Composite materials analysis at Anderson Materials Evaluation involves a range of techniques to accurately characterize materials and their interfaces. These analyses are essential for understanding the properties and performance of composite materials, commonly used in engineering applications.

This is a summary of our capabilities. If you would like to read a more detailed list of our capabilities, please look at our page “Composite Materials Analysis – An In Depth Look“.

Key Analytical Techniques:

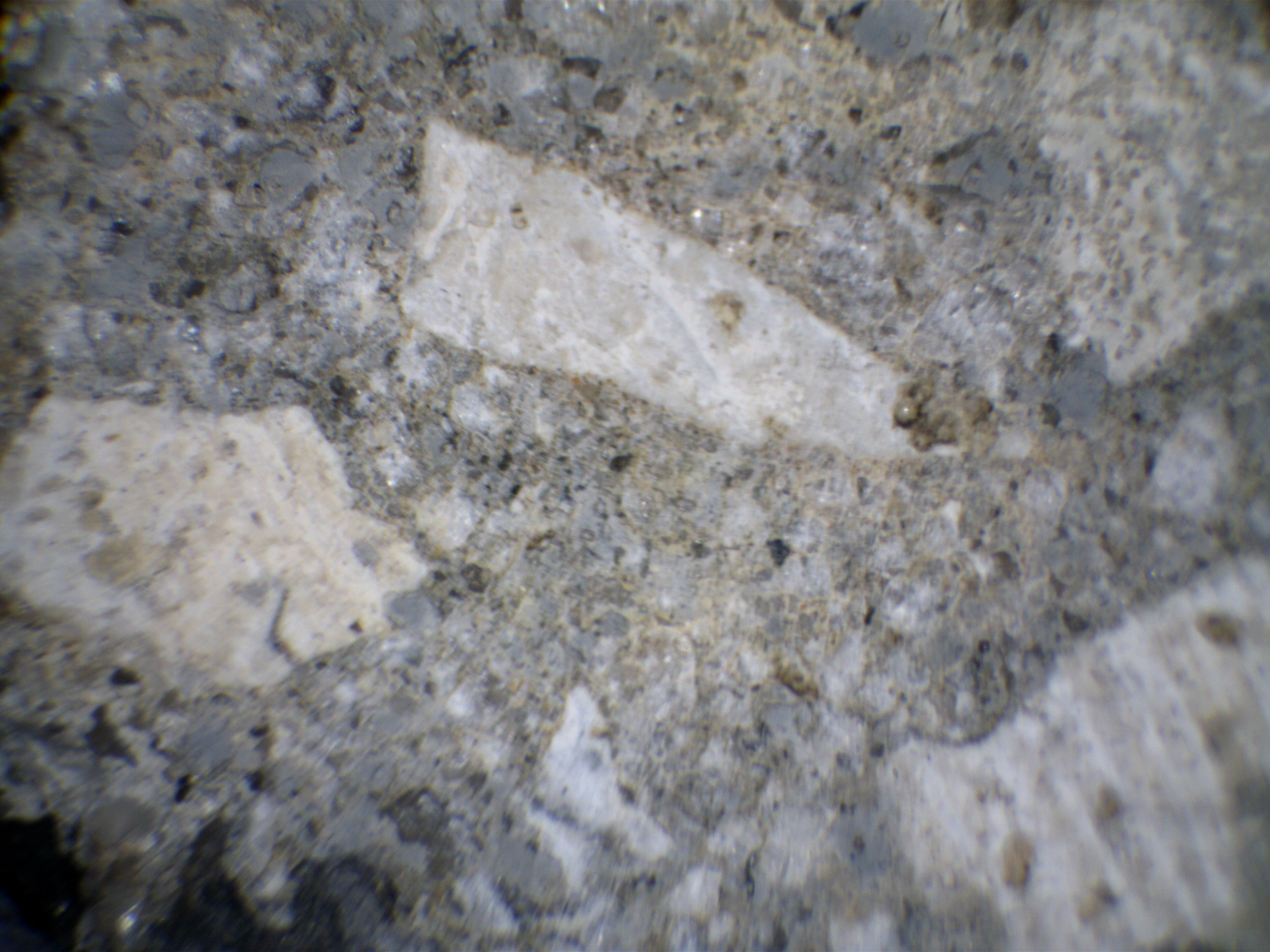

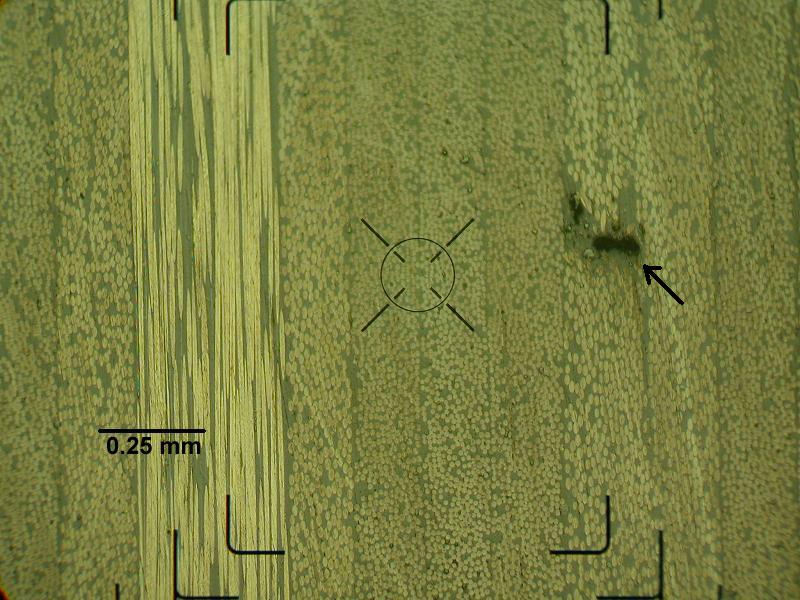

- Cross Section Microscopy Analysis with Inspection Microscope, Metallographic Microscope, Keyence 3D Digital Microscope, or SEM: Detect voids, measure layer thickness, and assess ply orientation in fiber-reinforced composites.

- Thermogravimetric Analysis (TGA): Measure fill materials’ weight, water content, and VOC emissions, and determine the temperature at which water is released.

- Thermomechanical Analysis (TMA): Evaluate thermal expansion, softening temperatures, and swelling characteristics.

- Differential Scanning Calorimetry (DSC): Assess glass transition temperature, degree of cure, and phase changes.

- FTIR Analysis: Identify organic resins and detect surface coatings.

- Gas Chromatography – Mass Spectroscopy (GC-MS): Analyze organic chemicals in resin and on fiber surfaces.

- Wavelength Dispersive X-ray Fluorescence (WD-XRF): Quickly determine the composition of inorganic fillers.

- X-ray Photoelectron Spectroscopy (XPS): Analyze polymer matrix composition, surface contamination, and interphase chemistry.

- X-ray Diffraction Analysis (XRD): Identify crystalline phases of fillers and the semi-crystalline structure of polymers.

- Mechanical Testing: Evaluate tensile strength, elasticity, and bending characteristics.

- Thermal Conductivity Measurements

- Density and Porosity Measurements

- Dielectric Measurements

Applications of Composite Materials:

Composite materials include polymer resins embedded with fibers, particles, or whiskers. Common examples include:

- Fiberglass Epoxy Composites

- Polymer-Based Composites: Polyimide, polysulfone, polyester, vinyl ester, polyurethane resins.

- Reinforcing Materials: E-glass, S-glass, carbon fibers, aramid fibers, metal wires.

- Fillers: Graphite, silicon carbide, aluminum oxide, silicon nitride, metal oxides.

- Adhesives and Sealants: Filled with silica, alumina, calcium carbonate, and other particles.

- Construction Materials: Concrete, mortars, wood, and bone.

Understanding the chemistry at interfaces and the behavior of fillers in the resin matrix is crucial for optimizing composite materials’ properties. Our expertise and advanced analytical tools enable us to provide thorough composite materials analysis, crucial for innovative product development and quality assurance.