measurements – An In Depth Look“.

Our Contact Angle Measurement Services

Precision Analysis for Critical Insights

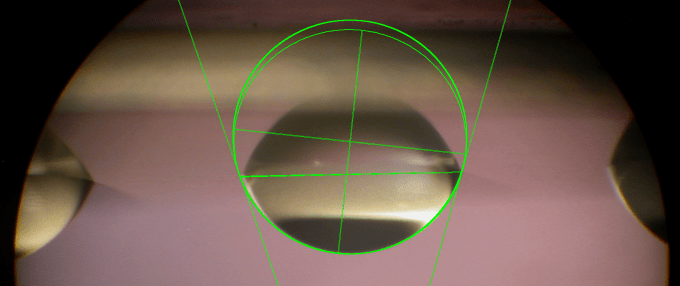

Our contact angle measurements provide detailed insights into the liquid-solid interface. By placing a small droplet of liquid on a surface and analyzing the resulting contact angle, we can determine the surface’s wettability and energy properties. This information is essential for optimizing material performance and ensuring successful application in various industries.

Comprehensive Surface Energy Evaluation

Using different liquids such as water, ethylene glycol, and diiodomethane, we measure both polar and dispersive surface tension values. This comprehensive evaluation helps in:

- Adhesion Optimization: Ensuring coatings and adhesives bond effectively.

- Surface Treatment Verification: Confirming that treatments have achieved the desired surface chemistry.

- Cleanliness Testing: Detecting contamination that might affect surface properties.

Dynamic Measurement Capabilities

Our contact angle instrumentation captures the interaction between liquid droplets and surfaces at 60 frames per second, allowing us to monitor dynamic changes in surface properties over time. This capability is vital for understanding how materials behave under different conditions and over extended periods.

Real-World Applications

Ensuring Adhesion and Coating Performance

The surface energy of materials directly impacts the performance of adhesives and coatings. Our contact angle measurements help manufacturers select the best materials and processes to achieve optimal adhesion and durability.

Verifying Surface Treatments

Surface treatments like corona treatment or plasma treatment can significantly alter surface properties. By measuring contact angles before and after treatment, we ensure that the desired modifications have been successfully implemented.

Cleanliness and Quality Control

In industries where surface cleanliness is critical, such as semiconductor manufacturing or biomedical device production, our contact angle measurements provide a reliable test for verifying that surfaces are free from contaminants.

Advanced Analytical Techniques

State-of-the-Art Equipment

We use a high-precision syringe to apply liquid droplets, and a microscope with camera captures detailed images. These images are analyzed using sophisticated software to calculate contact angles with high accuracy.

Expert Analysis

Dr. Shreyasi Sengupta leads our contact angle measurement services, bringing extensive expertise to every analysis. Our team is dedicated to providing accurate and insightful data to support your material evaluation needs.

ASTM Standard Compliance

Our methods adhere to the following ASTM standards:

- ASTM D7490-13: Measurement of Surface Tension of Solid Coatings, Substrates, and Pigments.

- ASTM D5946-17: Testing Corona-Treated Polymer Films Using Water Contact Angle Measurements.

Contact Us

Ready to optimize your materials’ performance with precise contact angle measurements? Contact Dr. Shreyasi Sengupta for expert analysis and consultation at Shreyasi@andersonmaterials.com.