Humans have been using adhesives for at least 119,000 years. Initially, adhesives were primarily utilized to hold different materials together; however, they can also fail under certain conditions. Therefore, modern laboratory testing tools are essential as they help identify surface treatments, contaminants, and moving components that can either improve or compromise adhesion at interfaces. Moreover, Anderson Materials Evaluation (AME) has conducted hundreds of adhesion tests to investigate adhesive bond problems thoroughly. Additionally, our silicone collection kits have proven invaluable, enabling companies to monitor their equipment and facilities for contamination from silicones, fluorocarbons, and hydrocarbons.

Adhesion Testing Case Histories

Solving a Polymer Sealing Problem with XPS Analysis

Adhesive failure analysis and adhesion testing are among our specialized capabilities. Using such advanced tools as XPS surface analysis, contact angle measurements, FTIR, GC-MS, SEM, and optical microscopy, we can determine the causes of adhesive bonding failures, often resulting from very thin layers of contamination at interfaces. Furthermore, we can measure the strength of adhesive bonds through our mechanical testing capabilities, ensuring a comprehensive evaluation of adhesive performance.

Types of Adhesive Bonding Failures

- Cohesive Failures: Failure occurs in the bulk layer of the adhesive or adherends (material being bonded), usually the desired mode of failure.

- Adhesive Failures: Occur at the interface between the adhesive and the adherend, wanted in cases like temporary notes or protective films.

Silicone Contamination Detection

Silicones, especially dimethyl siloxane, can cause adhesive failures seen only with XPS. Our silicone contamination collection kits detect and measure silicone and other contaminants in facilities with greater sensitivity than FTIR or Soxhlet extraction methods. The limit for poly(dimethyl siloxane) is about 0.007 mg/sq.ft. or about 0.08 mg per square meter. Significant adhesive bond strength loss often occurs at about 15 times these concentrations. These kits also measure other contaminants which are airborne or found on surfaces in facilities.

Complexities in Adhesive Bonding Failures

Adhesive bonding failures can be complex, with failure caused by water, heat, radiation, or migration of additives. Interfacial failures might result from excessive hydration, alkaline surfaces, or the wrong application of thin layers.

Analytical Techniques for Adhesive Failure Analysis

- XPS Surface Analysis: Distinguishes silane coupling agents, dimethyl siloxane, silicates, and silica. Also used for seeing interfacial contaminants and providing sensitive measurement of silicones from our Silicone Contamination Detection Kits.

- FTIR Spectroscopy: Examines adhesive composition and detects thin layers of organic material. Useful for differences in chemistry at the bondline interface relative to bulk chemistry.

- GC-MS Analysis: Detects bonding failure causes with ppb testing capability. Helps identify additives and substances that might leak through to other layers.

- Optical Microscopy: Documents microscopic appearance associated with failure. Useful for finding areas for further analysis and getting results.

- Mechanical Testing: Measures tensile strength, lapshear strength, peel strength, and ability to bend. Provides data on adhesive bond performance.

- Thermal Analysis: Utilizes techniques like TMA and DSC to determine differences in thermal expansion, curing conditions, and degree of cure.

- Wavelength-Dispersive XRF Analysis: Measures carbon and nitrogen concentrations in adhesives and polymer adherends, useful in finding inorganic filler concentration.

Case Example: Adhesive Bonding Failure

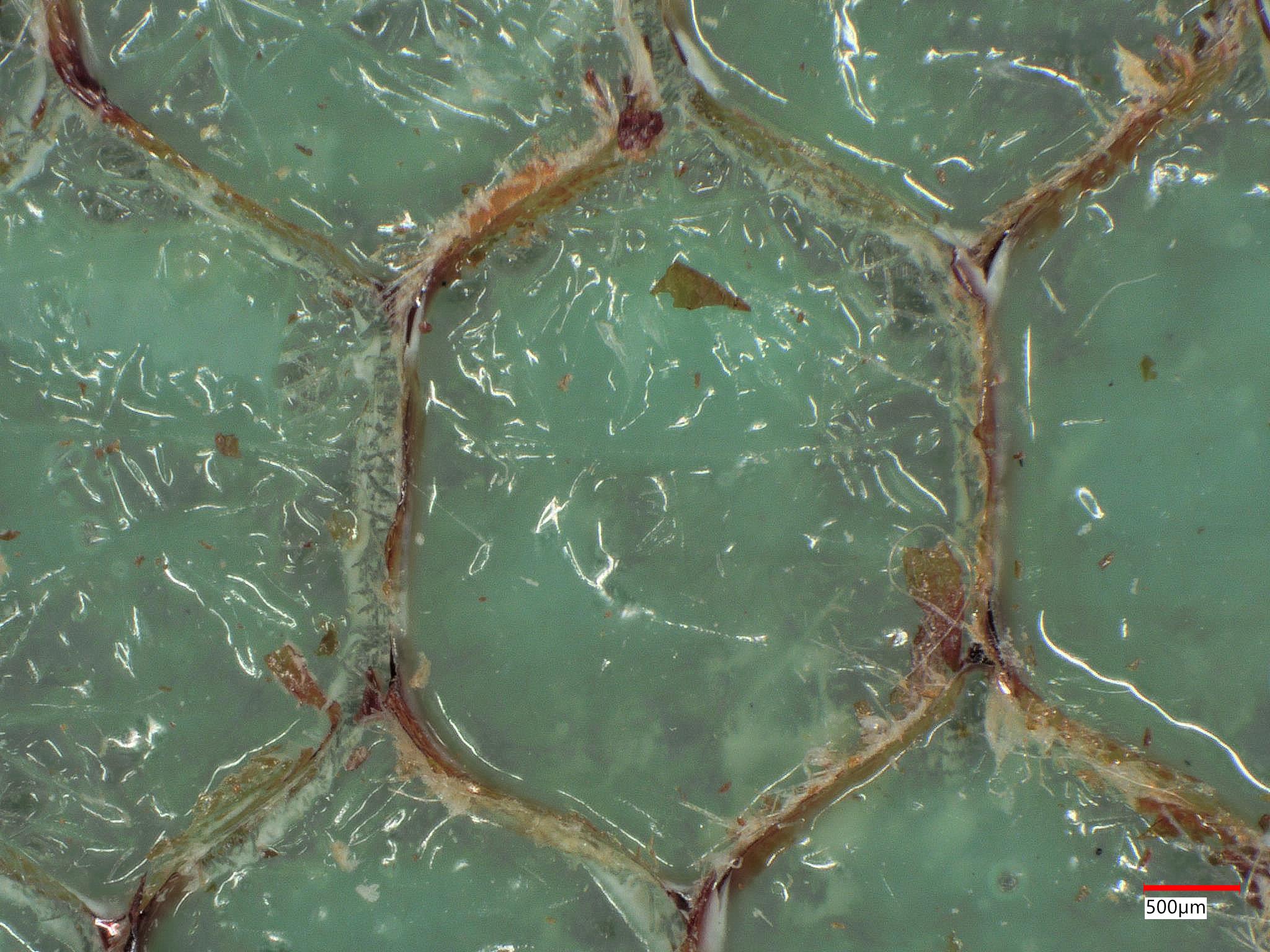

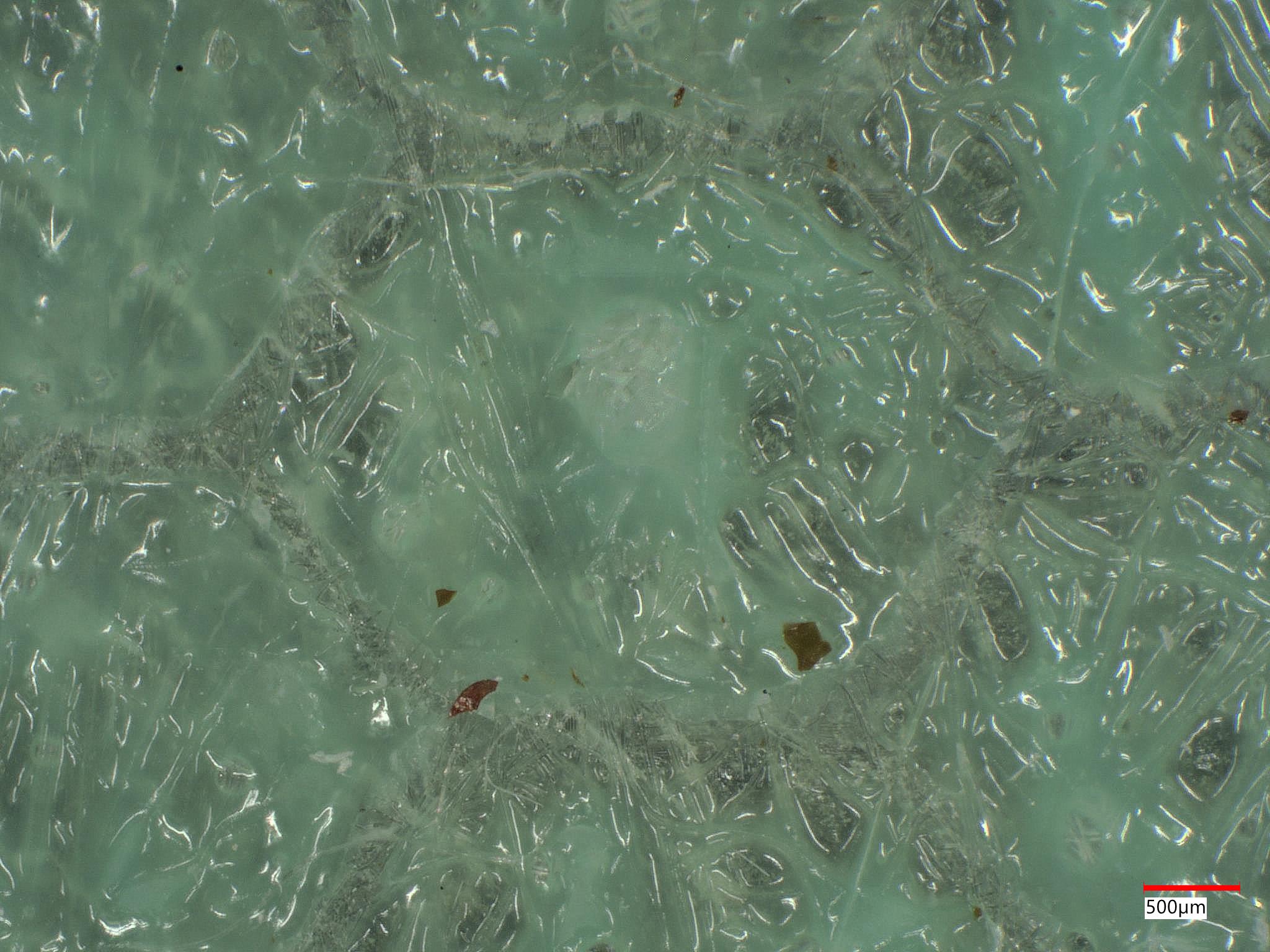

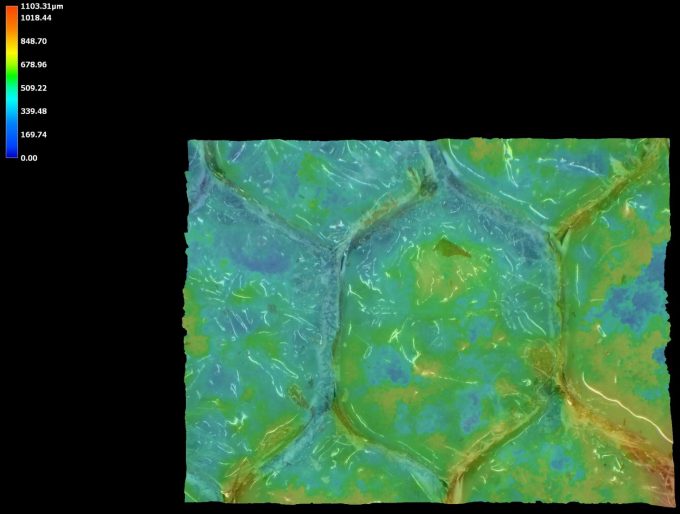

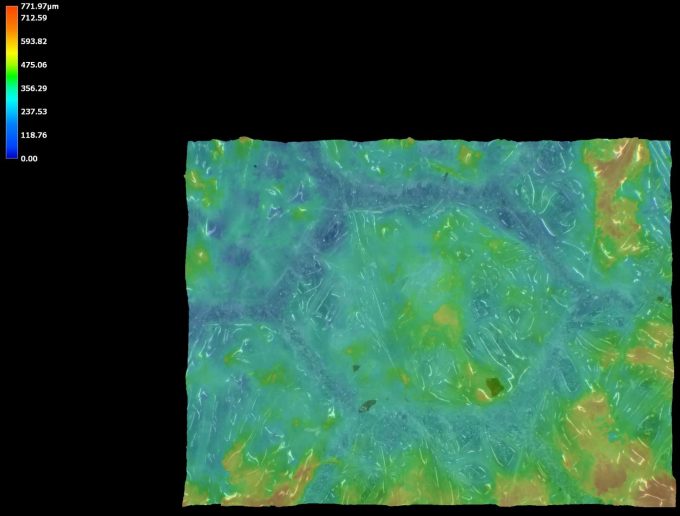

A client experienced bonding failure in an aramid honeycomb structure bonded to an epoxy board with fiberglass. XPS analysis determined contamination in the honeycomb structure led to the failure.

| Image Type | Successful Bonding Area | Failed Bonding Area |

|---|---|---|

| 3D 50X Keyence Ring Photo |  |  |

| Height Color Map |  |  |

Further Reading: Detailed Information on Adhesive Failure Analysis

For more insights into adhesive failure analysis techniques, case studies, and industry applications, visit our dedicated page on Adhesion Failures – An In Depth Look.