At Anderson Materials Evaluation, Inc., we specialize in comprehensive ceramic materials analysis, using advanced techniques to provide accurate and reliable results.

For more in depth information on our ceramic testing abilities, please check out our original page on Ceramic Testing – An In Depth Look.

Overview of Ceramic Materials

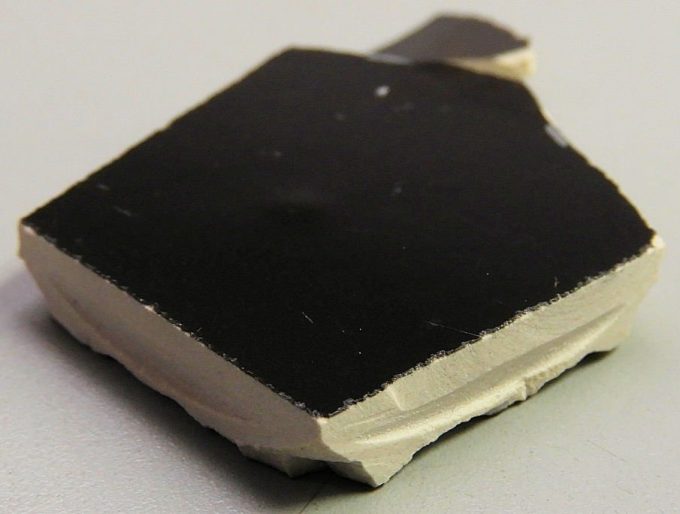

Ceramic materials are typically formed by processing inorganic particles under high pressure and temperature. Surface chemistry plays a crucial role in sintering, and binding materials are often added to enhance bonding. Brittle ceramics tend to fracture along particle interfaces, which can be investigated using X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDX).

Key Analytical Techniques for Ceramic Testing

Thermal Mechanical Analysis (TMA)

- Thermal Expansion Rates: Measure as a function of temperature.

- Shrinkage Measurement: Evaluate up to 800°C.

- Phase Transition Temperatures: Determine below 800°C.

Thermogravimetric Analysis (TGA)

- Weight Changes: Assess binder loss up to 1000°C.

- Outgassing: Evaluate during heating.

- Absorbed Water: Measure due to porosity up to 1000°C.

Microscopy (SEM, Optical, Keyence 3D)

- Fracture Surface Imaging: Determine particle sizes and binder residues.

- Cross-Section Analysis: Evaluate cracks and voids.

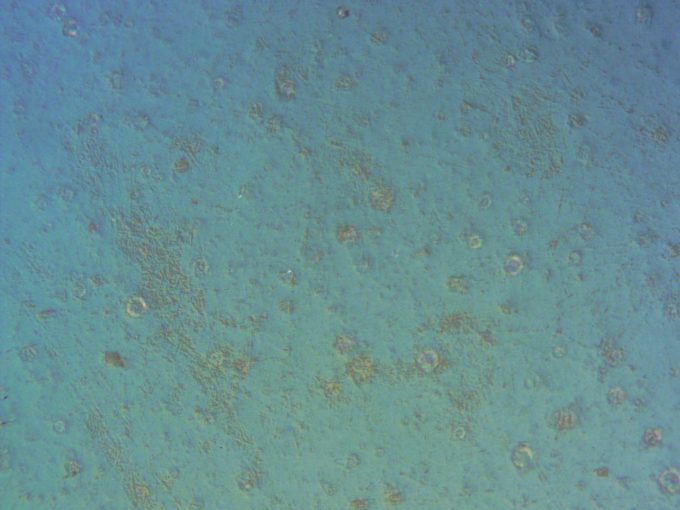

- Surface Examination: Detect defects and measure roughness.

X-ray Fluorescence (XRF) Spectrometry

- Elemental Composition: Determine and detect impurities up to 2 mm depth.

Laser-Induced Breakdown Spectroscopy (LIBS)

- Composition Analysis: Quickly assess ceramic materials.

- Small Area Analysis: Suitable for areas too small for XRF.

X-ray Photoelectron Spectroscopy (XPS) Analysis

- Surface Analysis: Measure elements to 20 nm depth.

- Deeper Analysis: Use argon ion etching.

- Contamination Analysis: Check surface and fracture surface chemistry.

Additional Testing Techniques

- X-ray Diffraction (XRD): Identify crystalline phases.

- Energy Dispersive X-ray (EDX) Analysis: Semi-quantitative elemental analysis.

- Infrared Spectroscopy (FTIR): Assess organic binder chemistry and contaminants.

- Thermal Conductivity measurements

- Density and Porosity measurements

- Compression Strength measurement

- Gas Chromatography – Mass Spectroscopy (GC-MS): Measure volatile contaminants prior to sintering or glazing.

ASTM Standards for Ceramic Materials Analysis

- ASTM C20: Porosity, water absorption, specific gravity, and density of refractory bricks.

- ASTM C773: Compressive strength of fired whiteware materials.

Case Histories on Ceramic Materials Analysis

- Ceramic Powder Identification on Floor Tile

- Cracking and Yellowing Cubic Zirconia Ceramic

- Defective Ceramic Floor Tile Glaze

- Lead in Ceramic Dinner Plate – Safety Hazard Evaluation

- Roughness and Appearance of Floor Tile Variance

- Silicon Nitride Ceramic Analysis

Contact Us

For expert ceramic materials analysis, contact Anderson Materials Evaluation, Inc. today. Our skilled team is ready to assist with your specific needs.